High hardness and wear-resistant WC-17Co ceramet coating formed through H13 steel surface supersonic flame spraying

A metal-ceramic coating, supersonic flame technology, applied in metal material coating process, coating, fusion spraying and other directions, can solve the problems of low hardness, short service life of mold, poor wear resistance, etc. The effect of low coefficient, high production efficiency and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1, WC-17Co cermet coating

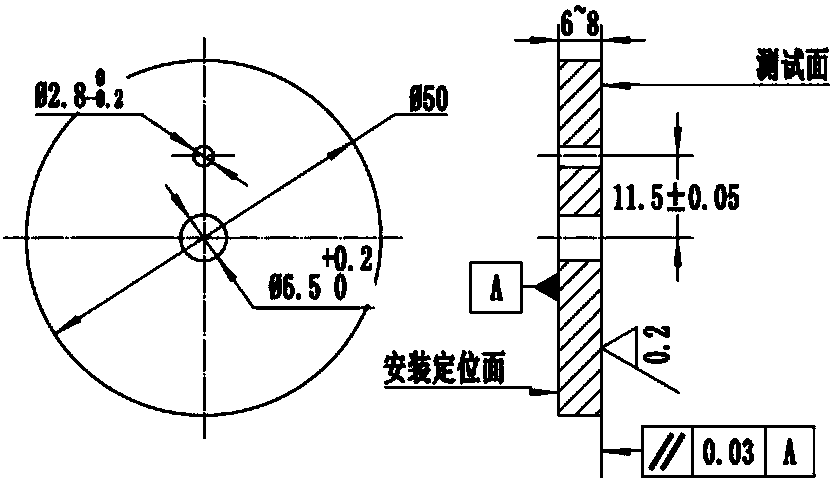

[0030] First, the size of H13 steel HVOF sprayed sample is Ф50×8mm, according to figure 1 Carry out finishing turning and longitudinal polishing. Next, use ethanol, use an ultrasonic cleaning machine to clean the oil on the surface of the H13 steel sample, and dry it for later use. Third, before HVOF spraying, the surface of H13 steel is pretreated by shot peening to improve the bonding strength between H13 steel substrate and HVOF coating. The technological parameters of shot peening are as follows: select ceramic shot, the distance between the nozzle and the H13 steel substrate is 200mm, the shot peening intensity is 0.3mmA, the spray angle is 90°, and the coverage rate is 100%. Finally, WC-17Co cermet composite coating was prepared on the surface of H13 steel by supersonic flame spraying process. The process parameters were: air flow rate 45L / min, oxygen flow rate 40L / min, propane flow rate 38L / min, powder f...

Embodiment 2

[0031] The preparation of embodiment 2, WC-17Co cermet coating

[0032] First, the size of H13 steel HVOF sprayed sample is Ф50×8mm, according to figure 1 Carry out finishing machining and longitudinal polishing treatment; secondly, use ethanol or acetone solution, use an ultrasonic cleaner to clean the oil stain on the surface of the H13 steel sample, and dry it for later use; thirdly, before the supersonic flame spraying, spray the H13 steel surface Shot pretreatment to improve the bond strength between H13 steel substrate and supersonic flame sprayed coating. The process parameters of shot peening are as follows: select ceramic shot, the distance between the nozzle and the H13 steel substrate is 200mm, the shot peening intensity is 0.3mmA, the spray angle is 90°, and the coverage rate is 100%. Prepare WC-17Co cermet overcoating on the steel surface. The process parameters are: air flow rate is 40L / min, oxygen flow rate is 35L / min, propane flow rate is 36L / min, powder feedi...

Embodiment 3

[0033] The preparation of embodiment 3, WC-17Co cermet coating

[0034] First, the size of H13 steel HVOF sprayed sample is Ф50×8mm, according to figure 1 Carry out finishing and polishing treatment; secondly, use ethanol or acetone solution, use an ultrasonic cleaner to clean the oil on the surface of the H13 steel sample, and dry it for later use; thirdly, spray the H13 steel surface Shot pretreatment to improve the bond strength between H13 steel substrate and supersonic flame sprayed coating. The process parameters of shot peening are: select ceramic shot, shot peening intensity is 0.3mmA, the distance between nozzle and H13 steel substrate is 200mm, the spray angle is 90°, and the coverage rate is 100%. Prepare WC-17Co cermet coating on the steel surface, the process parameters are: air flow rate is 50L / min, oxygen flow rate is 45L / min, propane flow rate is 40L / min, powder feeding rate is 45g / min, spraying distance is 330mm, among which The particle size of the WC-17Co ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com