A kind of open width mercerizing device and mercerizing method for cotton and weft plain knitted fabrics

A technology for flat knitted fabrics and mercerization, applied in the field of open-width mercerizing devices, can solve the problems of inability to effectively control the change of the knitted fabric loop shape, poor dimensional stability, large shrinkage rate, etc. Uniform and uniform effect of coil shape change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

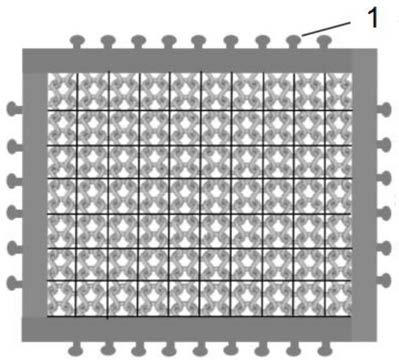

[0032] This embodiment provides a kind of open-width mercerizing device for cotton weft plain knitted fabric, see figure 1 and figure 2 , the device includes: two movable wooden frames 3 with scales, a clamp 2 and a regulator 1;

[0033] Wherein, the adjuster 1 is located outside the wooden frame 3 and is used to adjust the surface density of the cotton weft jersey fabric 4;

[0034] The two movable wooden frames 3 with scales are used to fix the cotton weft jersey 4, and the clamps 2 are used to clamp the two movable wooden frames 3 with scales.

[0035] In this embodiment, the adjuster is arranged outside the open-width mercerizing device. During the mercerizing process of the cotton weft plain knitted fabric, the mesh density of the cotton weft plain knitted fabric is adjusted by the adjuster 1 according to the tension requirement. For example, when the tension requirements are respectively For 4N, 6N, and 8N, the cotton weft jersey fabric should be expanded accordingly,...

Embodiment 2

[0037] This embodiment provides an open-width mercerizing method for cotton weft plain knitted fabrics, using the open-width mercerizing device described in Embodiment 1, and the method includes:

[0038] Select an adapted open-width mercerizing device according to the size of the cotton weft plain knitted fabric and place the cotton weft plain knitted fabric in the open-width mercerizing device to fix;

[0039] According to the requirements of the tension in the mercerizing process, adjust the mesh density of the cotton weft jersey through the regulator;

[0040] Put the open-width mercerizing device fixed with cotton weft plain knitted fabric in lye for mercerizing;

[0041] Wash the cotton weft plain knitted fabric in hot water at 50-70°C, then neutralize it in 1-3% acetic acid, then wash it in cold water, and dry it at room temperature;

[0042] Wherein, the lye is prepared by placing a sodium hydroxide solution with a concentration of 150 to 300 g / L in a mixed solution o...

Embodiment 3

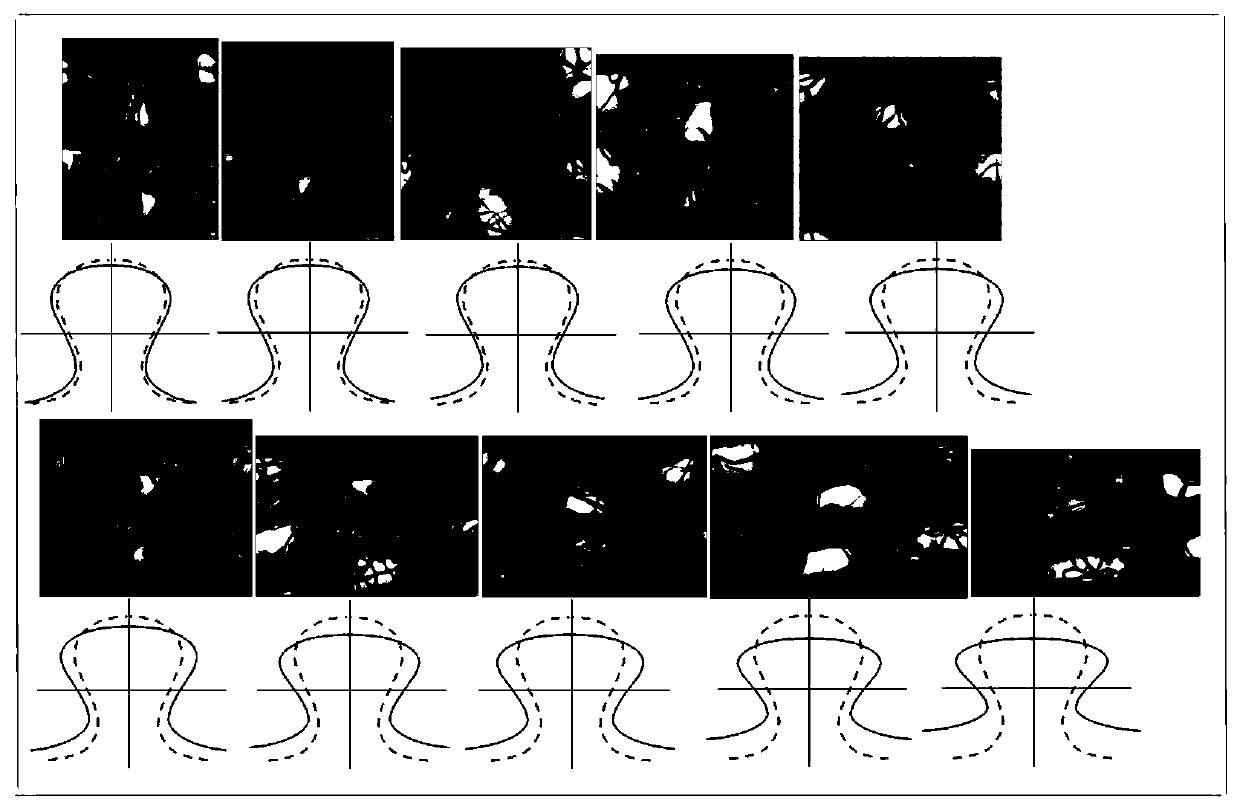

[0049] In this embodiment, the tension requirement in the mercerizing process is 6N as an example. Specifically, the inner diameter of the mercerizing frame is selected to be 21.2cm×21.2cm (corresponding to a tension of 6N), and the knitted fabric is fixed, and the mesh surface density is adjusted to 1.02cm× 0.8cm (latitudinal × radial, each containing 10 coils).

[0050] Sodium hydroxide is placed in the mixture of isopropanol-ethanol and water, the ratio of isopropanol to ethanol is 40%:60%, the volume ratio of isopropanol-ethanol to water is 85:15, the concentration of sodium hydroxide The solution is 250g / L, the solution is 3L, two parts are prepared, one part is lye temperature is 10 ℃, and the other part is lye temperature is 70 ℃, the shape of the coil is controlled by adjusting the tightness. Under the assistance of ultrasonic waves, the fabric to be treated is firstly treated with hot alkali for 20s, then placed in cold alkali solution for 50s, and finally placed in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com