Conductive washable graphene/silver composite cotton fabric and preparation method thereof

A technology of cotton fabric and graphene, which is applied in physical treatment, plant fiber, textile and paper making, etc. It can solve the problems of not being resistant to washing, poor conductivity, etc., and achieve the effect of improving quality, good dispersibility, and enhancing commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

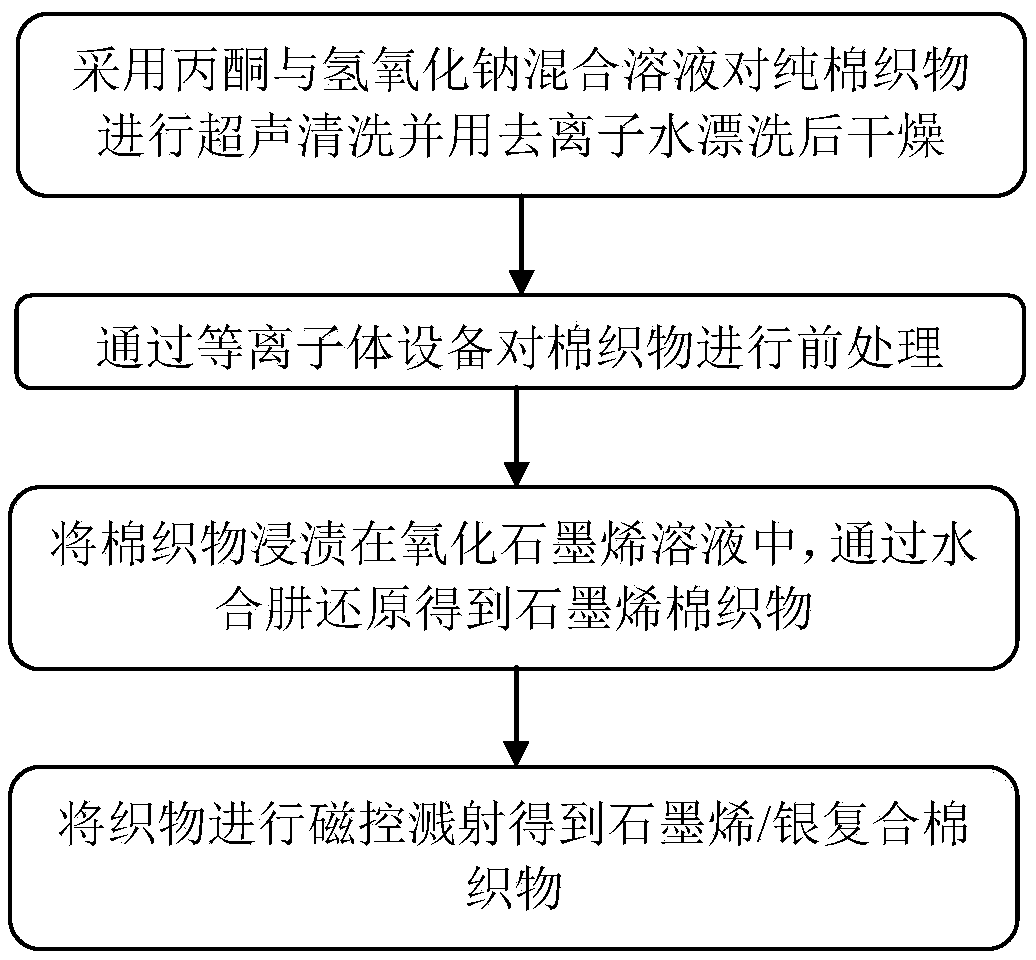

Method used

Image

Examples

Embodiment 1

[0034] 1. Plasma pretreatment of cotton fabrics: first immerse the pure cotton fabrics in an acetone solution dissolved with sodium hydroxide and clean them ultrasonically for 2 hours. The mass fraction of sodium hydroxide in the acetone solution is 50%, and then rinse with deionized water to remove the solvent, and then dried in an oven at 80°C for 5 hours. Then use low-temperature vacuum plasma equipment to modify the surface of the dried cotton fabric. The plasma modification parameters are: temperature 80 ° C, pressure 1.0 × 10 -3 Pa, the power supply is 250W, the processing time is 20min, and the ratio of oxygen to argon is 9:1.

[0035]2. Preparation of graphene cotton fabric: immerse the pretreated cotton fabric in a graphene oxide aqueous solution with a graphene oxide mass fraction of 1%, immerse in a constant temperature water bath at 100°C for 150min, the bath ratio of cotton fabric to graphene oxide aqueous solution 1:250, after the "one soaking and one rolling" p...

Embodiment 2

[0039] 1. Plasma pretreatment of cotton fabrics: first immerse the pure cotton fabrics in an acetone solution dissolved with sodium hydroxide and clean them ultrasonically for 4 hours. The mass fraction of sodium hydroxide in the acetone solution is 36%, and then rinse with deionized water to remove the solvent, and then dried in an oven at 60°C for 7 hours. Then use low-temperature vacuum plasma equipment to modify the surface of the dried cotton fabric. The plasma modification parameters are: temperature 70 ° C, pressure 2 × 10 -3 Pa, the power supply is 200W, the processing time is 15min, and the ratio of oxygen to argon is 4:1.

[0040] 2. Preparation of graphene cotton fabric: take out the pretreated cotton fabric and dip it in a graphene oxide aqueous solution with a graphene oxide mass fraction of 0.8%, immerse it in a constant temperature water bath at 80°C for 120min, and soak the cotton fabric and graphene oxide aqueous solution in a bath The ratio is 1:500. After t...

Embodiment 3

[0044] 1. Plasma pretreatment of cotton fabrics: first immerse the pure cotton fabrics in an acetone solution dissolved with sodium hydroxide and clean them ultrasonically for 2.5 hours. The mass fraction of sodium hydroxide in the acetone solution is 40%, and then rinse with deionized water to remove the solvent, and then dried in an oven at 80°C for 4 hours. Then use low-temperature vacuum plasma equipment to modify the surface of the dried cotton fabric. The plasma modification parameters are: temperature 65 ° C, pressure 2.5 × 10 -3 Pa, the power supply is 150W, the processing time is 10min, and the ratio of oxygen to argon is 7:3.

[0045] 2. Preparation of graphene cotton fabric: immerse the pretreated cotton fabric in a graphene oxide aqueous solution with a graphene oxide mass fraction of 0.6%, immerse in a constant temperature water bath at 60°C for 90 minutes, and the bath ratio of cotton fabric to graphene oxide aqueous solution 1:300, after the "one soaking and on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com