Process and device for jointly digesting total phosphorus and total nitrogen

A process and digestion cell technology, applied in the preparation of test samples, etc., can solve the problems of loose pipeline layout and mechanical parts layout, easy occurrence of dead ends, and large power consumption, so as to reduce the amount of test reagents and liquid discharge. , the effect of prolonging the maintenance cycle and reducing the operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take multiple organic standard samples, specifically sample 1 (total phosphorus concentration 0.050 mg / L, total nitrogen concentration 1.00 mg / L), sample 2 (total phosphorus concentration 0.200 mg / L, total nitrogen concentration 2.00 mg / L), sample Three (total phosphorus concentration 0.600 mg / L, total nitrogen concentration 4.00 mg / L);

[0039] Take 25mL of sample 1, add 5mL of K with a concentration of 0.15 mol / L to it 2 S 2 o 4 Solution and 1mL NaOH solution with a concentration of 0.75 mol / L, and sealed and digested at 120°C to 124°C for 25 minutes, after digestion, the liquid was discharged into spectral analysis for colorimetry, and the total nitrogen was measured as: 0.93mg / L; Add the total phosphorus color reagent, and perform colorimetry in the colorimetric analysis, and the measured total phosphorus is 0.049 mg / L;

[0040] Take 50mL of sample two, add 10mL of K with a concentration of 0.25 mol / L 2 S 2 o 4 Solution and 2mL NaOH solution with a concentrati...

Embodiment 2

[0046] Take multiple unknown samples, specifically sample four, sample five, and sample six.

[0047] Get 60mL sample 4, add 10mL concentration wherein to be the K of 0.2 mol / L 2 S 2 o 4 solution and 2mL NaOH solution with a concentration of 1.0mol / L and sealed and digested at 120°C to 124°C for 30 minutes. After digestion, the liquid was discharged into spectroscopic analysis for colorimetry. The total phosphorus color reagent was used for colorimetric analysis, and the measured total phosphorus was 0.049 mg / L.

[0048] Take 80mL sample five, add 10mL concentration to it and be the K of 0.15mol / L 2 S 2 o 4 solution and 2mL NaOH solution with a concentration of 0.75mol / L and sealed and digested at 120°C to 124°C for 40 minutes. The total phosphorus color reagent was used for colorimetric analysis, and the measured total phosphorus was 0.209mg / L.

[0049] Get 90mL sample 6, add 20mL concentration wherein is the K of 0.25mol / L 2 S 2 o 4 Solution and 5mL NaOH solution w...

Embodiment 3

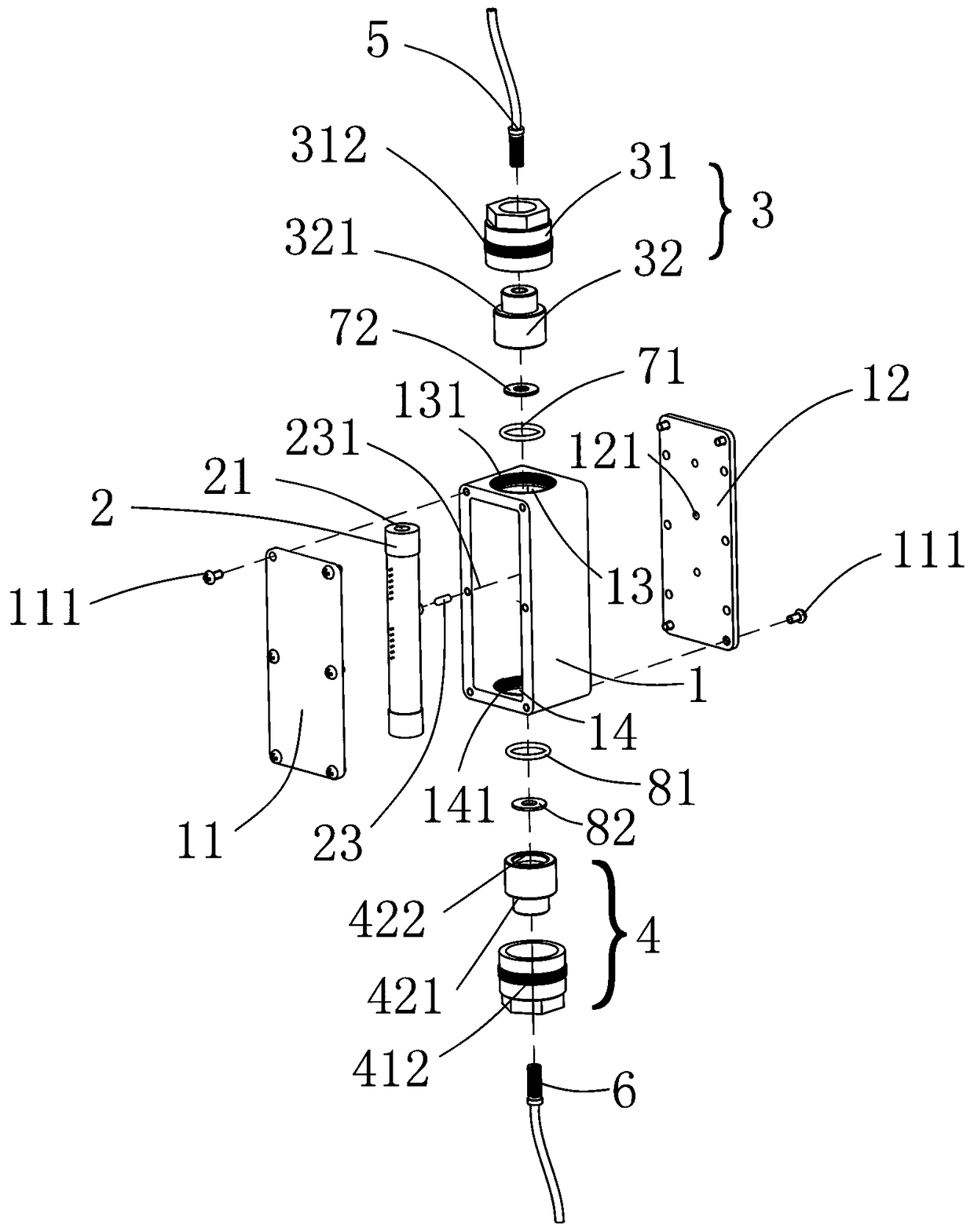

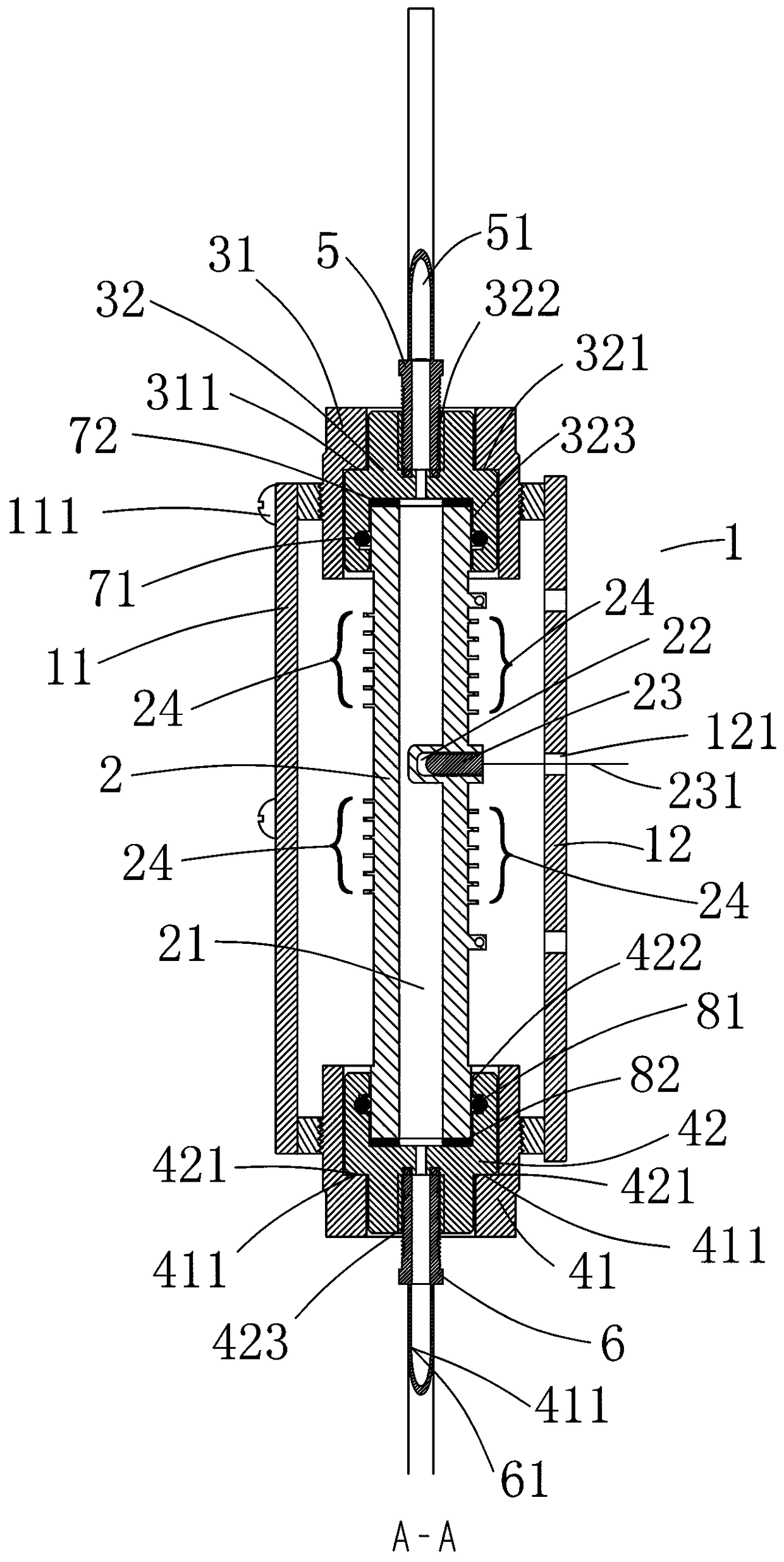

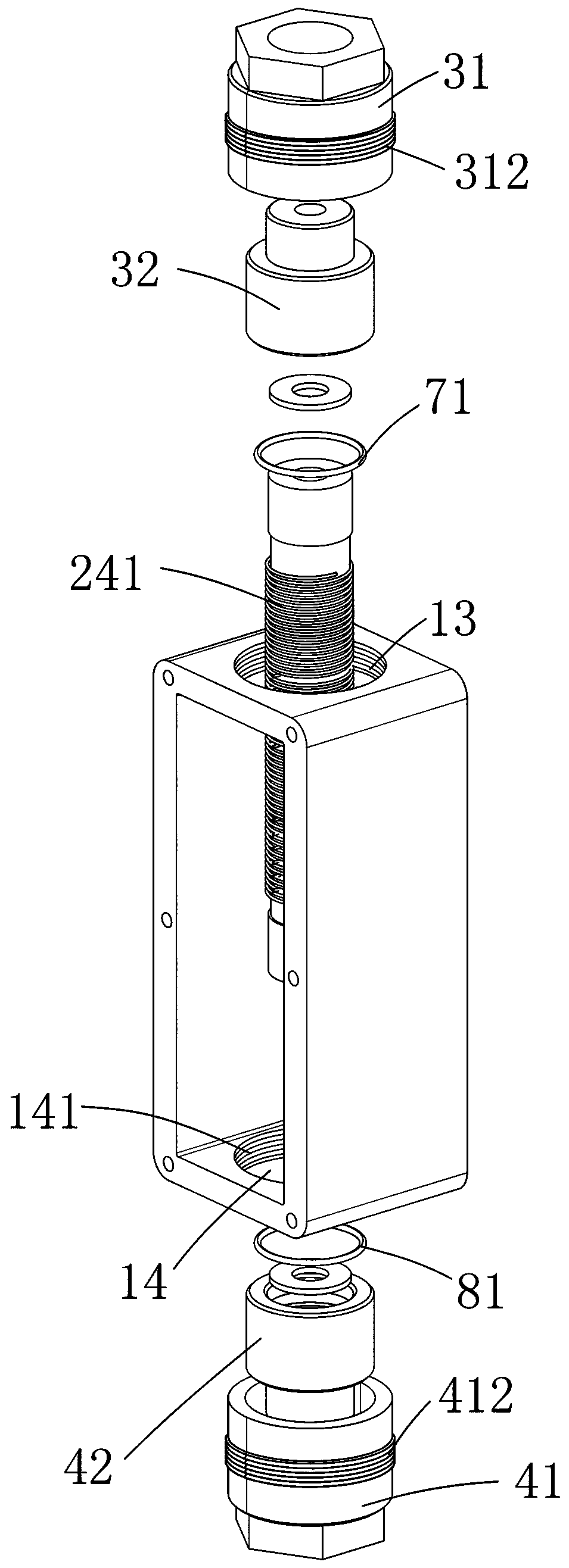

[0056] like figure 1 , figure 2 As shown, a device for combined digestion of total phosphorus and total nitrogen includes a digestion tank housing 1, a digestion tank 2, an upper sealing assembly 3, a lower sealing assembly 4, a water outlet 5 and a water inlet 6, wherein the digestion tank housing 1 is set There are a front cover 11 and a back plate 12, the front cover 11 and the back plate 12 are installed on the digestion tank shell 1 through bolts 111, and the back plate 12 is provided with perforations 121; the upper and lower sides of the digestion tank shell 1 are also provided with The connecting hole 13 and the lower connecting hole 14 are used to set the upper sealing assembly 3 and the lower sealing assembly 4 respectively. The upper sealing assembly 3 includes an upper metal briquetting block 31 and an upper sealing briquetting block 32. The upper metal briquetting block 31 is provided with a built-in step Surface 311 and the periphery are provided with external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com