A system for assemble and welding three-dimensional process planning

A technology of process design and welding, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve the problems of difficult design, high development cost, disconnection between process design and welding simulation, and improve the quality of product welding , Fast and low-cost design, the effect of improving the quality of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

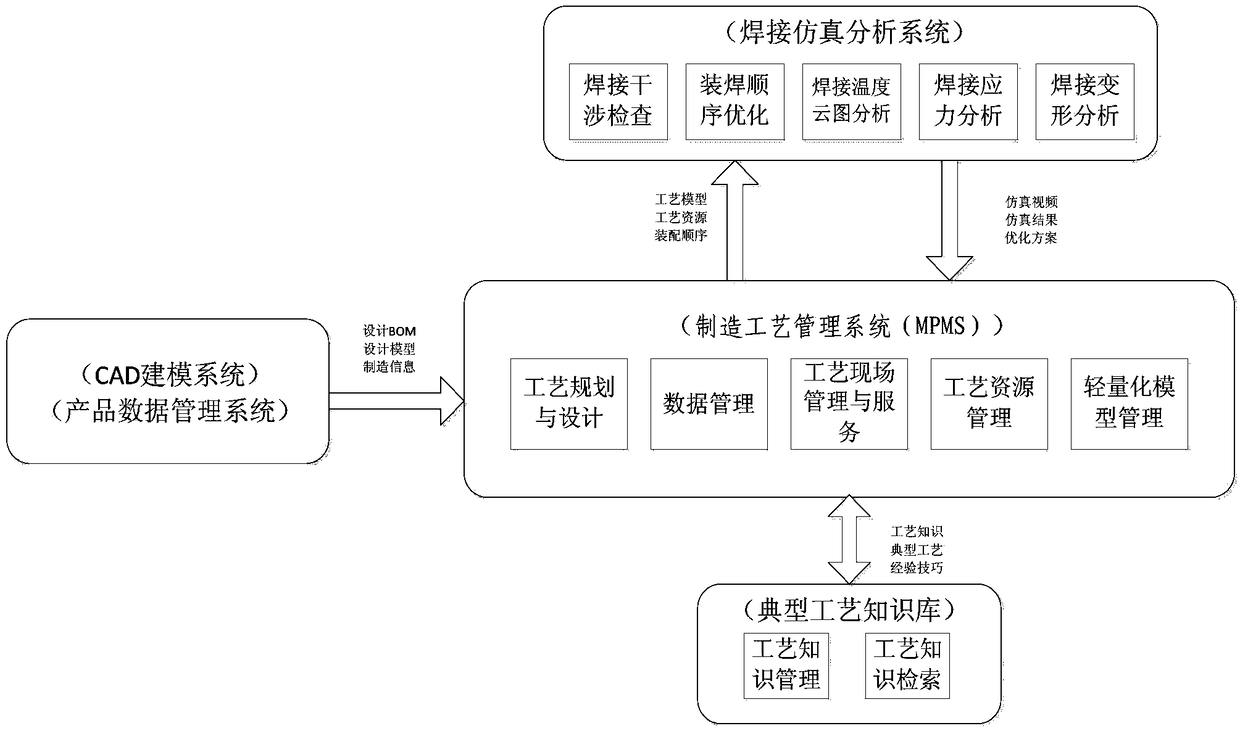

[0015] The invention provides a three-dimensional process design system for assembly and welding, which is integrated by a manufacturing process management system (MPMS), a CAD modeling system, a welding simulation analysis system, a product data management system and a typical process knowledge base;

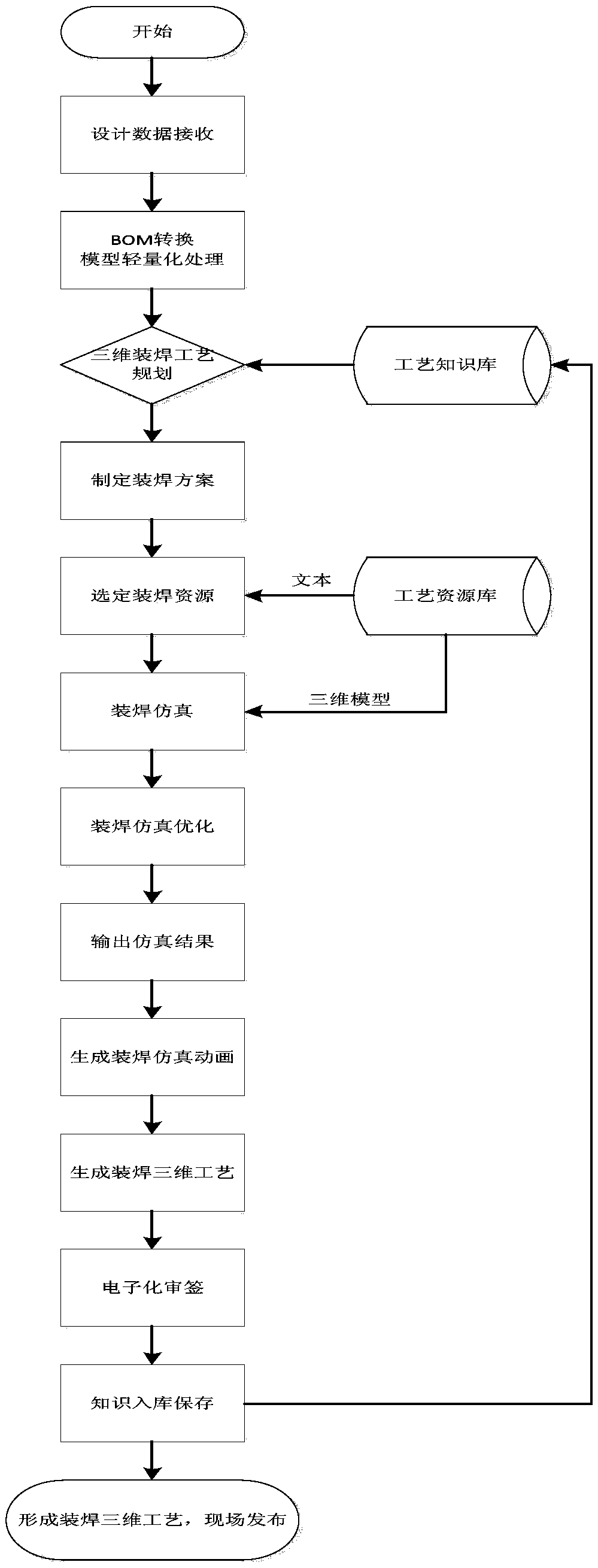

[0016] The manufacturing process management system is used to edit the product 3D design data in the product data management system, convert the product design BOM into a welding BOM, and carry out lightweight processing of the design data, and find the closest one by calling the typical process knowledge base. Assembly and welding plan, preliminarily formulate the welding plan, including the preset assembly and welding sequence, the welding content of specific stations combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com