Nitrogen-doped carbon anode material modified by nano tin and preparation method thereof

A nitrogen-doped carbon, anode material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low first coulombic efficiency and poor cycle life of tin-based anodes, and achieve cost Low, improved conductivity, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

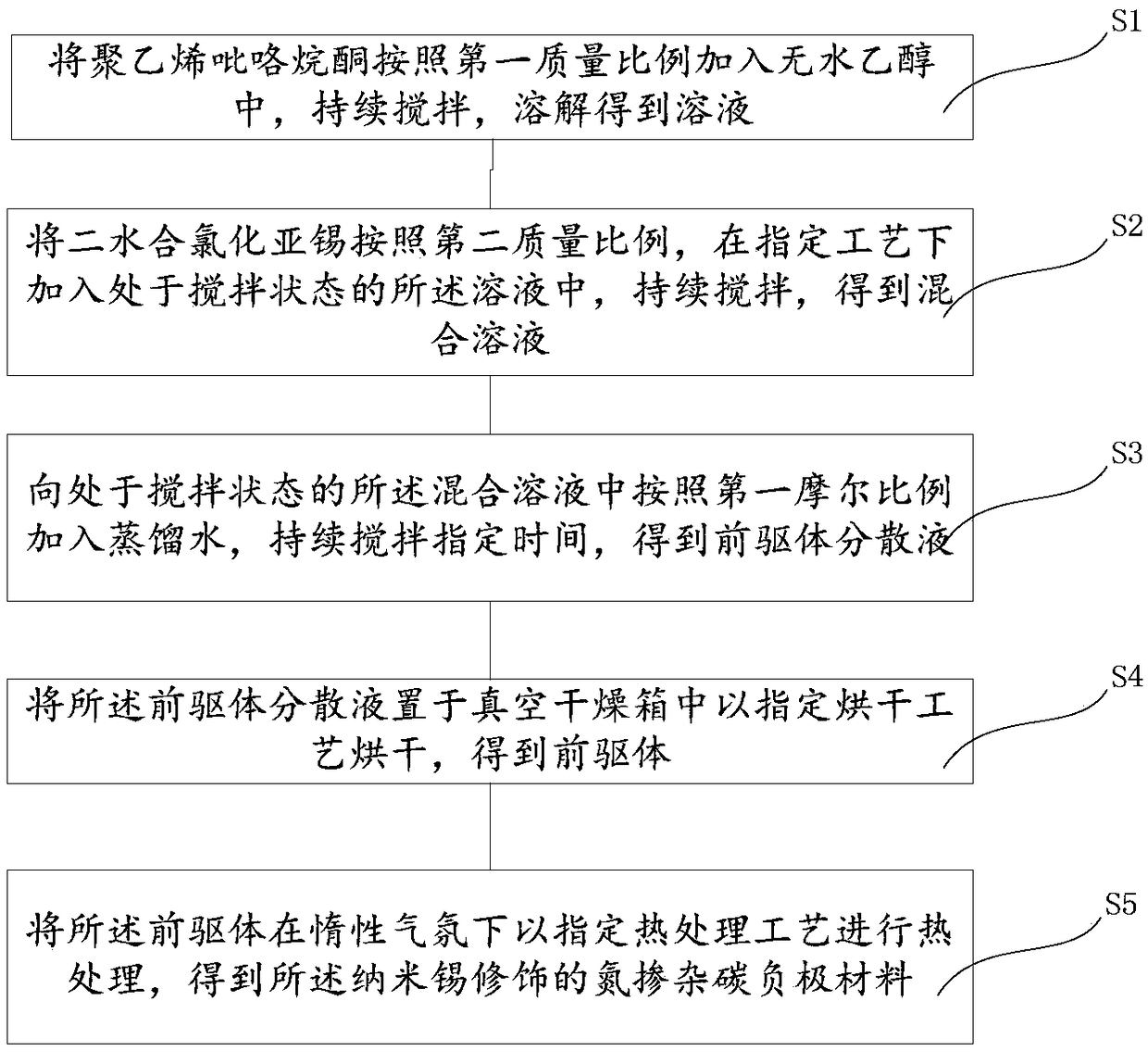

[0034] refer to figure 1 , the embodiment of the present invention proposes a method for preparing a nano-tin modified nitrogen-doped carbon negative electrode material, which is characterized in that it includes the following steps:

[0035] S1: adding polyvinylpyrrolidone into absolute ethanol according to the first mass ratio, stirring continuously, and dissolving to obtain a solution;

[0036] S2: adding stannous chloride dihydrate into the solution in a stirring state under a specified process according to the second mass ratio, and continuously stirring to obtain a mixed solution;

[0037] S3: Add distilled water to the mixed solution in the stirring state according to the first molar ratio, and continue stirring for a specified time to obtain a precursor dispersion;

[0038] S4: Put the precursor dispersion in a vacuum drying oven and dry it with a specified drying process to obtain a precursor;

[0039] S5: heat-treating the precursor in an inert atmosphere with a sp...

Embodiment 1

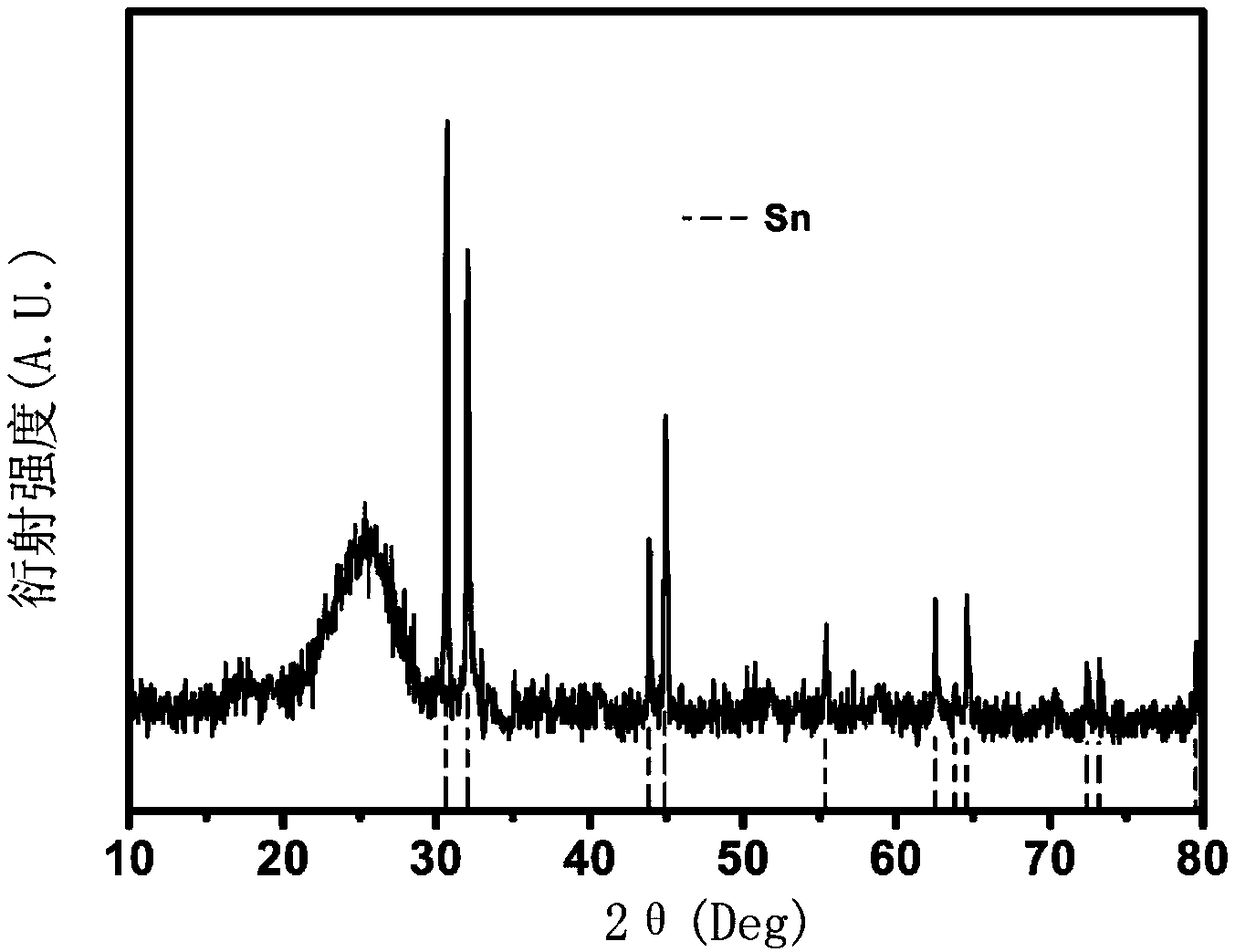

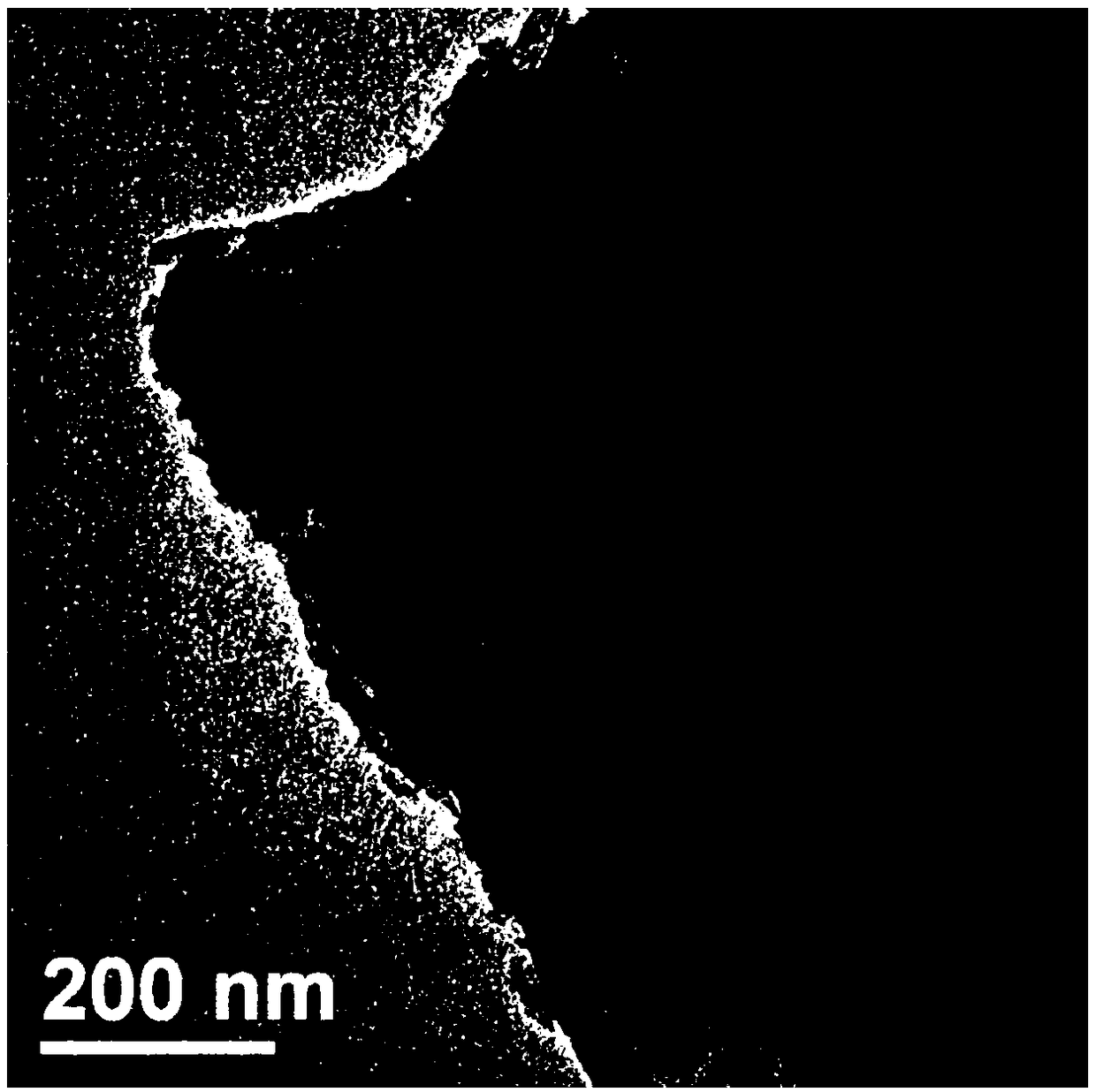

[0065] The nitrogen-doped carbon negative electrode material modified by nano-tin in this embodiment 1 (in the nitrogen-doped carbon negative electrode material modified by nano-tin in this embodiment 1, the mass fraction of tin element is 26wt%, and the atomic ratio of nitrogen and carbon is 2.7: 97.3) Preparation:

[0066] Step 1: Take 453mg of PVP and add it to 20mL of absolute ethanol, stir continuously at a stirring speed of 1000r / min, and dissolve to obtain a solution;

[0067] Step 2: 88mg SnCl 2 2H 2 O is quickly added in the solution of step 1 in a stirring state, and continuously stirred to obtain a mixed solution;

[0068] Step 3: Take 35.1uL of distilled water and add it to the mixed solution of Step 2 in a stirring state, and continue stirring for 6 hours to obtain a precursor dispersion;

[0069] Step 4: Dry the precursor dispersion obtained in Step 3 in a vacuum oven at 50°C for 12 hours to obtain the precursor of the target product;

[0070] Step 5: Under t...

Embodiment 2

[0074] The nitrogen-doped carbon negative electrode material of present embodiment 2 nano-tin modification (in the nitrogen-doped carbon negative electrode material of present embodiment 2 modification of nano-tin, the mass fraction of tin element is 5wt%, and the atomic ratio of nitrogen and carbon is 5.8: 94.2) Preparation:

[0075] Step 1: Add 1100mg of PVP into 15mL of absolute ethanol, and continue to stir at a stirring speed of 1500r / min to dissolve to obtain a solution;

[0076] Step 2: 43.8mg SnCl 2 2H 2 O is quickly added in the solution of step 1 in a stirring state, and continuously stirred to obtain a mixed solution;

[0077] Step 3: Take 69.8uL of distilled water and add it to the mixed solution of Step 2 in a stirring state, and stir for 0.5h to obtain a precursor dispersion;

[0078] Step 4: Dry the precursor dispersion obtained in Step 3 in a vacuum oven at 80°C for 24 hours to obtain the precursor of the target product;

[0079] Step 5: Under the protectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com