Titanium tantalate-based photocatalyst doped with niobium and vanadium as well as preparation method and application of titanium tantalate-based photocatalyst

A photocatalyst and tantalic acid technology, applied in the field of vanadium-based titanium tantalate-based photocatalyst, niobium doping, preparation, inorganic photocatalyst and its preparation, can solve the problems of dye sewage, water pollution, etc., to protect the environment, realize the Absorb and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

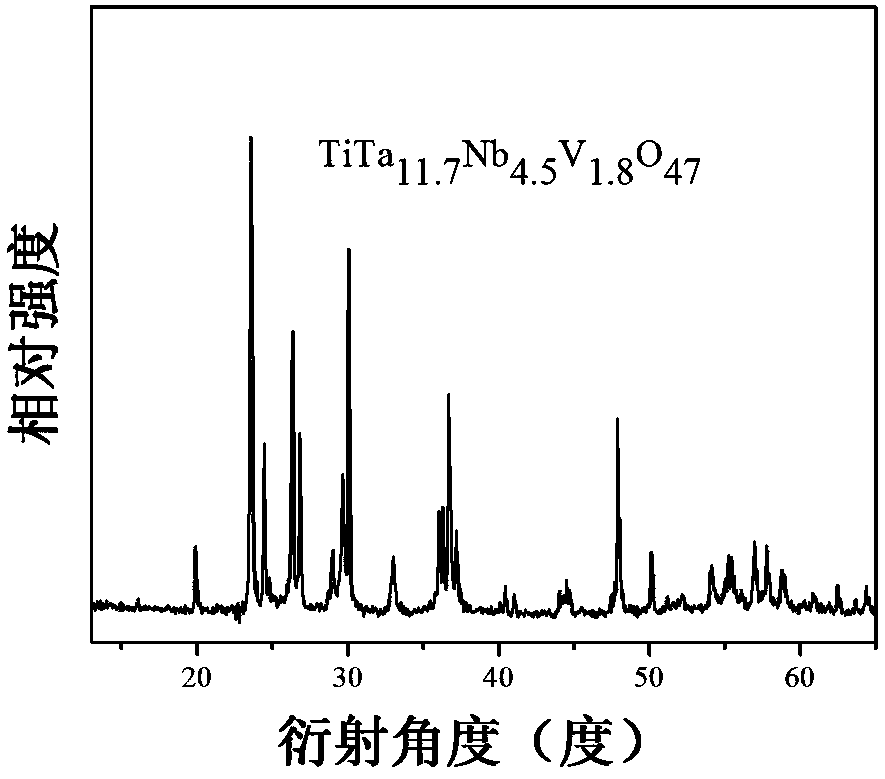

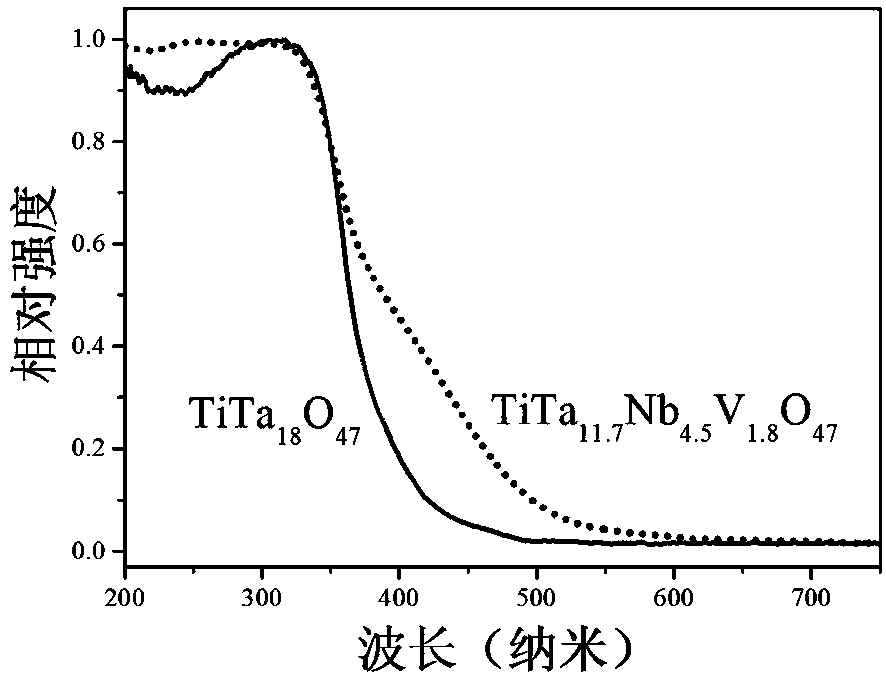

[0027] According to the chemical formula TiTa 11.7 Nb 4.5 V 1.8 o 47 The stoichiometric ratio of each element in , respectively weighed 0.2 grams of TiO 2 , 6.486 g Ta 2 o 5 , 1.49 g Nb 2 o 5 , 0.526 g NH 4 VO 3 ; Weigh 0.348 grams of Li 2 O as a sintering aid, grind and mix well.

[0028] The obtained mixture was pre-sintered for the first time in an air atmosphere at a sintering temperature of 650° C. for 6 hours, cooled naturally, ground and mixed uniformly.

[0029] The mixture obtained after the first pre-sintering is continued to be calcined for the second time in an air atmosphere, the calcining temperature is 850° C., the calcining time is 5 hours, cooled naturally, ground and mixed uniformly.

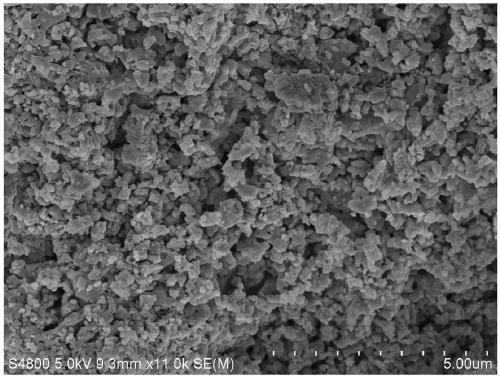

[0030] The mixture obtained after the second calcination was calcined for the third time in an air atmosphere, the calcination temperature was 1100°C, the calcination time was 8 hours, and cooled to room temperature to obtain powdery niobium Nb and vanadium V doped t...

Embodiment 2

[0038] According to the chemical formula TiTa 10.6 Nb 5.4 V 2 o 47 The stoichiometric ratio of each element in , respectively weighed 0.2 grams of TiO 2 , 9.493 g TaCl 5 , 3.588 g NbCl 5 , 0.455 g V 2 o 5 ; Weigh 0.13 grams of Li 2 CO 3 As a sintering aid, grind and mix well. The obtained mixture was pre-sintered for the first time in an air atmosphere at a sintering temperature of 650° C. for 6 hours, cooled naturally, ground and mixed uniformly. The mixture obtained after the first pre-sintering is continued to be calcined for the second time in an air atmosphere, the calcination temperature is 850°C, the calcination time is 5 hours, cooled naturally, ground and mixed uniformly; the mixture obtained after the second calcination Carry out the third calcination in an air atmosphere, the calcination temperature is 1100°C, the calcination time is 8 hours, and cooled to room temperature to obtain powdery niobium Nb and vanadium V doped titanium tantalate photocatalyst. ...

Embodiment 3

[0040] According to the chemical formula TiTa 17.8 Nb 0.1 V 0.1 o 47 The stoichiometric ratio of each element in, respectively weighed 0.399 grams of TiO 2 , 19.669 g Ta 2 o 5 , 0.067 g Nb 2 o 5 , 0.0665 g NH 4 VO 3 ; Weigh 0.196 grams of LiF as a sintering aid, grind and mix evenly. The obtained mixture was pre-sintered for the first time in an air atmosphere at a sintering temperature of 650° C. for 6 hours, cooled naturally, ground and mixed uniformly. The mixture obtained after the first pre-sintering is continued to be calcined for the second time in an air atmosphere, the calcination temperature is 850 ° C, the calcination time is 5 hours, cooled naturally, ground and mixed uniformly; the obtained after the second calcination The mixture was calcined for the third time in air atmosphere, the calcining temperature was 1100°C, the calcining time was 8 hours, and cooled to room temperature to obtain powdery niobium Nb and vanadium V doped titanium tantalate photoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com