Heterojunction photocatalyst and preparation method thereof

A photocatalyst and heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of photocatalytic hydrogen production efficiency and photocatalytic stability, few catalytic active centers, redox Poor ability and other problems, to achieve the effect of improving efficiency and photocatalytic stability, good redox ability, accelerating separation and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

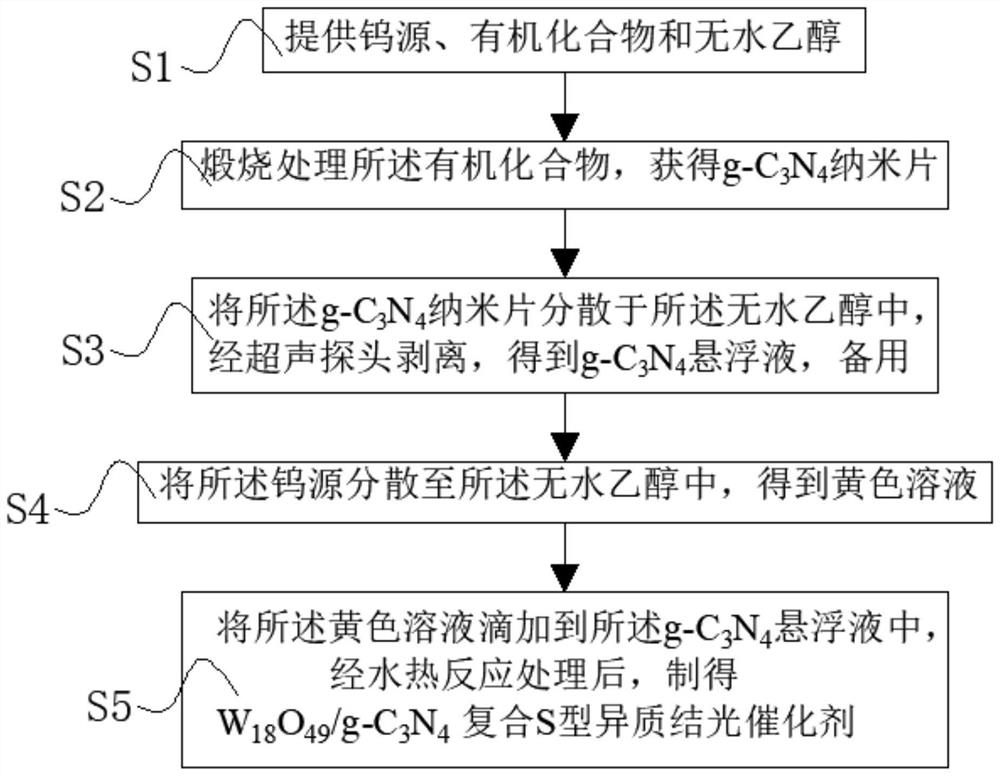

[0034] Please refer to figure 1 , the present invention provides a W 18 o 49 / g -C 3 N 4 The preparation method of composite S-type heterojunction photocatalyst comprises the following steps:

[0035] S1 provides tungsten sources, organic compounds and absolute ethanol.

[0036] The tungsten source can be tungsten hexachloride, tungsten pentachloride or tungsten pentabromide. The organic compound can be urea, thiourea, cyanamide, dicyandiamide or melamine, or a mixture formed by any combination of urea, thiourea, cyanamide, dicyandiamide and melamine.

[0037] S2 calcining the organic compound to obtain g-C 3 N 4 Nanosheets.

[0038] Fully grind the organic compound, then transfer it to a crucible, place the organic compound together with the crucible in a muffle furnace for calcination, and obtain g-C 3 N 4 Nanosheets. Wherein, the calcination treatment process is: heating to 450-650° C. and keeping the temperature for 1-4 hours. Synthetic g-C 3 N 4 For porous c...

Embodiment 1

[0049] This embodiment provides a W 18 o 49 / g -C 3 N 4 The preparation method of the composite S-type heterojunction photocatalyst comprises the following steps: fully grinding 10 g of urea and 3 g of thiourea for 30 min, and then transferring them to a 30 mL crucible. After that, it was placed in a muffle furnace and heated to 550°C for 90 minutes and kept for 2 hours to obtain ultra-thin g-C 3 N 4 Nanosheets. Take 0.24g ultra-thin g-C 3 N 4 The nanosheets were placed in 20mL of absolute ethanol and peeled off with an ultrasonic probe for 0.5h to obtain g-C 3 N 4 suspension. Dissolve 0.06 g of tungsten hexachloride in absolute ethanol under stirring conditions, and stir for 30 minutes to obtain a tungsten hexachloride solution. Add tungsten hexachloride solution dropwise to g-C 3 N 4 suspension, heated at 180°C for 2h, and then dried by centrifugation to obtain W 18 o 49 / g -C 3 N 4 Composite S-type heterojunction photocatalyst.

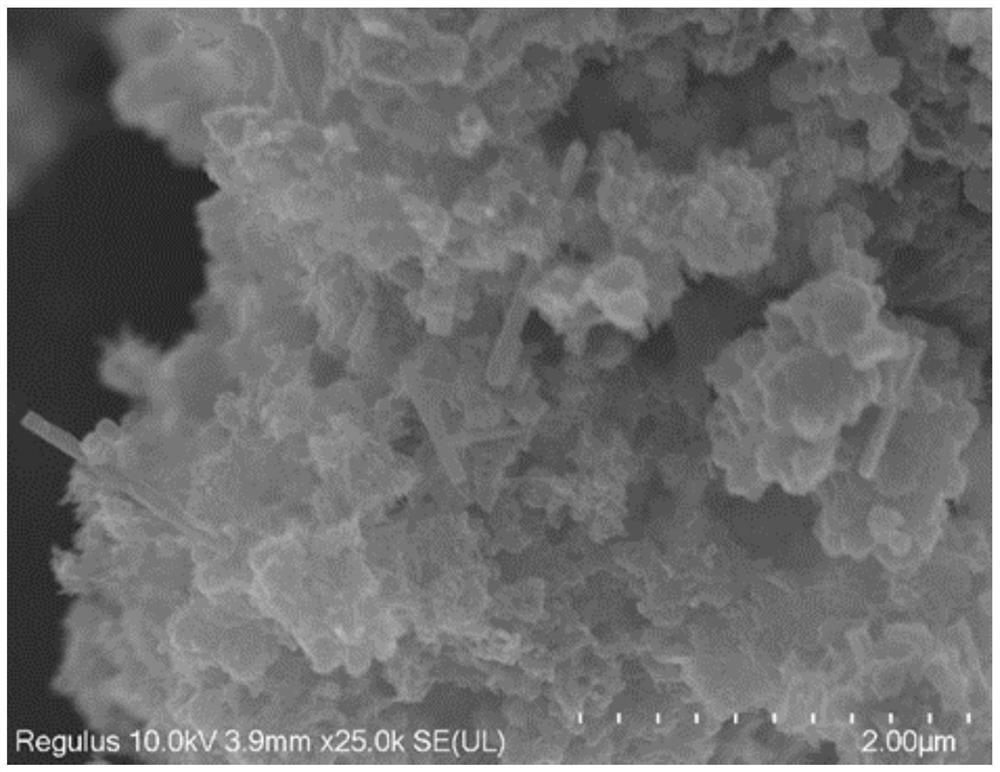

[0050] The W prepared in th...

Embodiment 2

[0053] The difference between this example and Example 1 is that in the preparation method: 20g of dicyandiamide and 5g of thiourea are fully ground for 30min. Place it in a muffle furnace and heat it to 450°C for 90 minutes and keep it warm for 6 hours. Take 0.21g ultra-thin g-C 3 N 4 The nanosheets were placed in 20 mL of absolute ethanol and peeled off with an ultrasonic probe for 1 h. Dissolve 0.12g of tungsten pentabromide in absolute ethanol to obtain a tungsten pentabromide solution, and add the tungsten pentabromide solution dropwise to g-C 3 N 4 The suspension was heated at 200°C for 1h.

[0054] The W prepared in this example 18 o 49 / g -C 3 N 4 The composite S-type heterojunction photocatalyst was used in photocatalytic hydrogen production, and the hydrogen production was measured after a period of photocatalytic reaction. After testing, the W prepared in this example 18 o 49 / g -C 3 N 4 The hydrogen production rate of the composite S-type heterojunctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com