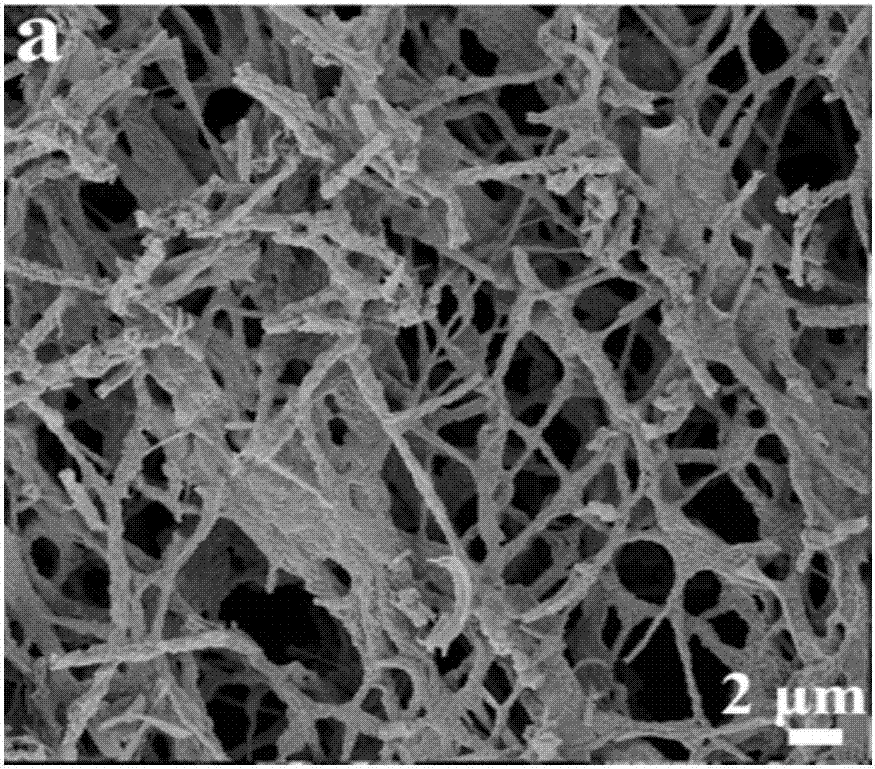

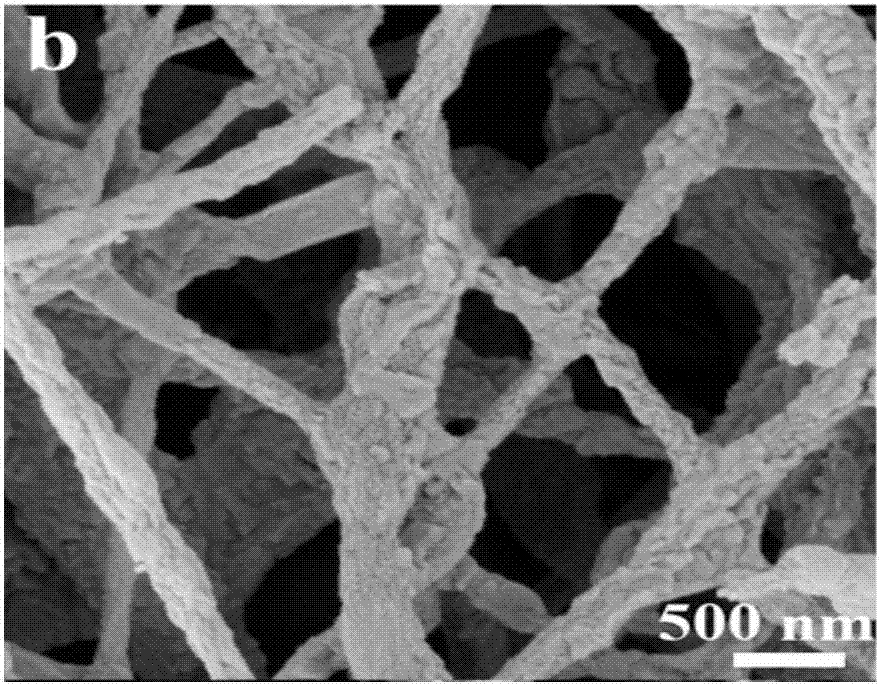

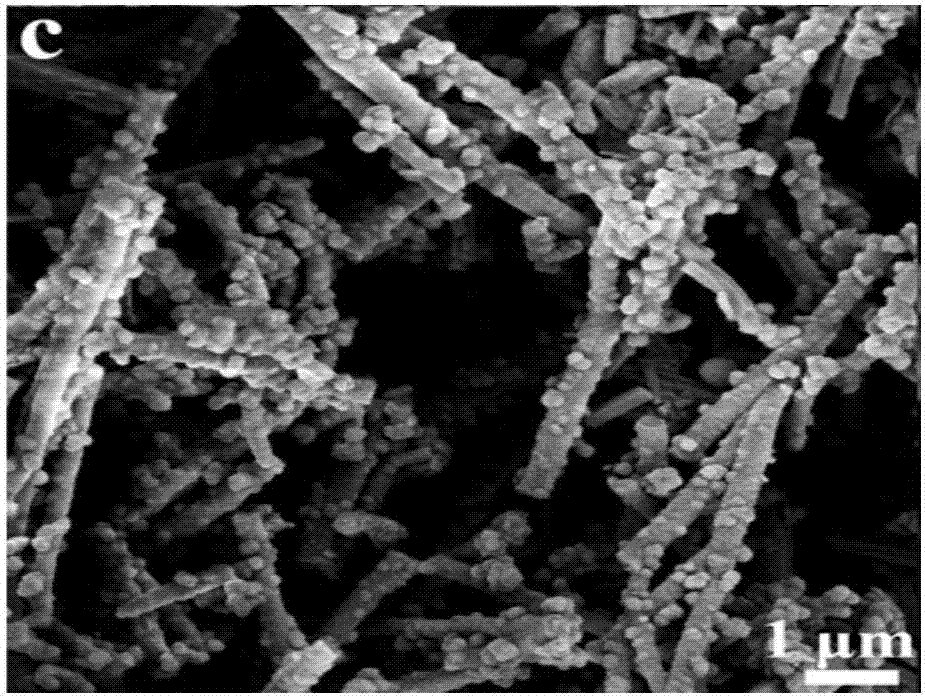

Copper phthalocyanine/gamma-bismuth molybdate composite nanofiber photocatalytic material and preparation method and application thereof

A technology of composite nanofibers and photocatalytic materials, which is applied in the field of photocatalytic materials, can solve the problems of difficult recycling and reuse, high application cost, unfavorable transmission and separation of photogenerated carriers, and achieve improved photocatalytic efficiency, favorable transmission and Effect of separation and enhancement of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of copper phthalocyanine / γ-bismuth molybdate composite nanofiber photocatalytic material, comprising the following steps:

[0065] (1) Preparation of spinnable precursor sol: at room temperature, dissolve 1.0 g of citric acid into 8 ml of deionized water and stir until dissolved; then add 0.177 g of ammonium molybdate and 0.970 g of bismuth nitrate pentahydrate to the above Add 1.6ml of concentrated nitric acid with a mass fraction of 68% to the solution, and stir at room temperature for 2 hours to obtain a clear and transparent solution B; add 3ml of solution B and 1.5ml of concentrated nitric acid with a mass fraction of 68% to 15ml of absolute ethanol, and mix at room temperature A solution D was uniformly obtained; 1.2 g of polyvinylpyrrolidone (PVP, K-90) was dissolved in the above solution D, and stirred at room temperature for 15 hours to obtain a spinnable precursor sol.

[0066] (2) Preparation of γ-bismuth molybdate nanofibers: transfer th...

Embodiment 2

[0070] A preparation method of copper phthalocyanine / γ-bismuth molybdate composite nanofiber photocatalytic material, comprising the following steps:

[0071] (1) Preparation of spinnable precursor sol: at room temperature, dissolve 2.5g of citric acid into 20ml of deionized water, stir until dissolved; then add 0.442g of ammonium molybdate and 2.425g of bismuth nitrate pentahydrate to the above To the solution, 3 ml of concentrated hydrochloric acid with a mass fraction of 37% was added, and a clear and transparent solution B was obtained after stirring at room temperature for 1 h. Add 2ml of solution B and 1.0ml of concentrated hydrochloric acid with a mass fraction of 37% into 10ml of absolute ethanol, and mix uniformly at room temperature to obtain solution D; dissolve 0.75g of polyvinylpyrrolidone (PVP, K-90) in the above solution D, After stirring at room temperature for 12 hours, the spinnable precursor sol was obtained.

[0072] (2) Preparation of γ-bismuth molybdate ...

Embodiment 3

[0077] A preparation method of copper phthalocyanine / γ-bismuth molybdate composite nanofiber photocatalytic material, comprising the following steps:

[0078] (1) Preparation of spinnable precursor sol: at room temperature, dissolve 2g of citric acid into 16ml of deionized water, stir until dissolved; then add 0.353g of ammonium molybdate and 1.94g of bismuth nitrate pentahydrate to the above solution 2 ml of concentrated hydrochloric acid with a mass fraction of 37% was added, and a clear and transparent solution B was obtained after stirring at room temperature for 4 h. Add 2ml of solution B and 2.0ml of concentrated hydrochloric acid with a mass fraction of 37% to 8ml of absolute ethanol, mix well at room temperature to obtain solution D; dissolve 1g of polyvinylpyrrolidone (PVP, K-90) in the above solution D, and After stirring for 24 hours, the spinnable precursor sol was obtained.

[0079] (2) Preparation of γ-bismuth molybdate nanofibers: transfer the spinnable precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com