Ultrathin wearing layer normal-temperature asphalt modifier and preparation method thereof

A technology of normal temperature asphalt and wearing course, which is applied in the direction of building insulation materials, building components, buildings, etc., and can solve the problem of reduced adhesion between the ultra-thin wearing course and the underlying pavement, difficult control of construction quality, and easy loss of aggregate temperature, etc. problems, to achieve the effect of saving engineering funds, low mixing temperature parameters, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

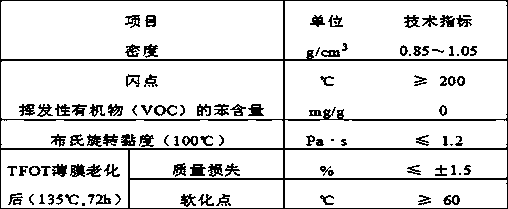

Image

Examples

Embodiment 1

[0027] A normal-temperature bitumen modifier for an ultra-thin wear layer, comprising 57 parts of cyclooctane, 30 parts of modified epoxy resin glue, 0.7 part of glyceryl monostearate, and 5 parts of a coordination titanate coupling agent.

[0028] Preparation:

[0029] 1) Add cyclooctane, modified epoxy resin glue, and glycerol monostearate into the stirring tank, heat up to 105°C, mix and stir evenly, and stir for 5.5 hours;

[0030] 2) Put the coordination titanate coupling agent into the material and continue to stir for 5 hours. After mixing and stirring evenly, the macromolecular polymer miscible product is the room temperature asphalt modifier for ultra-thin wear layer.

Embodiment 2

[0031] Example 2: A normal-temperature asphalt modifier for an ultra-thin wear layer, 65 parts of cyclooctane, 35 parts of modified epoxy resin glue, 1 part of glyceryl monostearate, 9 parts of glyceryl tristearate, Coordination titanate coupling agent.

[0032] Production Method:

[0033] 1) Add cyclooctane, modified epoxy resin glue, glyceryl monostearate and glyceryl tristearate into the stirring tank, raise the temperature to 103°C, mix and stir evenly, and the stirring time is 4.5 hours;

[0034] 2) Put the coordination titanate coupling agent into the material and continue to stir for 6 hours. After mixing and stirring evenly, the macromolecular polymer miscible product is the room temperature asphalt modifier for ultra-thin wear layer.

[0035] The above-mentioned cyclooctane is produced by Inner Mongolia Yili Chemical Industry Co., Ltd.;

[0036] Modified epoxy resin glue is produced by Inner Mongolia Yili Chemical Industry Co., Ltd.;

[0037] Glyceryl monostearate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com