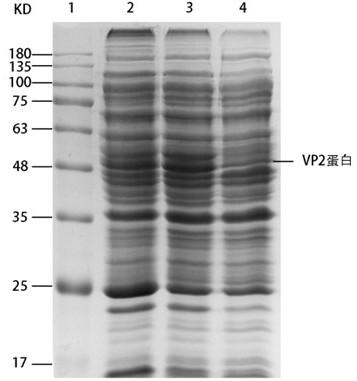

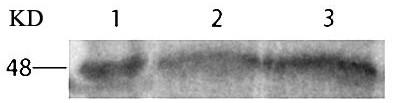

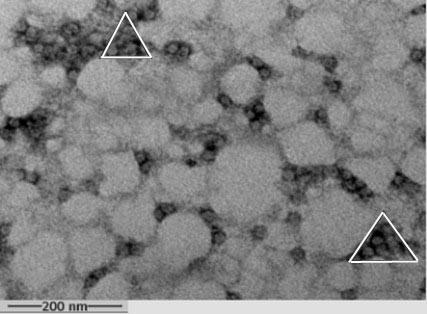

High-expression fermentation process of avian bursa virus VP2 protein

A fermentation process and high expression technology, applied in fermentation, virus, viral peptides and other directions, can solve the problems of difficult to achieve industrial production application, unsatisfactory VP2 protein expression, and purification that consumes a lot of manpower, material and financial resources, and achieves good commercial development. Value, improve market competitiveness, shorten the effect of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Construction test of genetically engineered bacteria

[0045] Referring to the Chinese patent document CN 106148358 A, the genetically engineered bacteria E.coli BL21(DE3)PlysS / pET-28a-IBDV-VP2 was constructed and stored in a glycerol tube at -80°C.

Embodiment 2

[0046] Embodiment 2: 10L fermentation test of genetically engineered bacteria

[0047] (1) Activation of strains

[0048] The genetically engineered bacteria preserved in the -80°C glycerol tube in Example 1 with an inoculation loop E. coli The BL21(DE3)PlysS / pET-28a-IBDV-VP2 strain was inoculated by streaking on the surface of LB solid medium containing kanamycin, and then the plate was cultured upside down in a constant temperature incubator at 37°C overnight.

[0049] (2) Seed cultivation

[0050] 1. Inoculate the activated bacterial classification into 50mL of primary seed medium, shake and cultivate at 37°C for 14 hours to obtain primary seed liquid;

[0051] Among them, the primary seed medium is LB medium, and its components are: 10g / L peptone, 5g / L yeast extract, 10g / L sodium chloride, sodium hydroxide solution or dilute hydrochloric acid to adjust the pH value to 7.0. 121 Sterilize at ℃ for 20 minutes, and add kanamycin at a concentration of 100ug / mL before inocula...

Embodiment 3

[0067] Embodiment 3: 100L fermentation test of genetically engineered bacteria

[0068] (1) Activation of strains

[0069] The genetically engineered bacteria preserved in the -80°C glycerol tube in Example 1 with an inoculation loop E. coli The BL21(DE3)PlysS / pET-28a-IBDV-VP2 strain was inoculated by streaking on the surface of LB solid medium containing kanamycin, and then the plate was cultured upside down in a constant temperature incubator at 37°C overnight.

[0070] (2) Seed cultivation

[0071] 1. Inoculate the activated bacterial classification into 500mL of primary seed culture medium, shake and cultivate at 37°C for 14 hours to obtain primary seed liquid;

[0072] Among them, the primary seed medium is LB medium, and its components are: 10g / L peptone, 5g / L yeast extract, 10g / L sodium chloride, and sodium hydroxide solution to adjust the pH value to 7.0. Sterilize at 121°C 20min, add kanamycin at a concentration of 100ug / mL before inoculation.

[0073] II. Transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry cell weight | aaaaa | aaaaa |

| Dry cell weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com