1550MPa-level spring flat steel and production method thereof

A flat steel and molten steel technology, applied in 1550MPa spring flat steel and its production field, can solve the problems of poor tempering resistance, failure to meet the requirements of high-end users, low Si content in steel, etc., to increase strength and improve decarburization Sensitivity, effects of increasing strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

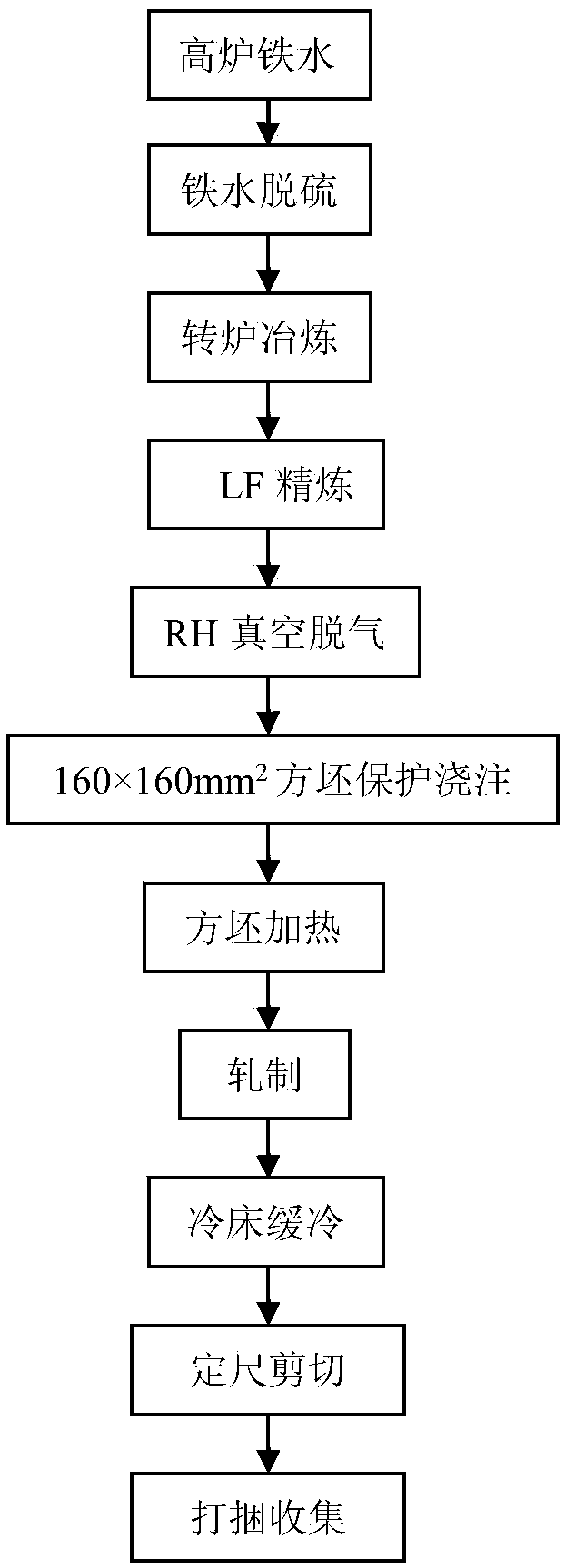

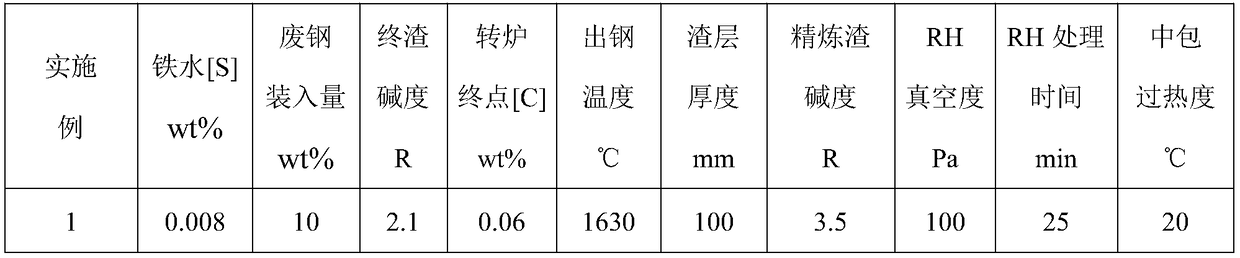

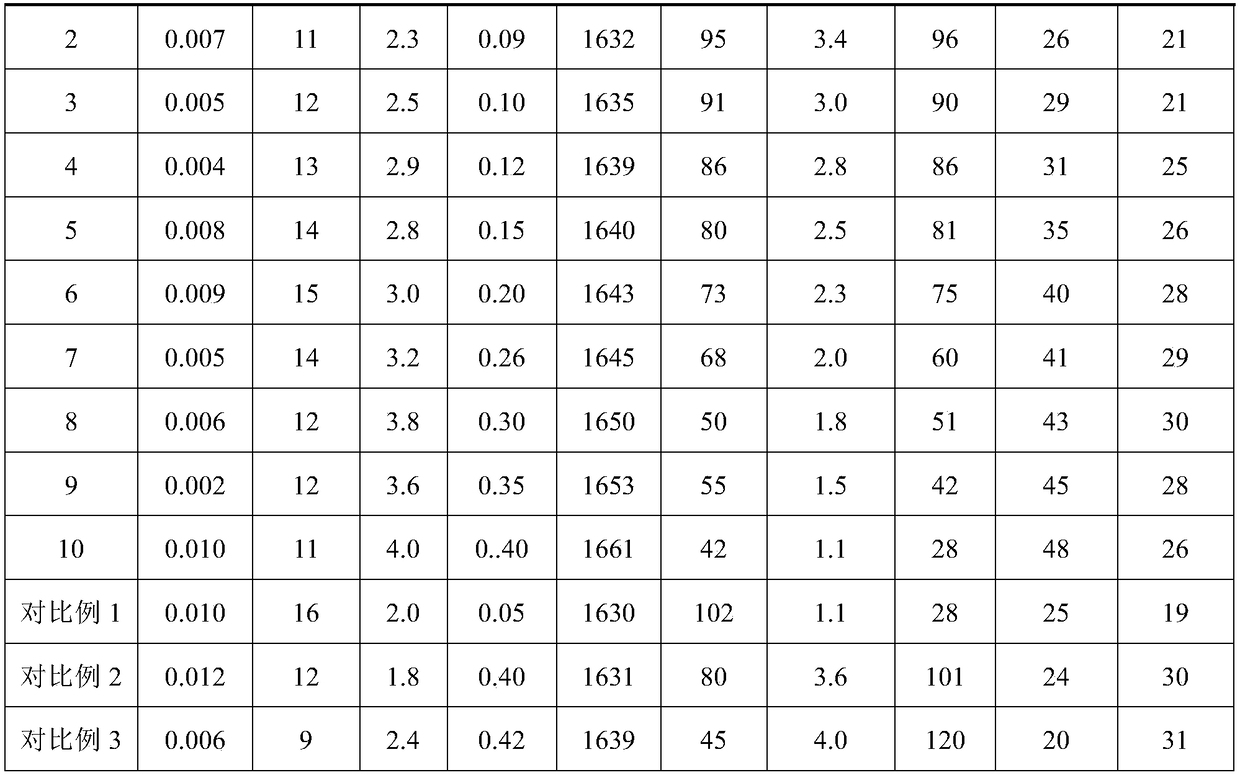

[0046] The schematic diagram of the production process of the 1550MPa grade spring flat steel described in embodiments 1 to 10 is shown in figure 1 , including the following steps: molten iron desulfurization, converter smelting, LF refining, vacuum treatment, protective continuous casting, slab heating, rolling, cooling bed controlled cooling, pit entry slow cooling, the specific steps and process parameters are:

[0047] 1) Desulfurization of molten iron, using magnesium powder desulfurization process, controlling the S content [S] of molten iron out of the station to ≤0.01%, and removing the desulfurization slag in the tank;

[0048] 2) The amount of steel scrap loaded into the converter accounts for 10-15% of the total amount loaded; the converter adopts top-bottom compound blowing, and the end point adopts a high-drawing supplementary blowing process; the basicity of the final slag is ≥2.1; the control target of the end point C of the converter is ≥0.06~ 0.40%; tapping te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com