Etching station aluminum anode oxidation component regeneration preparation technology

A technology of anodizing and preparation process, applied in the direction of anodizing, metal material coating process, superimposed layer plating, etc., can solve the problems of increased maintenance cost, increased component loss, poor adsorption capacity, etc., to increase the number of repeated regenerations , Avoid loss and deformation, reduce the effect of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The process for preparing the regeneration of the aluminum parts of the etching machine of the present invention comprises the following steps

[0031] Step 1: Degreasing: Degreasing the aluminum parts, the concentration of the degreasing agent is 30-60g / L, the temperature is 40-60°C, and the degreasing time is 4-8min;

[0032] Step 2: Alkali etching: put the degreased aluminum parts into NaOH solution for alkali etching, the concentration of alkali solution is 40-80g / L, the temperature is 40-60°C, and the alkali etching time is 10-20S;

[0033] Step 3: Deashing: put the parts after alkali etching into HNO3 solution to remove ash, the concentration of HNO3 is 30wt% ~ 50wt%, and the ash removal time is 30 ~ 50S;

[0034] Step 4: Washing: Rinse the surface of the component with deionized water for 3 to 5 times, each time for 30 to 50 seconds;

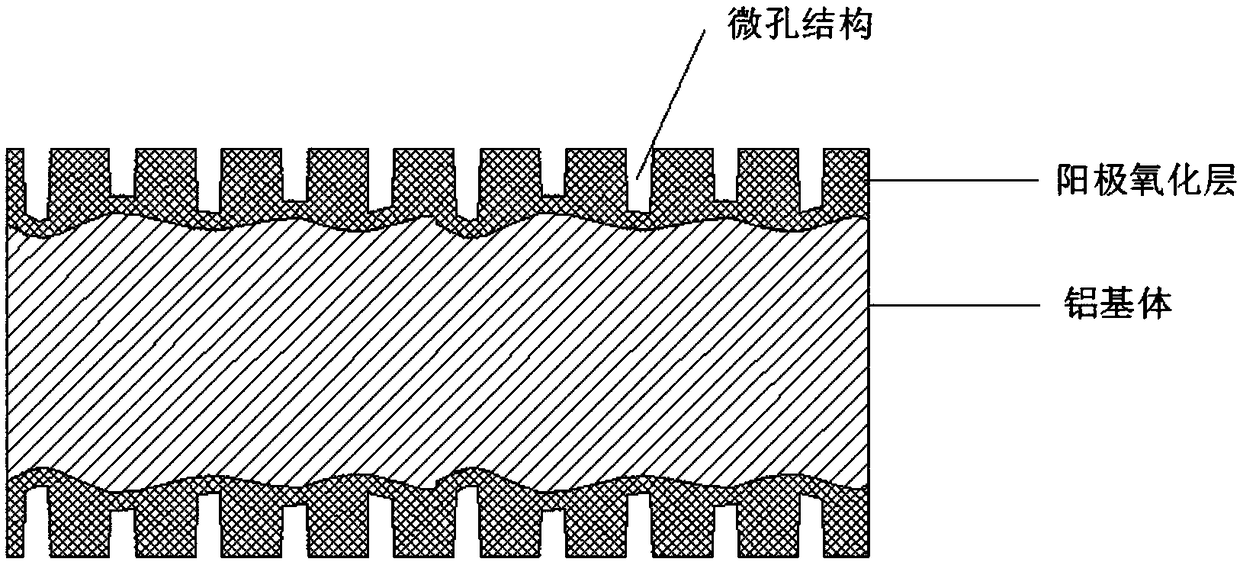

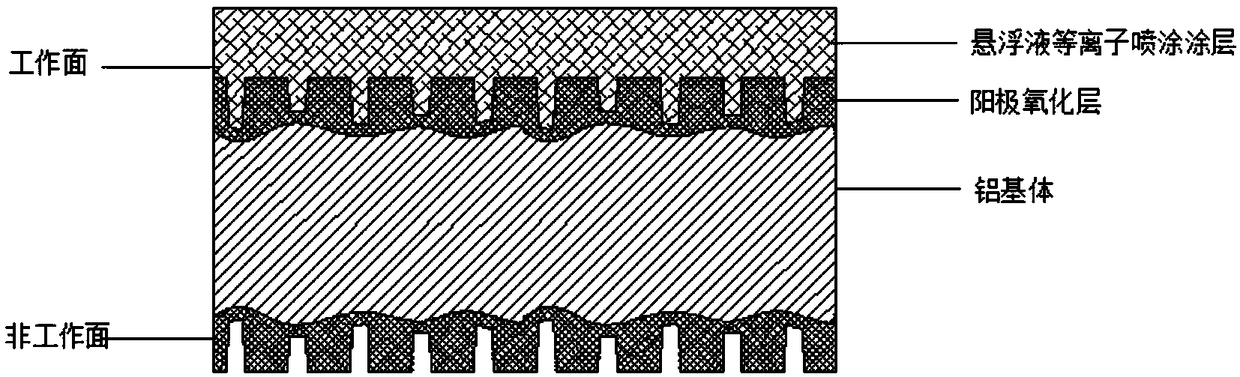

[0035] Step 5: Anodizing: use mixed acid of oxalic acid and sulfuric acid or oxalic acid to anodize aluminum parts, the acid con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com