Copper recovery and regeneration system for acidic copper(II) chloride etchant and recovery and regeneration method

A regeneration system and etching solution technology, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve the problems of large consumption of chemical agents, waste of chemical raw materials, and complicated equipment, so as to improve the efficiency of copper recovery, save production costs, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

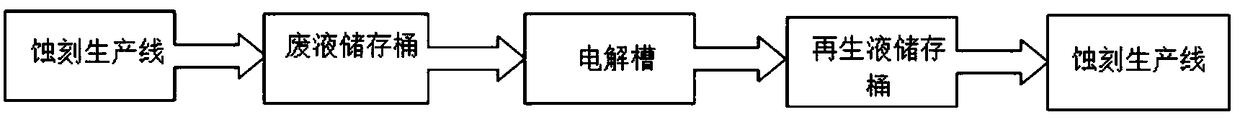

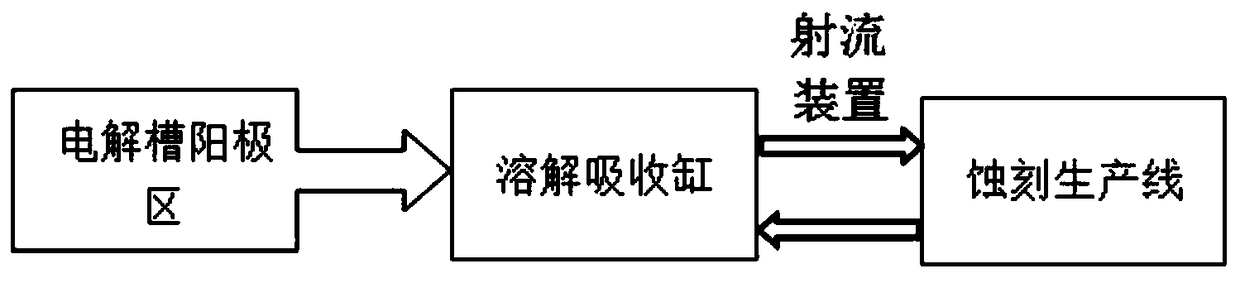

[0045] The acidic copper chloride etching solution copper recovery and regeneration system in this embodiment includes an etching solution regeneration system and a waste gas treatment system located downstream of the etching solution regeneration system, and also includes a molten iron washing solution treatment system. The etching solution regeneration system includes an etching production line connected in sequence, a waste Liquid storage barrel, electrolytic cell, regeneration liquid storage barrel, the downstream of the regeneration liquid storage barrel is connected to the etching production line, the anode area of the electrolytic cell is connected to the dissolution absorption cylinder, the jet device, and the etching production line are connected in sequence;

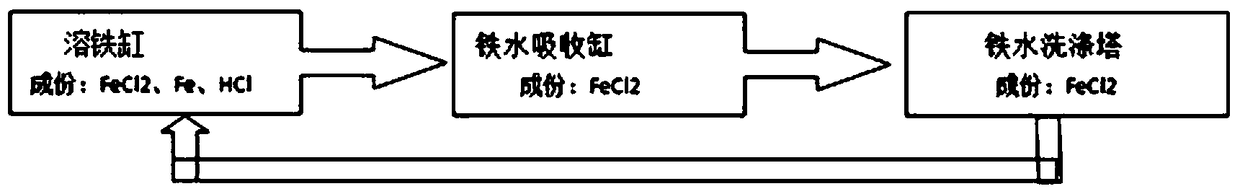

[0046] The molten iron washing liquid treatment system includes a molten iron tank, a molten iron absorption tank, and a molten iron washing tower connected in sequence;

[0047] The etching production line ha...

Embodiment 2

[0053] The acidic copper chloride etching solution copper recovery and regeneration system in this embodiment includes an etching solution regeneration system and a waste gas treatment system located downstream of the etching solution regeneration system, and also includes a molten iron washing solution treatment system. The etching solution regeneration system includes an etching production line connected in sequence, a waste Liquid storage barrel, electrolytic cell, regeneration liquid storage barrel, the downstream of the regeneration liquid storage barrel is connected to the etching production line, the anode area of the electrolytic cell is connected to the dissolution absorption cylinder, the jet device, and the etching production line are connected in sequence;

[0054] The molten iron washing liquid treatment system includes a molten iron tank, a molten iron absorption tank, and a molten iron washing tower connected in sequence;

[0055] The etching production line ha...

Embodiment 3

[0062] The acidic copper chloride etching solution copper recovery and regeneration system in this embodiment includes an etching solution regeneration system and a waste gas treatment system located downstream of the etching solution regeneration system, and also includes a molten iron washing solution treatment system. The etching solution regeneration system includes an etching production line connected in sequence, a waste Liquid storage barrel, electrolytic cell, regeneration liquid storage barrel, the downstream of the regeneration liquid storage barrel is connected to the etching production line, the anode area of the electrolytic cell is connected to the dissolution absorption cylinder, the jet device, and the etching production line are connected in sequence;

[0063] The molten iron washing liquid treatment system includes a molten iron tank, a molten iron absorption tank, and a molten iron washing tower connected in sequence;

[0064] The etching production line ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com