A samarium cobalt material with high knee coercivity and a preparation method thereof

A technology of coercive force and samarium cobalt, applied in the direction of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., to achieve the effects of stabilizing the production process, reducing segregation, and improving anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

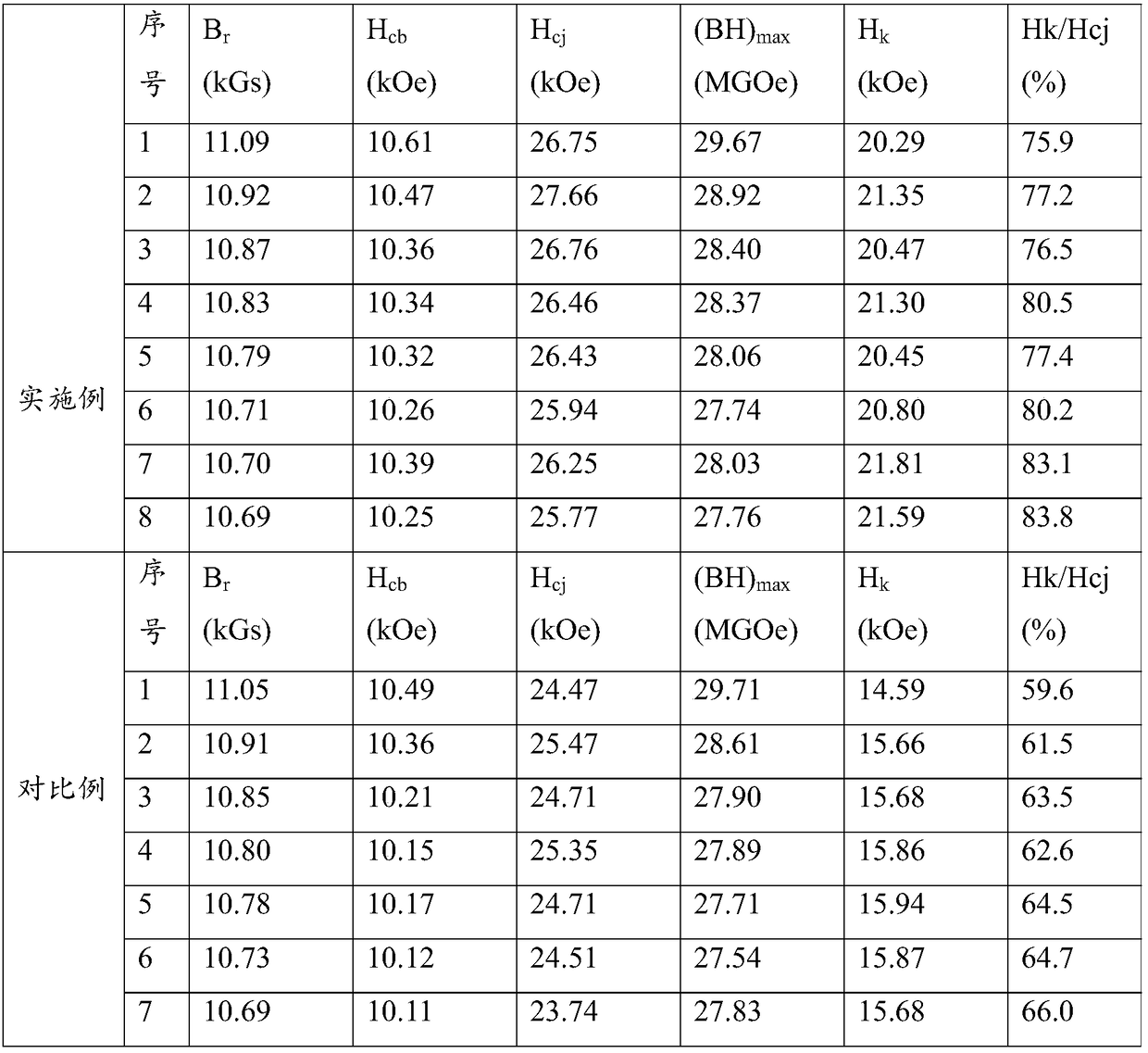

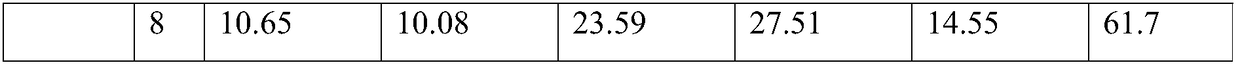

Examples

Embodiment 1

[0025] In this embodiment, the raw materials are calculated in parts by weight, Sm 25.5g; Co 48g; Cu 4.5g; Zr 2.5g; Nb 0.2g; Fe15.6g.

[0026] The specific preparation process is as follows:

[0027] Melting: Put the raw materials into the vacuum melting furnace in the order of Fe-Cu-Co-Zr-Nb-Sm, evacuate to 0.10Pa or below, fill with inert gas to make the vacuum degree -0.06MPa, increase the melting power to melt the raw materials , The raw materials are all melted, and after the refining is continued for 2-10 minutes, the alloy melt is obtained.

[0028] Ingot casting: Pour the molten liquid into a copper plate condensation mold with a width of 25mm and a 15°C circulating water for cooling.

[0029] Pulverizing: After the ingot is first broken and middle broken, it enters the jet mill for pulverization, and the oxygen content in the jet mill <200ppm, the grinding pressure is 0.4MPa, and the particle size of the obtained powder SMD is 5.0μm.

[0030] Molding: Use automatic press moldi...

Embodiment 2

[0033] In this embodiment, the raw materials are calculated in parts by weight, Sm 26g; Co 49g; Cu 5.5g; Zr 2.8g; Nb0.03g; Fe15.6g.

[0034] The specific preparation process is as follows:

[0035] Melting: the raw materials are added to the vacuum melting furnace in the order of Fe-Cu-Co-Zr-Nb-Sm, vacuumed to 0.08Pa or below, filled with inert gas to make the vacuum degree -0.06MPa, increase the melting power to melt the raw materials, All the raw materials are melted, and after the refining is continued for 2-10 minutes, an alloy melt is obtained.

[0036] Ingot casting: Pour the molten liquid into a copper plate condensation mold with a width of 25mm and a 10°C circulating water for cooling.

[0037] Pulverizing: After the ingot is first broken and middle broken, it enters the jet mill for pulverization, and the oxygen content in the jet mill <200ppm, the grinding pressure is 0.5MPa, and the particle size of the obtained powder is 3.4μm.

[0038] Forming: Use full-automatic press fo...

Embodiment 3

[0041] In this embodiment, the raw materials are calculated in parts by weight, Sm 25g; Co51g; Cu 5g; Zr 3.0g; Nb 0.25g; Fe17.5g.

[0042] The specific preparation process is as follows:

[0043] Melting: the raw materials are added to the vacuum melting furnace in the order of Fe-Cu-Co-Zr-Nb-Sm, vacuumed to 0.08Pa or below, filled with inert gas to make the vacuum degree -0.06MPa, increase the melting power to melt the raw materials, All the raw materials are melted, and after the refining is continued for 2-10 minutes, an alloy melt is obtained.

[0044] Ingot casting: Pour the molten liquid into a carbon steel condensation mold with a width of 25mm and a 15°C circulating water for cooling.

[0045] Pulverizing: After the ingot is first broken and middle broken, it enters the jet mill for pulverization, and the oxygen content in the jet mill <200ppm, the grinding pressure is 0.55MPa, and the particle size of the obtained powder is 4.6μm.

[0046] Molding: Use automatic press molding,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com