A method for preparing a sulfur-based cathode material by using reticulated porous nano-lanthanum oxide

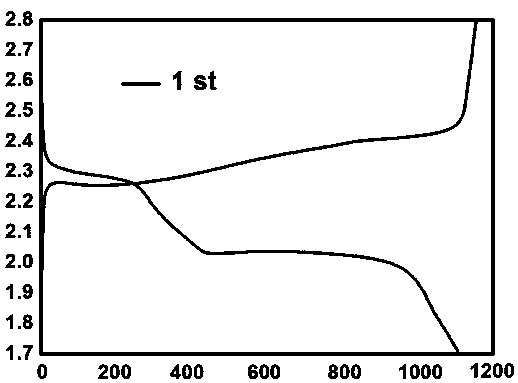

A technology of nano-lanthanum oxide and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as low electron and ion transmission efficiency, shortened cycle life of lithium-sulfur batteries, and damage to the physical structure of electrodes, achieving spray drying and Easy hydrothermal strategy, excellent cycle stability, effect of shortening the transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

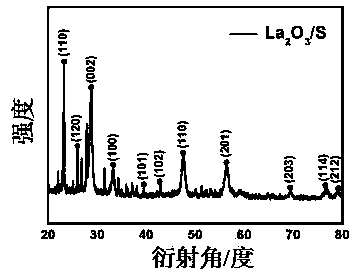

[0025] The first step, the preparation of porous network nano-lanthanum oxide:

[0026] Mix 0.1 mol / L lanthanum nitrate and 0.9 mol / L urea at a volume ratio of 1:1, and then ultrasonically disperse the mixed solution for 3 h at 500 power using an ultrasonic cell pulverizer. The obtained homogeneous mixed solution was spray-dried. During spray drying, the temperature was kept at 400° C., the air flow rate was kept at 8 cc / min, the feed rate was 0.5 ml / min, and the needle passing rate was 1 time / 5 seconds. Since lanthanum nitrate and urea react chemically at 400°C to generate lanthanum oxide, nitrogen, carbon dioxide and water vapor, pure porous network nano-lanthanum oxide will be obtained after spray drying.

[0027] The second step, the preparation of porous network nano-lanthanum oxide / sulfur cathode material:

[0028] Weigh the required lanthanum oxide and nano-sulfur according to the mass ratio of 1:2, place the mixture in a mortar and grind it into a uniform fine powder...

Embodiment 2

[0033] The first step, the preparation of porous network nano-lanthanum oxide:

[0034] Mix 0.1 mol / L lanthanum nitrate and 0.9 mol / L urea at a volume ratio of 1:1, and then ultrasonically disperse the mixed solution at 600 power for 4 hours using an ultrasonic cell pulverizer. The obtained homogeneous mixed solution was spray-dried. During spray drying, the temperature was kept at 400° C., the air flow rate was kept at 10 cc / min, the feed rate was 1 ml / min, and the needle passing rate was 1 time / 8 seconds. Since lanthanum nitrate and urea react chemically at 400°C to generate lanthanum oxide, nitrogen, carbon dioxide and water vapor, pure porous network nano-lanthanum oxide will be obtained after spray drying.

[0035] The second step, the preparation of porous network nano-lanthanum oxide / sulfur cathode material:

[0036]Weigh the required lanthanum oxide and nano-sulfur according to the mass ratio of 1:4, place the mixture in a mortar and grind it into a uniform fine powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com