A method for preparing sulfur-based positive electrode materials using mesh-like porous nano-lanthanum oxide

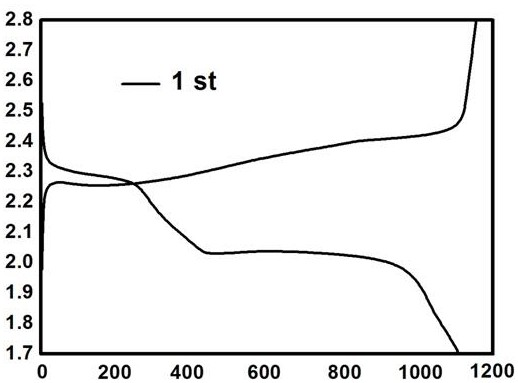

A technology of nano-lanthanum oxide and positive electrode materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of low electron and ion transmission efficiency, shortened cycle life of lithium-sulfur batteries, and damage to the physical structure of electrodes, etc., to achieve spray drying Easy and hydrothermal strategy, excellent cycle stability, effect of shortening the transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The first step, the preparation of porous network nano-lanthanum oxide:

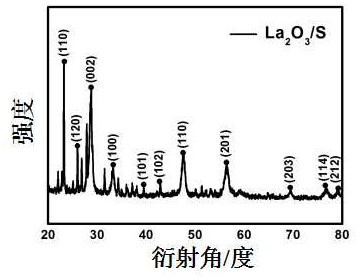

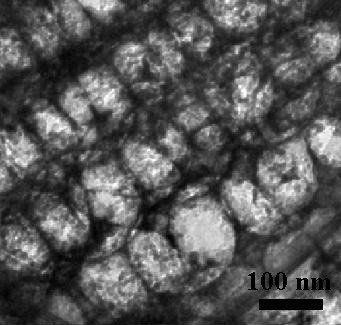

[0026] Mix 0.1 mol / L lanthanum nitrate and 0.9 mol / L urea at a volume ratio of 1:1, and then ultrasonically disperse the mixed solution for 3 h at 500 power using an ultrasonic cell pulverizer. The obtained homogeneous mixed solution was spray-dried. During spray drying, the temperature was kept at 400° C., the air flow rate was kept at 8 cc / min, the feed rate was 0.5 ml / min, and the needle passing rate was 1 time / 5 seconds. Since lanthanum nitrate and urea react chemically at 400°C to generate lanthanum oxide, nitrogen, carbon dioxide and water vapor, pure porous network nano-lanthanum oxide will be obtained after spray drying.

[0027] The second step, the preparation of porous network nano-lanthanum oxide / sulfur cathode material:

[0028] Weigh the required lanthanum oxide and nano-sulfur according to the mass ratio of 1:2, place the mixture in a mortar and grind it into a uniform fine powder...

Embodiment 2

[0033] The first step, the preparation of porous network nano-lanthanum oxide:

[0034] Mix 0.1 mol / L lanthanum nitrate and 0.9 mol / L urea at a volume ratio of 1:1, and then ultrasonically disperse the mixed solution at 600 power for 4 hours using an ultrasonic cell pulverizer. The obtained homogeneous mixed solution was spray-dried. During spray drying, the temperature was kept at 400° C., the air flow rate was kept at 10 cc / min, the feed rate was 1 ml / min, and the needle passing rate was 1 time / 8 seconds. Since lanthanum nitrate and urea react chemically at 400°C to generate lanthanum oxide, nitrogen, carbon dioxide and water vapor, pure porous network nano-lanthanum oxide will be obtained after spray drying.

[0035] The second step, the preparation of porous network nano-lanthanum oxide / sulfur cathode material:

[0036]Weigh the required lanthanum oxide and nano-sulfur according to the mass ratio of 1:4, place the mixture in a mortar and grind it into a uniform fine powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com