Selenium-enriched orange peel probiotics product

A technology of probiotics and orange peel, applied in dairy products, food ingredients, milk preparations, etc., can solve the problems of loss of functional components of mulberry fruit, oxidation damage of water-soluble pigments, etc., to inhibit the growth of yeast, product safety, enhance The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

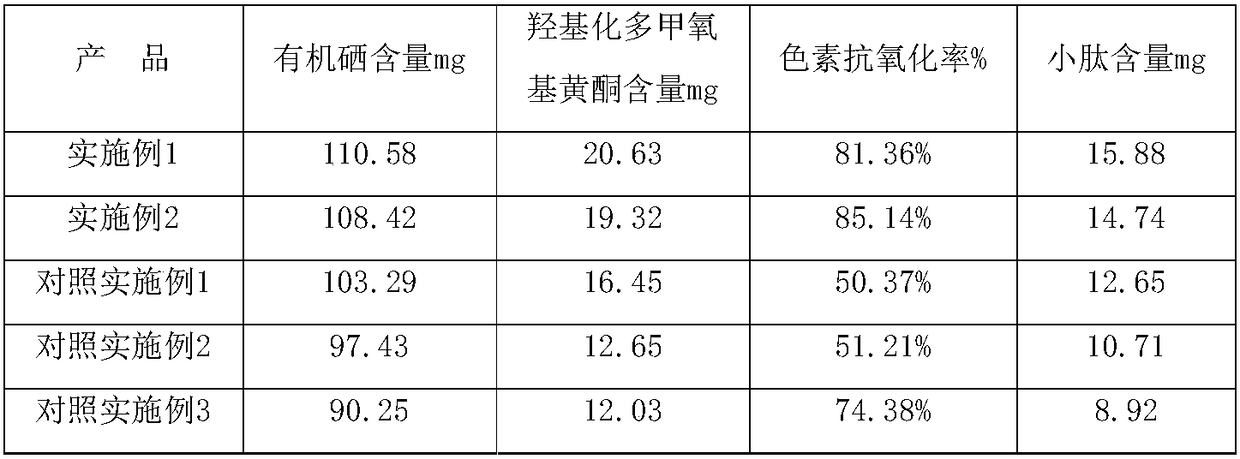

Examples

Embodiment 1

[0027] Take 50kg of orange peel, add 1.5kg of soybean meal cake and pulverize it, add 4kg of flour, add 120kg of water, add 57000U glucoamylase for saccharification for 4 hours, then add 250g of sodium selenite and 300g of zinc oxide powder, inoculate 12L of baker's yeast after high temperature sterilization , aerobic fermentation at 28°C for 3 days, centrifuged at 5000rpm for 40min to obtain supernatant and 52.62kg of precipitate; add 55L of water to the precipitate, then add 20000U neutral protease and 300g of calcium chloride, keep at 35°C for 4h, then add crushed mulberry 50kg of fruit powder, stirred for 60 minutes, filtered to obtain filtrate I and pomace I; after high-temperature sterilization of pomace I, supernatant was added, aerobic fermentation at 28°C for 40 hours, and filtrate II was obtained by filtration; after high-temperature sterilization of 150L milk, Add 20L of lactic acid bacteria and 15L of bifidobacteria to ferment for 40h, then mix and stir with filtrat...

Embodiment 2

[0029] Take 100kg of orange peel and add 3kg of soybean meal cake to crush it, add 10kg of flour, add 250kg of water, add 180000U glucoamylase for saccharification for 5 hours, then add 500g of sodium selenite and 500g of zinc oxide powder, inoculate 30L of baker's yeast after high temperature sterilization, Aerobic fermentation at 28°C for 3 days, centrifuged at 5000rpm for 40min to obtain supernatant and 104.57kg of precipitate; add 110L of water to the precipitate, then add 50000U neutral protease and 450g of calcium chloride, keep warm at 35°C for 4h, then add crushed mulberry fruit powder 120kg, stirred for 50 minutes, filtered to obtain filtrate Ⅰ and pomace Ⅰ; after high-temperature sterilization of pomace Ⅰ, supernatant was added, aerobic fermentation at 28°C for 40 hours, and filtrate Ⅱ was obtained by filtration; after 200L milk was subjected to high-temperature sterilization, added 35L of lactic acid bacteria and 25L of bifidobacteria were fermented for 40 hours, the...

Embodiment 1

[0031] Take 50kg of orange peel, add 1.5kg of soybean meal cake and pulverize it, add 4kg of flour, add 120kg of water, add 57000U glucoamylase for saccharification for 4 hours, then add 250g of sodium selenite and 300g of zinc oxide powder, add 50kg of crushed mulberry fruit powder, and heat After sterilization, inoculate 12L baker’s yeast, ferment aerobically at 28°C for 3 days, centrifuge at 5000rpm for 40min to obtain supernatant and precipitate; add 50L water to the precipitate, then add 20000U neutral protease and 300g calcium chloride, and incubate at 35°C for 5h. Filtrate I and pomace I were obtained by filtration; after high-temperature sterilization of 150L of milk, 20L of lactic acid bacteria and 15L of bifidobacteria were added to ferment for 40 hours, then mixed with filtrate I at 13°C for 3 hours, and then stored at 4°C after mixing evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com