A method for assisted synthesis of molecular sieves by ultraviolet radiation

A molecular sieve and ultraviolet light technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of special reaction, difficult to control, unfavorable energy saving and emission reduction, and achieve the effect of reducing alkalinity and reducing synthesis cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example provides the preparation method of A-type molecular sieve synthesis at room temperature under ultraviolet radiation:

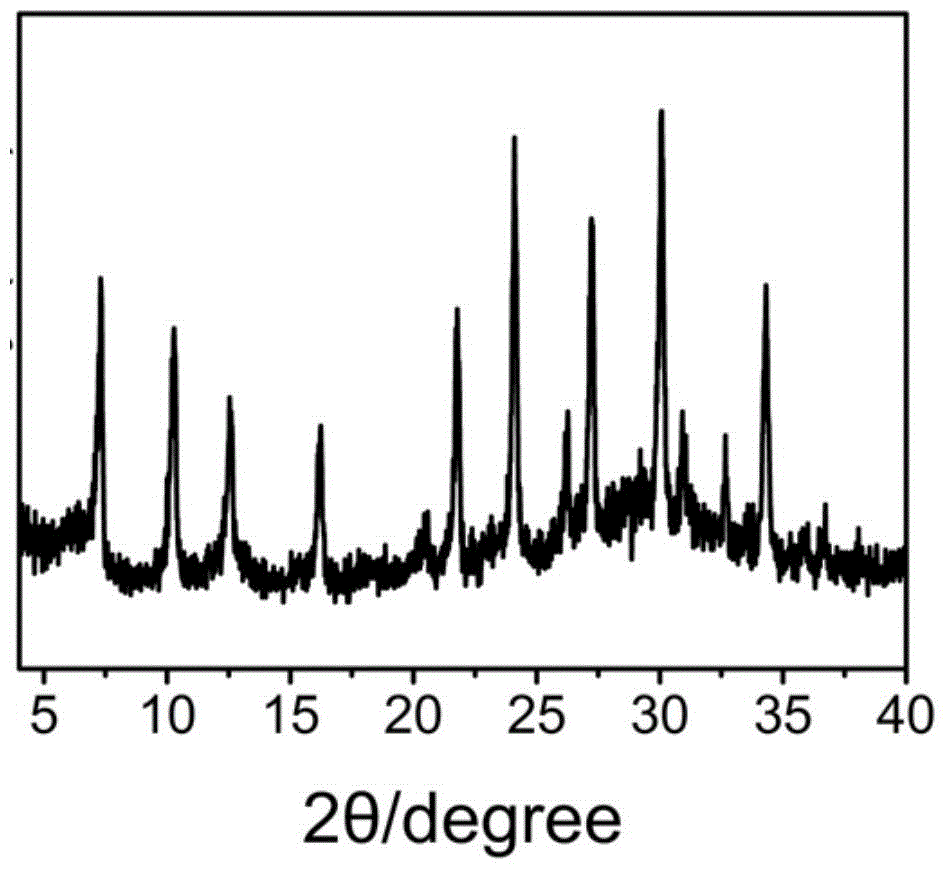

[0032]Take 36.66g of sodium silicate nonahydrate, mix with 14g of sodium hydroxide and 60g of deionized water and add it into a beaker, stir it evenly with a mixer at 300 rpm, and heat it properly to make it a clear solution A. Mix 15g of metaaluminate Sodium, 14g sodium hydroxide and 60g deionized water are mixed together and added to the beaker, stirred evenly with a mixer at 300 rpm, and can be properly heated to make it into a clear solution B, and the B solution is added dropwise to the A solution at 20mL / min In , a white initial gel is obtained, and the molar ratio of the initial gel is SiO 2 :Al 2 o 3 :H 2 O: Na 2 O is 1:0.47:60.70:4.18, kept stirring at 500 rpm for 2 hours, transferred it to a quartz container, and adjusted the distance between the UV light and the quartz container so that the UV light density was 40w / m 2 Radia...

Embodiment 2

[0036] This example provides a method for synthesizing type A molecular sieve at room temperature under ultraviolet radiation and effectively reducing the reaction alkalinity:

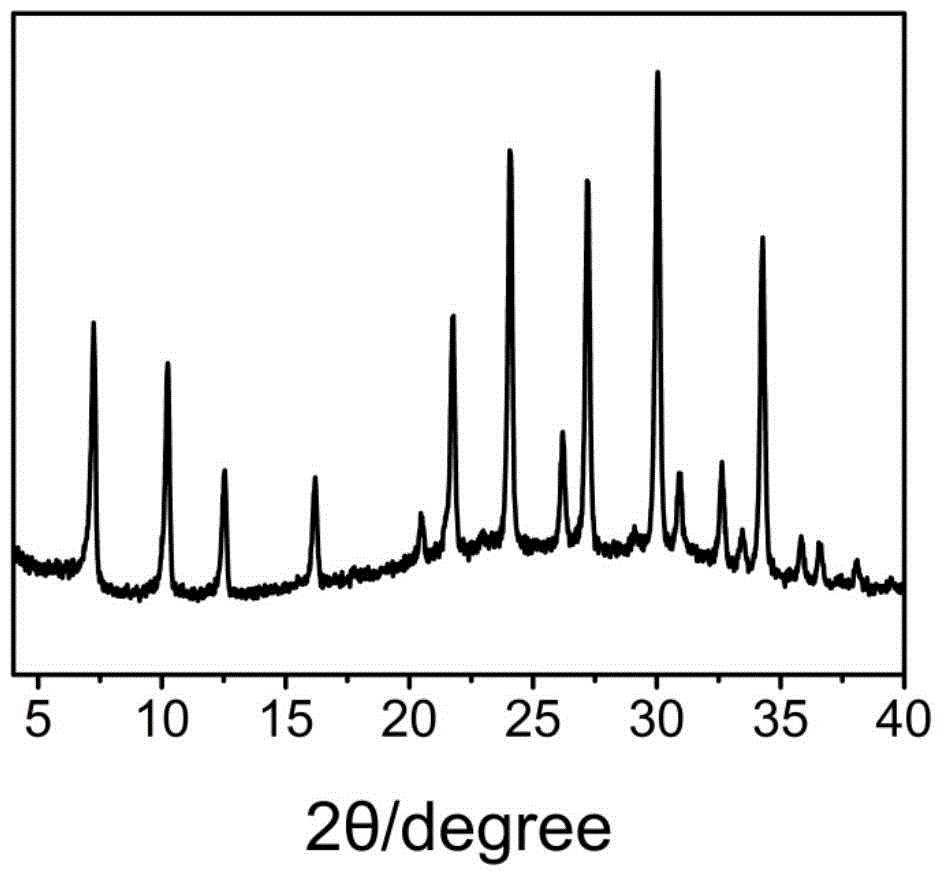

[0037] Mix 36.66g sodium silicate nonahydrate, 7g sodium hydroxide and 60g deionized water into a beaker, stir evenly with a mixer at 300 rpm, heat it properly to make it a clear solution A, and mix 15g metaaluminate Sodium, 7g sodium hydroxide and 60g deionized water are mixed together and added to the beaker, stirred evenly with a mixer at 300 rpm, and can be properly heated to make it into a clear solution B, and the B solution is added dropwise to the A solution at 20mL / min In , a white initial gel is obtained, and the molar ratio of the initial gel is SiO 2 :Al 2 o 3 :H 2 O: Na 2 O is 1:0.47:60.70:2.82, kept stirring at 500 rpm for 2 hours, transferred it to a quartz container, and adjusted the distance between the UV light and the quartz container so that the UV light density was 40w / m 2 Rad...

Embodiment 3

[0039] This example gives the preparation method for synthesis of type A molecular sieve at 40°C under ultraviolet radiation:

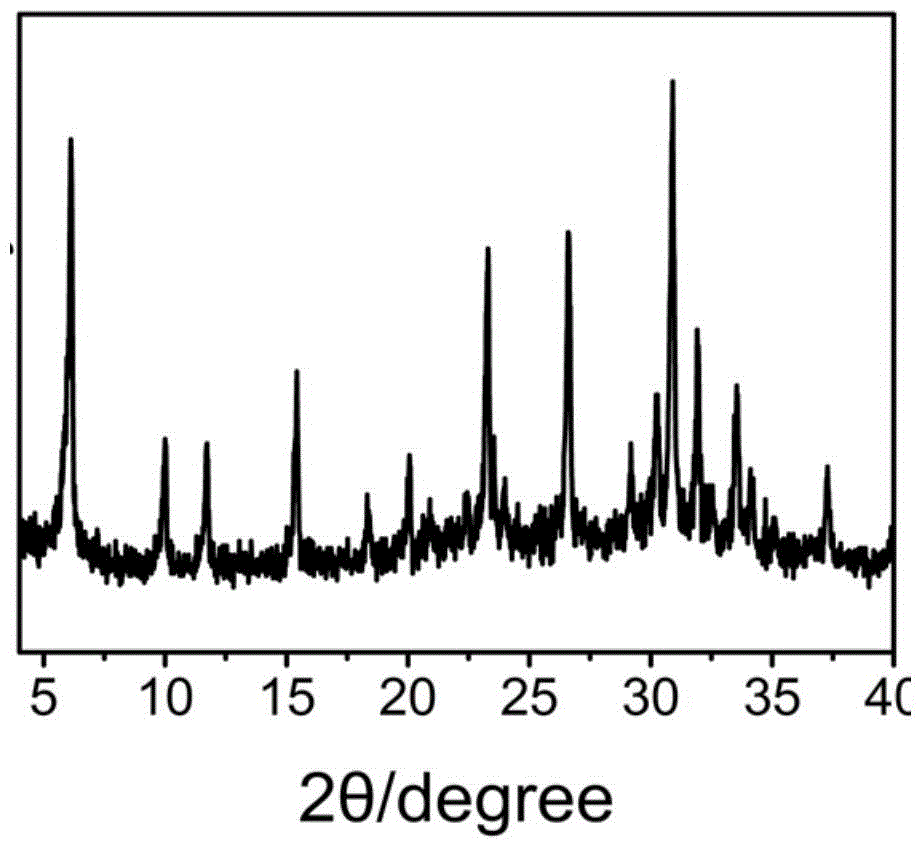

[0040] Take 2.143g of sodium silicate pentahydrate, mix with 3g of sodium hydroxide and 17.73g of deionized water and add it into a beaker, stir evenly with a mixer at 300 rpm to make it a clear solution A, and mix 0.891g of sodium metaaluminate Mix it with 3g sodium hydroxide and 18.26g deionized water and add it to the beaker, stir evenly with a mixer at 300 rpm, heat it properly to make it a clear solution B, and add solution B dropwise to solution A at 20mL / min In , a white initial gel is obtained, and the molar ratio of the initial gel is SiO 2 :Al 2 o 3 :H 2 O: Na 2 O is 1:0.47:200:15, kept stirring at 500 rpm for 2 hours, transferred it to a quartz container, and adjusted the distance between the UV light and the quartz container so that the UV light density was 40w / m 2 Radiation onto the initial gel, crystallization at 40°C for 8 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com