Plant extraction and purification process

A plant extraction and process technology, applied in the direction of sugar derivatives, sugar derivatives, organic chemistry, etc., can solve problems such as bitter taste of plant extracts, can not remove the bitter taste well, and achieve environmental friendliness and product safety , the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

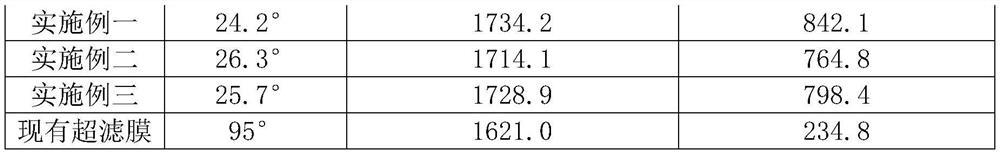

Examples

Embodiment 1

[0031] Preparation of modified nano titanium dioxide

[0032] Stir and mix 2ml of 3-aminopropyltriethoxysilane and 100ml of absolute ethanol evenly, add 12g of nano-titanium dioxide, stir and react for 20h under airtight conditions, after the completion of the reaction, vacuum dry and grind, then ultrasonically disperse in a volume fraction of 50ml In a 2% glutaraldehyde solution, keep stirring and reacting for 22 hours under airtight conditions, filter and dry, add 100ml 2wt% sulfonated chitosan solution, stir and react at a stirring speed of 800r / min for 3 hours, and the reaction is completed. Filter and dry to obtain modified nano titanium dioxide.

[0033] Preparation of Modified Polyvinyl Alcohol

[0034] Add polyvinyl alcohol to 50ml of 20mM phosphate buffered saline solution, magnetically stir until completely dissolved to obtain a 5mg / mL polyvinyl alcohol solution, add 1.93g of N-hydroxysuccinimide, and continue stirring for 30min under a nitrogen atmosphere, add 2.5...

Embodiment 2

[0047] Preparation of modified nano titanium dioxide

[0048] Stir and mix 2ml of 3-aminopropyltriethoxysilane and 100ml of absolute ethanol evenly, add 15g of nano-titanium dioxide, stir and react for 21h under airtight conditions, after the reaction is completed, vacuum dry, grind, and ultrasonically disperse in a volume fraction of 50ml In a 2% glutaraldehyde solution, keep stirring and reacting for 20h under airtight conditions, filter and dry, add 100ml 2wt% sulfonated chitosan solution, stir and react at a stirring speed of 800r / min for 4h, and the reaction is completed. Filter and dry to obtain modified nano titanium dioxide.

[0049] Preparation of Modified Polyvinyl Alcohol

[0050] Add polyvinyl alcohol to 50ml of 20mM phosphate buffered saline solution, magnetically stir until completely dissolved to obtain a 6mg / mL polyvinyl alcohol solution, add 1.61g of N-hydroxysuccinimide, continue stirring for 30min under a nitrogen atmosphere, add 2.37g dopamine hydrochlori...

Embodiment 3

[0062] Preparation of modified nano titanium dioxide

[0063] Stir and mix 2ml of 3-aminopropyltriethoxysilane and 100ml of absolute ethanol evenly, add 10g of nano-titanium dioxide, stir and react under airtight conditions for 18h, after the reaction is completed, vacuum dry and grind, then ultrasonically disperse in a volume fraction of 50ml In a 2% glutaraldehyde solution, keep stirring and reacting for 21 hours under airtight conditions, add 100ml of 2wt% sulfonated chitosan solution after filtering and drying, stir and react at a stirring speed of 800r / min for 3 hours, and the reaction is completed. Filter and dry to obtain modified nano titanium dioxide.

[0064] Preparation of Modified Polyvinyl Alcohol

[0065] Add polyvinyl alcohol to 50ml of 20mM phosphate buffered saline solution, magnetically stir until completely dissolved to obtain 8mg / mL polyvinyl alcohol solution, add 1.79g of N-hydroxysuccinimide, continue stirring for 30min under nitrogen atmosphere, add 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com