Device for degrading high-concentration petroleum emissions

A high-concentration, high-efficiency emission technology, applied in gas treatment, membrane technology, and separation of dispersed particles, can solve problems such as poor operational safety, complex process, and high operating cost, and achieve efficient and stable operation, high biophase concentration, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

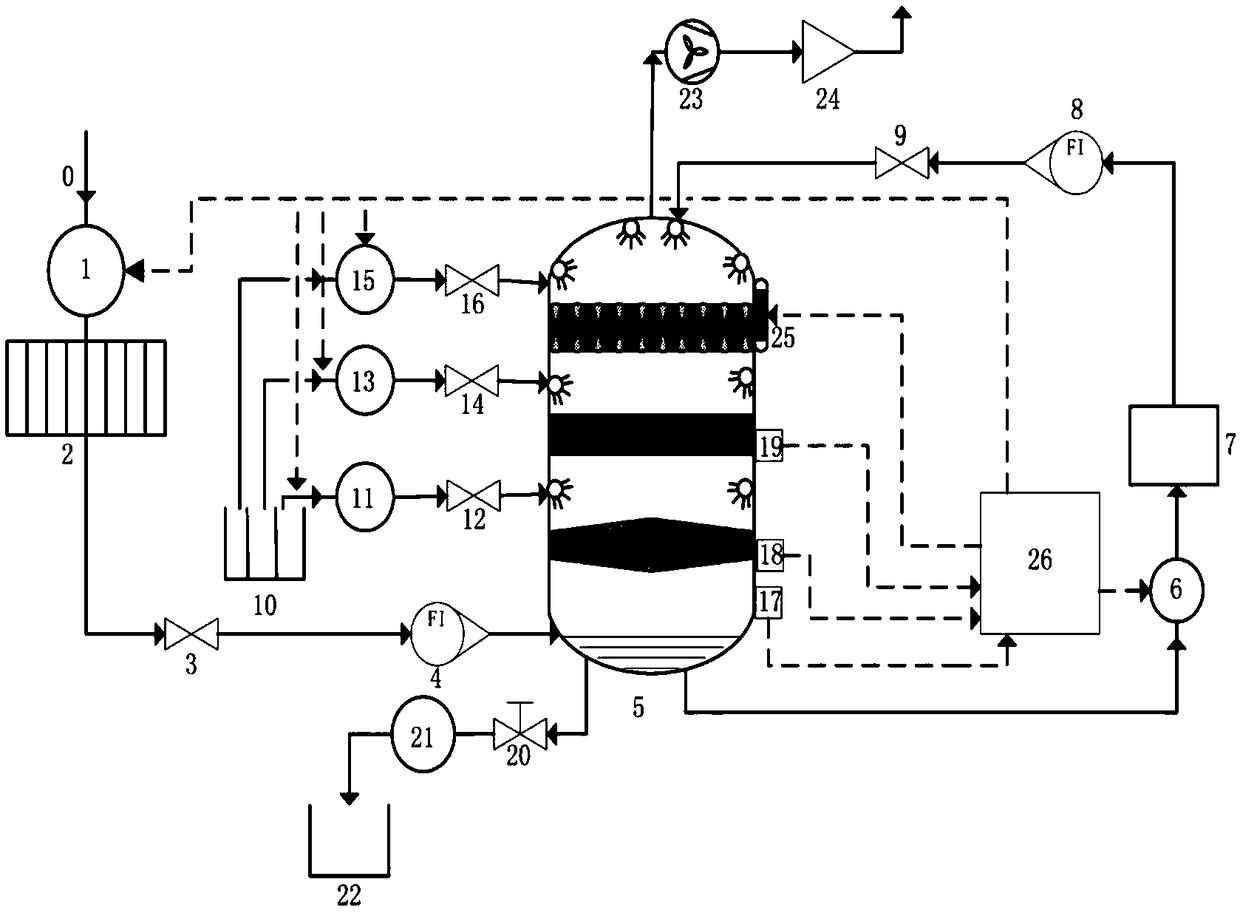

[0026] Such as figure 1 As shown, the device for purifying high-concentration organic waste gas according to the present invention mainly includes an air inlet 0, an air intake pump 1 connected to the air inlet 0, an activated carbon filter 2 connected to the air intake pump 1, and the activated carbon The filter 2 is used to connect with the first solenoid valve 3 , the first solenoid valve 3 is connected with the first rotameter 4 , and the first rotameter 4 is connected with the biological trickling filter 5 .

[0027] Further, the device also includes a circulating water pump 6, the circulating water pump 6 is connected to a circulating liquid tank 7, the circulating liquid tank 7 is connected to a second rotameter 8, and the second rotameter 8 is connected to a first Two solenoid valves 9, the second solenoid valve 9 is connected to the biological trickling filter 5.

[0028]Further, the device also includes a nutrient solution tank 10, which is divided into three indepe...

Embodiment 2

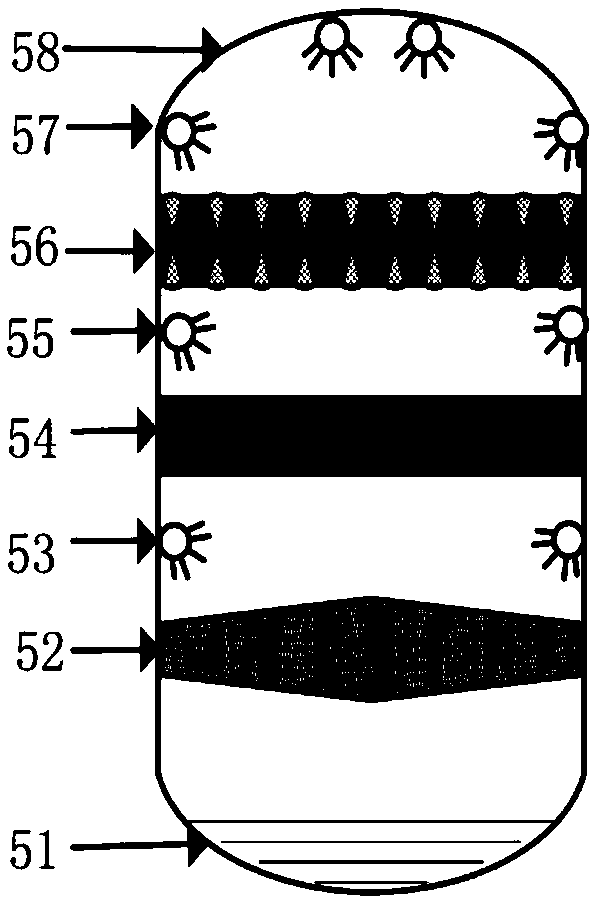

[0031] The biodegradation process of petroleum compounds includes three processes. First, petroleum compounds are adsorbed to the surface of microorganisms; secondly, petroleum compounds are transferred to microbial cell membranes through reactions; and then these compounds are degraded in microbial cytoplasm through microbial basic metabolic pathways. Because petroleum compounds will present different molecular structures during the discharge process, such as saturated hydrocarbons, alkanes, polycyclic aromatic hydrocarbons, etc., different bacteria, fungi, and algae have different metabolic pathways, that is, degradation pathways. Therefore, providing multiple biological filtration layers is helpful to realize the one-time removal of multiple pollutants.

[0032] The main filter medium of the first biofiltration layer is the bacterial biofilm of the bacterial substrate, and the preparation method of the biofilm is as follows: take adjacent oligotrophic bacteria (Abiotrophia a...

Embodiment 3

[0038] The main filter medium of the second biofiltration layer 54 is the fungal biofilm of the fungal substrate, and the preparation method of the fungal biofilm is as follows: take Aspergillus giganteus, Aspergillus gliocladium, Mucor pusillus), Cryptococcus Kutzing, Candida pelliculosa, Ceotruchum candidum, and Cryytococcus neoformans. The preserved strains of the above strains are cultured on the fungal culture medium by streaking inoculation, cultured at 28°C for 24 hours to rejuvenate the strains and form a single colony, and after expanding the culture of the single strain, the culture solution of the single strain is centrifuged Concentrate, mix the concentrated solution according to the following weight percentages to make a mixture of fungal strains: 18% Aspergillus gigantum, 13% Aspergillus colloidus, 17% Mucor micromyces, 15% Cryptococcus genus, and 19% Pymphaea candida , Candida 11%, and Geotrichum candidum 7%, the strain mixture is attached to the nano-clay light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com