One-dimensional basic cobalt carbonate@two-dimensional CoSe/NF heterostructure composite material and preparation method and application thereof

A technology of heterostructures and composite materials, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of poor electrocatalytic activity and cycle instability, and achieve low cost and stable cycle. Good sex, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

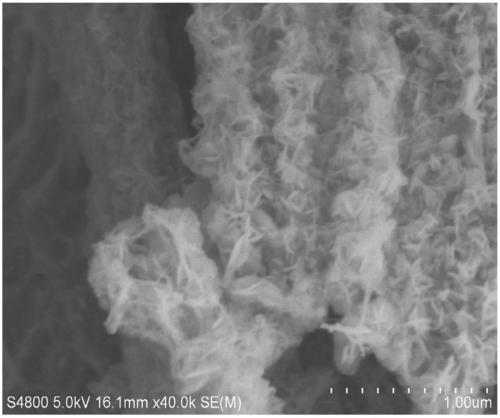

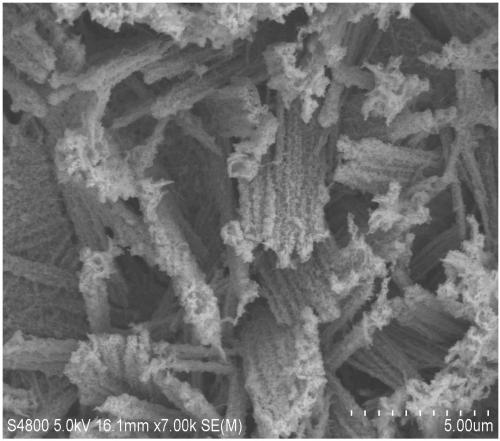

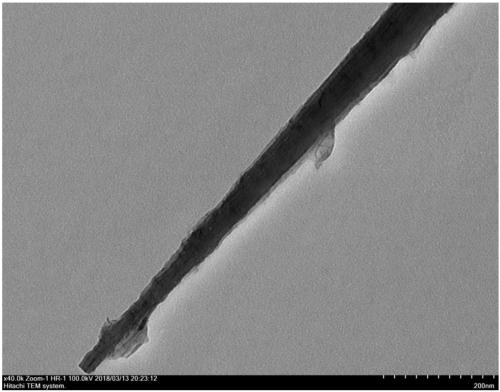

[0021] The invention provides a preparation method of one-dimensional basic cobalt carbonate@two-dimensional CoSe / NF heterostructure composite material, comprising: basic cobalt carbonate nanowire Co(CO 3 ) 0.5 (OH)·0.11H 2 O, selenium source, and cobalt are derived from solvents for solvothermal reaction to prepare one-dimensional basic cobalt carbonate@two-dimensional CoSe / NF heterostructure composites; wherein, basic cobalt carbonate nanowires are supported on foamed nickel NF.

[0022] In the above preparation method, the amount of each material can be selected in a wide range, but in order to further improve the electrocatalytic performance and cycle performance of the heterostructure composite material, preferably, basic cobalt carbonate nanowires, selenium source, cobalt source , The dosage ratio of NF is 0.02-0.08g:0.5-2.5mmol:0.5-2.5mmol:2.4-4mmol.

[0023] In the above preparation method, the amount of solvent can be selected in a wide range, but in order to furthe...

Embodiment 1

[0035] 1) Dissolve 1mmol of cobalt nitrate hexahydrate, 3mmol of ammonium fluoride, and 10mmol of urea in 35ml of deionized water. After magnetically stirring for 30min, transfer the mixed solution into a 50ml reaction kettle, and then add 6cm 2 Nickel foam (0.141g, 2.4mmol); put the reaction kettle in a thermostat at 120°C, and react for 10h; after the reaction, wash and dry to obtain one-dimensional Co(CO 3 ) 0.5 (OH)·0.11H 2 O / NF nanowire 0.2626g (containing 0.0446g Co(CO 3 )0.5 (OH)·0.11H 2 O);

[0036] 2) Add the mixed solution of cobalt acetate tetrahydrate and sodium selenium hydride (30ml, containing 1.2mmol each of cobalt acetate tetrahydrate and sodium selenium hydride) into a 50ml reaction kettle, and then add the above-mentioned 0.2626g one-dimensional Co(CO 3 ) 0.5 (OH)·0.11H 2 O / NF nanowires, sealed, put the reaction kettle into a constant temperature drying oven at 180°C for 3 hours, wash after the reaction, and dry at 70°C to obtain one-dimensional and tw...

Embodiment 2

[0038] 1) Dissolve 2mmol of cobalt nitrate hexahydrate, 5mmol of ammonium fluoride, and 5mmol of urea in 35ml of deionized water. After magnetically stirring for 30min, transfer the mixed solution into a 50ml reaction kettle, and then add 6cm 2 Nickel foam (0.141g); place the reactor in a thermostat at 140°C, and react for 10 hours; after the reaction, wash and dry to obtain one-dimensional Co(CO 3 ) 0.5 (OH)·0.11H 2 O / NF nanowire 0.2894g (containing 0.0714g Co(CO 3 ) 0.5 (OH)·0.11H 2 O);

[0039] 2) Add the mixed solution of cobalt acetate tetrahydrate and sodium selenium hydride (30ml, containing 1mmol each of cobalt acetate tetrahydrate and sodium selenium hydride) into a 50ml reaction kettle, and then add the above-mentioned 0.2894g one-dimensional Co(CO 3 ) 0.5 (OH)·0.11H 2 O / NF nanowires, sealed, put the reaction kettle into a constant temperature drying oven at 160°C for 5 hours, wash after the reaction, and dry at 70°C to obtain one-dimensional and two-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com