Preparation of heteroatom-doped carbon material/Ni-MOF composite electrocatalyst

An electrocatalyst and heteroatom technology, which is applied in the field of preparation of heteroatom-doped carbon materials/Ni-MOF composite electrocatalysts, can solve the problems of high price and limited platinum storage capacity, and achieve improved activity, water electrolysis performance, The effect of improving the activity of electrolyzed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

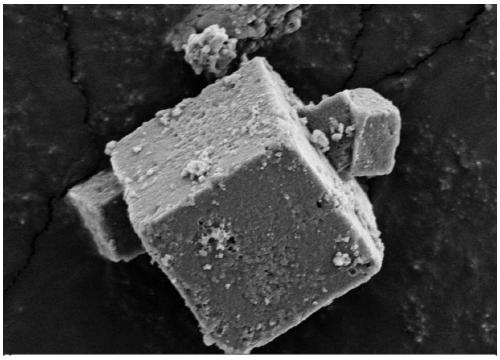

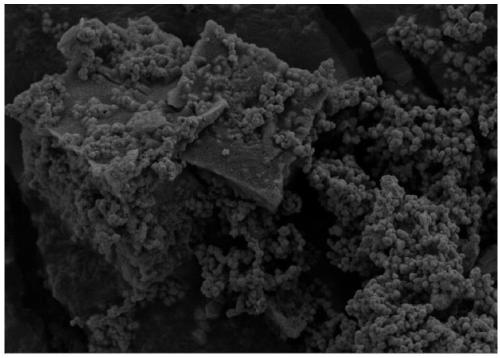

[0012] Embodiment 1: The preparation of a heteroatom-doped carbon material / Ni-MOF composite electrocatalyst of this embodiment is carried out according to the following steps:

[0013] (1) Weigh glucose and thiourea according to a certain molar ratio, add 4.5g of zinc chloride and place it in a beaker, add 16mL of deionized water, stir with a glass rod until dissolved, and place it in a hydrothermal reactor at a certain temperature to react for a certain period of time , ethanol, water repeated suction filtration washing, oven drying at 110°C, and then placed in a tube furnace under an inert atmosphere for carbonization at a certain temperature for a certain period of time to obtain a heteroatom-doped porous carbon material, marked as SNPC;

[0014] (2)C 4 h 6 NiO 4 4H 2 O and trimesic acid (H 3 BTC) was weighed according to a certain molar ratio, adding a certain amount of sulfur and nitrogen doped porous carbon material (SNPC), then adding 32mL DMF and 20mL ethanol, stir...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that in step (1), glucose and thiourea are weighed in a molar ratio of 3:1, hydrothermally reacted at 140°C for 10 hours, and carbonized at 700°C for 2 hours. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step (2), it is weighed according to the molar ratio of 2:1, 5 mg of SNPC is added, and it is hydrothermally reacted at 180° C. for 10 h. Others are the same as those in Embodiment 1 or 2.

[0017] The preparation of a heteroatom-doped carbon material / Ni-MOF composite electrocatalyst is specifically illustrated by the following examples and comparative examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com