Preparation method of diamond/W-Cu composite

A composite material and diamond technology, which is applied in metal material coating technology, metal processing equipment, heating inorganic powder coating, etc., can solve the problems of limited increase in thermal conductivity of composite materials and inability to meet the requirements of heat transfer, etc., to achieve Improve heat transfer performance, low cost, avoid uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

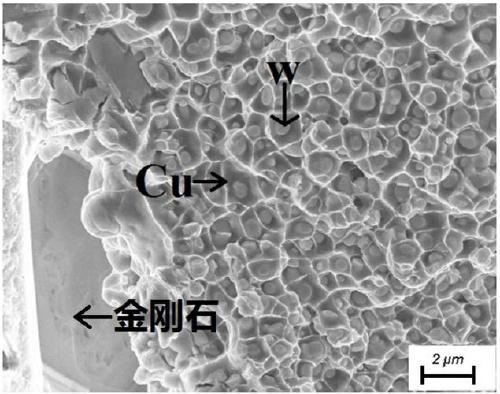

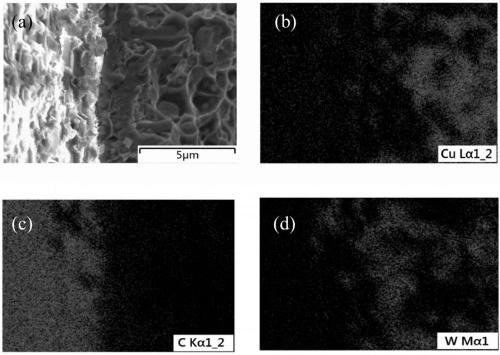

[0027] In this embodiment, a method for preparing a diamond / W-Cu composite material, the specific steps are as follows:

[0028] (1) Put diamond particles and W powder with a mass ratio of 10:1 into the mortar, and add NaCl and BaCl with a mass ratio of 1:10 2 Mix salt, mix evenly (mixed powder of diamond particles and W powder with NaCl and BaCl 2 The mass ratio of mixed salt is 1:1), obtains mixed material; Then mixed material is placed in microwave oven, in N 2 -H 2 Mixed gas (N 2 -H 2 Under the protection of the volume ratio 85:15), by adjusting the power of the microwave oven, heating to 1150°C at a heating rate of 30°C / min and keeping it warm for 20min; after the obtained product is cooled, it is cleaned and dried to obtain W-coated diamond particles on the surface;

[0029] (2) take by weighing 9.8g of copper sulfate (CuSO 4 ·5H 2 O) and 0.02g of 2,2-bipyridine (C 10 h 8 N 2 ), add 250mL deionized water to dissolve to obtain a blue solution; weigh 27g disodium ...

Embodiment 2

[0037] In this embodiment, a method for preparing a diamond / W-Cu composite material, the specific steps are as follows:

[0038] (1) Put diamond particles and W powder with a mass ratio of 10:1 into the mortar, and add NaCl and BaCl with a mass ratio of 1:10 2 Mix salt, mix evenly (mixed powder of diamond particles and W powder with NaCl and BaCl 2 The mass ratio of mixed salt is 1:1), obtains mixed material; Then mixed material is placed in microwave oven, in N 2 -H 2 Mixed gas (N 2 -H 2 Under the protection of the volume ratio 85:15), by adjusting the power of the microwave oven, heating to 1150°C at a heating rate of 30°C / min and keeping it warm for 20min; after the obtained product is cooled, it is cleaned and dried to obtain W-coated diamond particles on the surface;

[0039] (2) take by weighing 9.8g of copper sulfate (CuSO 4 ·5H 2 O) and 0.02g of 2,2-bipyridine (C 10 h 8 N 2 ), add 250mL deionized water to dissolve to obtain a blue solution; weigh 27g disodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com