Online measurement method for welding line characteristic point positions and welding line trajectory automatic measurement system

A technology of welding seam characteristics and measurement methods, which is applied in the field of automatic welding seam trajectory measurement, can solve problems such as the failure of processing methods, and achieve the effect of accurate online automatic welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

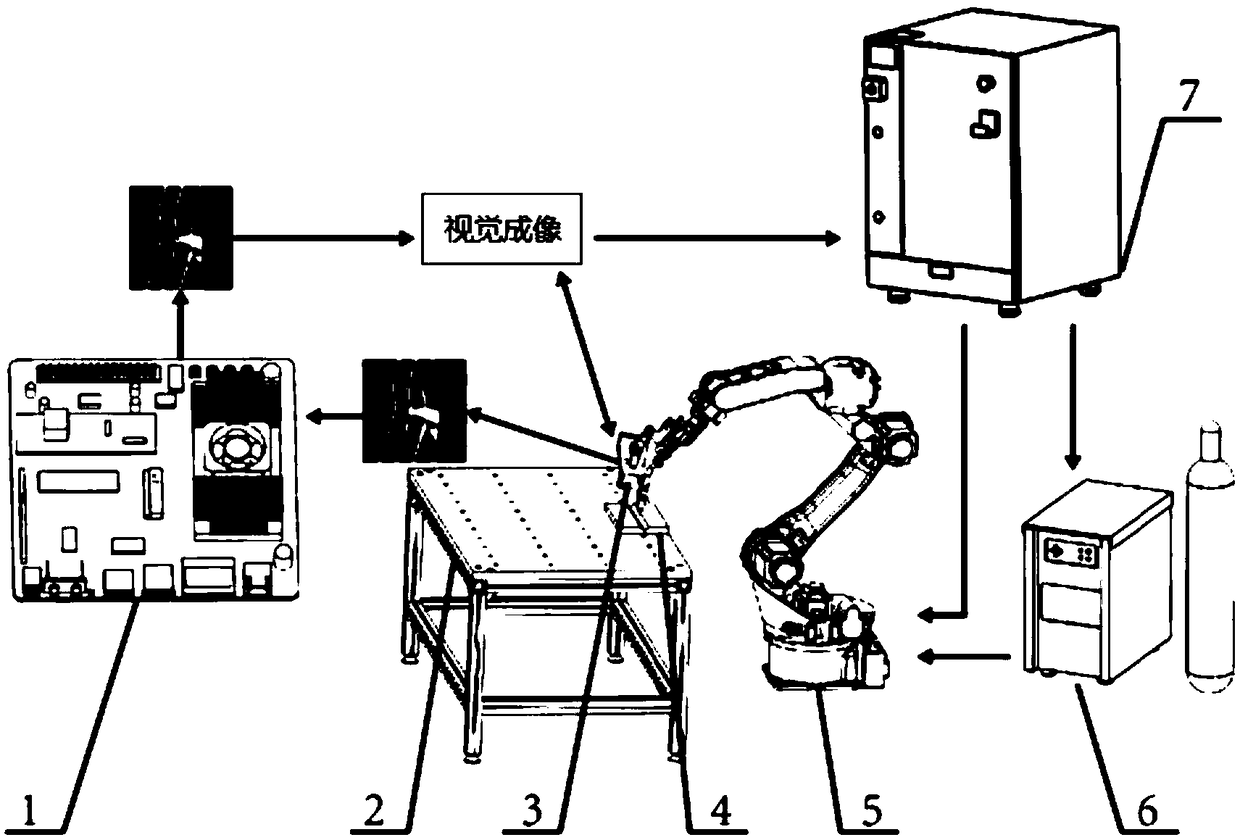

[0068] Such as Figure 1-3 As shown, an automatic measurement system for weld trajectory includes an embedded development board 1 , a laser vision sensor 3 , a welding robot 5 , a robot controller 7 , matching welding equipment 6 , and a workpiece clamping workbench 2 .

[0069] A welding torch is installed on the end flange of the welding robot through a fixing piece. The laser vision sensor is installed parallel to the welding torch in advance of the welding direction to extract the weld seam image information in real time. The robot controller provides control signals. The welding machine and supporting shielding gas are Welding provides energy and materials. The embedded development board is connected with the laser vision sensor via Ethernet. Accurate online automatic welding can be realized.

[0070] The workpiece clamping workbench in this embodiment includes an aluminum profile bracket and a support plate. The cross-sectional size of the aluminum profile bracket is 6...

Embodiment 2

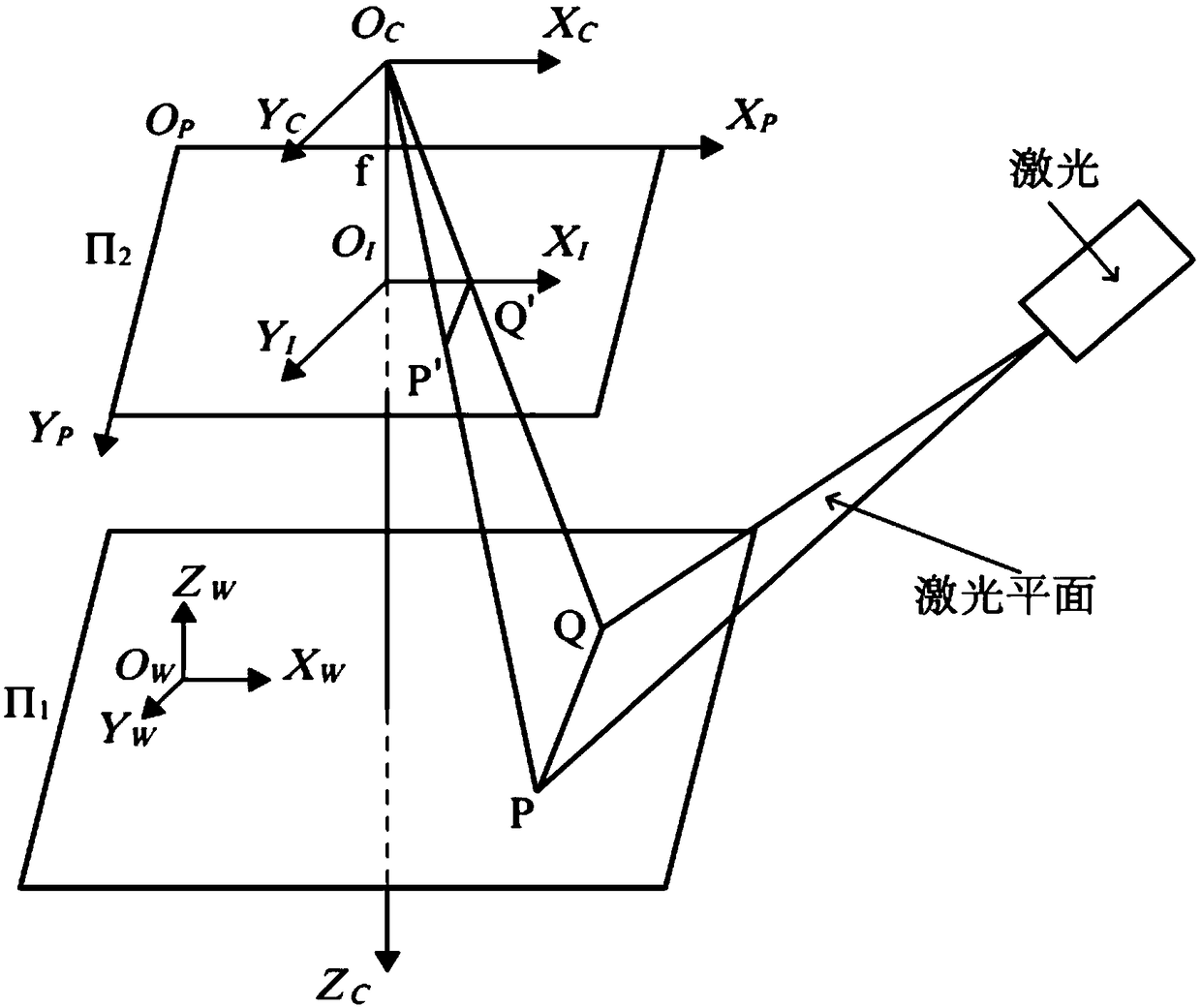

[0075] Such as Figure 4 , 6 As shown, a method for online measurement of weld feature point position. Include steps:

[0076] S1. Adjust the spatial position and posture of the welding robot so that the sharp point of the welding torch moves to the initial welding position, the laser line is irradiated obliquely on the workpiece, and the laser stripes representing the contour information of the weld must be within the field of vision;

[0077]S2. Before welding starts, the camera in the laser vision sensor collects the first frame of weld seam image without arc light, and sends it to the embedded development board TX2 by Ethernet, initializes the image information through the interactive program and manually locates the initial features point to get the starting position of the weld;

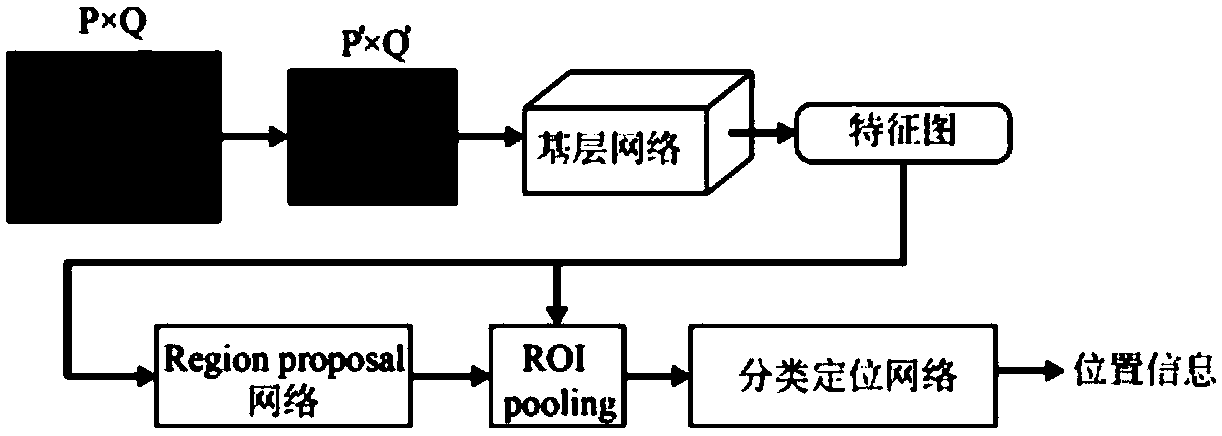

[0078] S3. After the welding starts, the camera of the laser vision sensor continuously collects weld seam images at a sampling frequency of 50 Hz, and sends them to the image processor thro...

Embodiment 3

[0102] Such as Figure 4-5 , 7, an online measurement method for the position of weld feature points. Include steps:

[0103] S1. Adjust the spatial position and posture of the welding robot so that the sharp point of the welding torch moves to the initial welding position, the laser line is obliquely irradiated on the workpiece, and the laser stripes representing the contour information of the weld must be within the field of vision.

[0104] S2. Before welding starts, the camera in the laser vision sensor collects the first frame of weld seam image without arc light, and sends it to the embedded development board TX2 by Ethernet, initializes the image information through the interactive program and manually locates the initial features point to get the starting position of the weld;

[0105] S3. After the welding starts, the camera of the laser vision sensor continuously collects weld seam images at a sampling frequency of 50 Hz, and sends them to the image processor throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com