Fluorinated graphene, and preparation method and application thereof

A technology of fluorinated graphene and graphene, applied in the field of materials, can solve the problems of high process cost and low fluorinated quality, and achieve the effects of improved reaction efficiency, high fluorinated degree, and high fluorinated structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

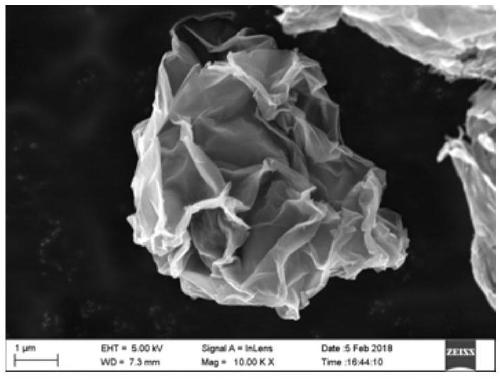

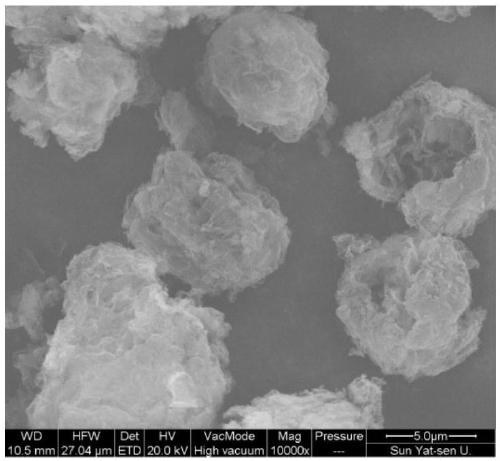

[0048] Preparation of reduced graphene: Weigh 100g of LDGO2211 powder and put it into a quartz tube furnace, seal and evacuate to 0.1Mpa, set the program to raise the temperature to 600°C at 10°C / min, keep it warm for 2 hours, and cool down to room temperature naturally at the end of the program , that is, the wrinkled spherical reduced graphene is obtained.

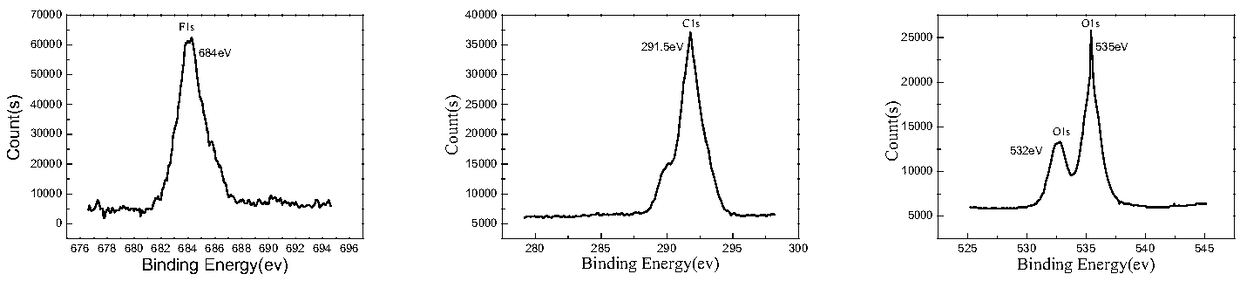

[0049] Preparation of fluorinated graphene: Take 30 g of the above-mentioned reduced graphene with wrinkled spherical structure and import it into a closed fluorinated reaction kettle. Under the vacuum condition of 0.1Mpa, the temperature is raised to 200°C at a rate of 5°C / min, and the temperature is kept for 3 hours. Impurity removal and purification treatment; pass through 3% F 2 / N 2 The mixed gas is heated to 350°C at a rate of 10°C / min, kept for 20 hours, and naturally cooled to room temperature to obtain fluorinated graphene.

Embodiment 2

[0051] Preparation of reduced graphene: Weigh 100g of LDGO2211 powder and put it into a quartz tube furnace, seal it and evacuate it to 0.1Mpa, set the program to raise the temperature to 800°C at 10°C / min, keep it warm for 2 hours, and cool down to room temperature naturally after the end of the program , that is, the wrinkled spherical reduced graphene is obtained.

[0052] Preparation of fluorinated graphene: Take 30 g of the above-mentioned reduced graphene with wrinkled spherical structure and import it into a closed fluorinated reaction kettle. Under the vacuum condition of 0.1Mpa, the temperature is raised to 200°C at a rate of 5°C / min, and the temperature is kept for 3 hours. Impurity removal and purification treatment; pass through 1% F 2 / N 2 The mixed gas is heated up to 300°C at a rate of 10°C / min, kept for 20 hours, and cooled naturally to room temperature to obtain fluorinated graphene.

Embodiment 3

[0054] Preparation of reduced graphene: Weigh 100g of LDGO2211 powder and put it into a quartz tube furnace, seal and evacuate to 0.1Mpa, set the program to raise the temperature to 600°C at 10°C / min, keep it warm for 5 hours, and cool down to room temperature naturally at the end of the program , that is, the wrinkled spherical reduced graphene is obtained.

[0055] Preparation of fluorinated graphene: Take 30 g of the above-mentioned reduced graphene with wrinkled spherical structure and import it into a closed fluorinated reaction kettle. Under the vacuum condition of 0.1Mpa, the temperature is raised to 200°C at a rate of 5°C / min, and the temperature is kept for 3 hours. Impurity removal purification treatment; pass through, 5% F 2 / N 2 The mixed gas is heated up to 450°C at a rate of 10°C / min, kept for 30 hours, and cooled naturally to room temperature to obtain fluorinated graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Ash | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com