Bone china manufacturing method, and bone china products produced using bone china manufacturing method

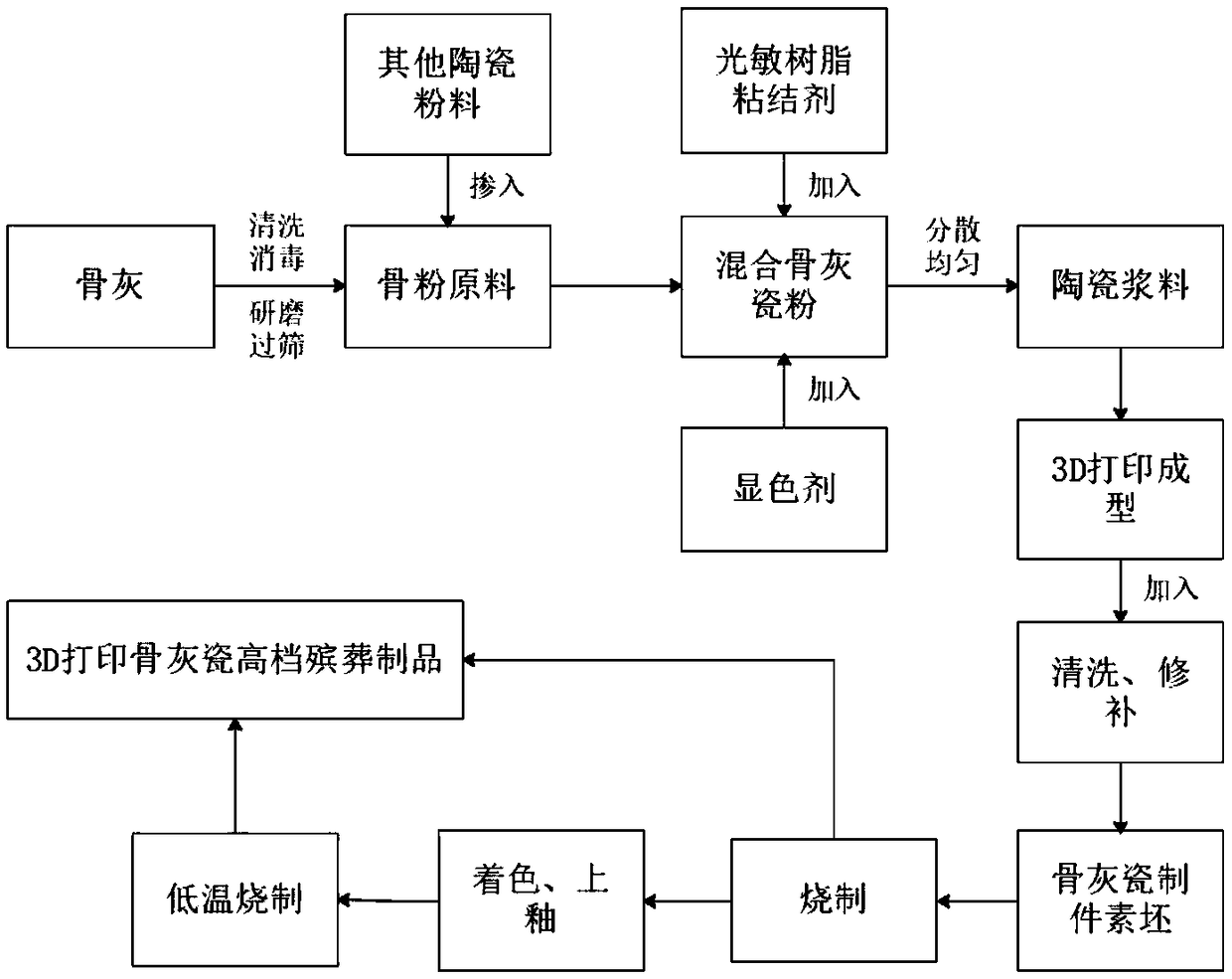

A production method and technology of bone china, which are applied in the production of ceramic materials, clay products, manufacturing tools, etc., can solve problems such as inapplicability, and achieve the effects of low cost, crack prevention, and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The collected human ashes were ground with a ball mill at room temperature for 10 hours, and then passed through a 100-mesh sieve. Measure 100 g of the sieved bone ash powder, and mix it with 100 g of zirconia powder in a mixer to obtain a powder mixture.

[0051] Take 40 g of 1,6-ethylene glycol diacrylate, 8 g of epoxy acrylate, 8 g of water, 4 g of diethyl phthalate, 4 g of sodium polyacrylate, 0.8 g of 1-hydroxycyclohexyl phenyl ketone and 0.4g of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole was uniformly mixed to obtain an adhesive composition, 40g of the above-mentioned adhesive composition was mixed with 200g of the above-mentioned powder mixture, and Ball milled in a ball mill for 12 h to obtain a uniform and stable ceramic slurry.

[0052] The plaster model of the clothing model is used as a substitute for simulating the dead body for 3D scanning, and the 3D data of the model is obtained, which is imported into a light-curing 3D printer for 3D printing using th...

Embodiment 2

[0055] The collected human ashes were ground with a ball mill at 400 r / min for 8 hours, and then passed through a 100-mesh sieve. Measure 100g of sieved bone ash powder, mix with 20g alumina, 10g zirconia and 10g silicon oxide in a mixer, and add 3g Fe 2 O 3 The colorants continue to be mixed to obtain a powder mixture.

[0056] Take 40 g of 1,6-ethylene glycol diacrylate, 6 g of epoxy acrylate, 4 g of water, 6 g of diethyl phthalate, 4 g of sodium polyacrylate, 0.8 g of 1-hydroxycyclohexyl phenyl ketone and 0.6g of 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole was uniformly mixed to obtain an adhesive composition, and 50 g of the adhesive composition was obtained The mixture was mixed with 143 g of the above powder mixture, and after ball milling in a ball mill for 8 hours, vacuum defoamed for 5 minutes to obtain a uniform and stable ceramic slurry.

[0057] Based on the portrait photo, use the photo reconstruction technology of VisualSFM or Agisoft Ph...

Embodiment 3-4

[0060] Prepared in the same manner as in Examples 1-2, except that known models of rings, pendants, earrings and bracelets were used in 3D printing molding, and blanks were obtained as gem-shaped inlay models to obtain Example 3 - Various decorative products as described in 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com