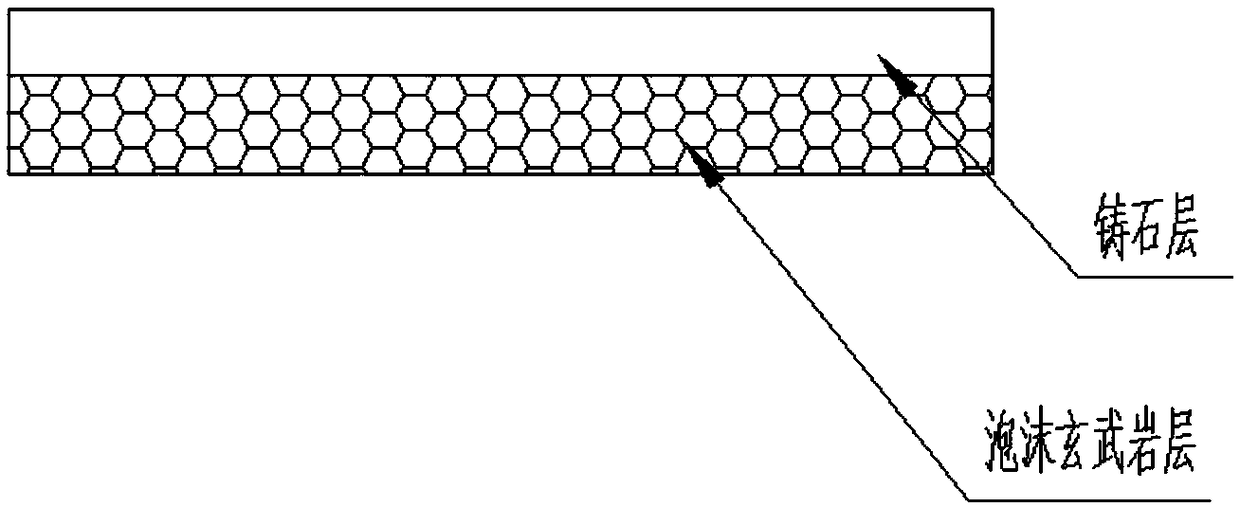

Composite foam basalt cast stone board and preparation process thereof

A composite foam and preparation technology, which is applied in the direction of lamination, layered products, lamination devices, etc., can solve the problems of cement mortar not sticking firmly, not guaranteeing the bonding strength, and affecting the use effect, so as to reduce the burden of equipment support , stick firmly, low moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation process for composite foam basalt cast stone slabs, comprising the following steps:

[0028] (1) The base material will be prepared with auxiliary materials as raw materials for producing cast stone plates, wherein the raw materials of cast stone plates include the following raw materials in parts by weight: SiO 2 : 43~48%, Al 2 o 3 : 12~16%, Fe 2 o 3 +FeO: 12-15%, CaO: 8-13%, MgO: 4-8%;

[0029] (2) Cut the foam basalt into the required size, put it into the mold and heat it to 500-600°C;

[0030] (3) Melt the raw materials for the production of cast stone plates at 1300°C and pour the melted cast stone magma onto the foam basalt surface in the mold, pouring 5mm, using a multi-point pouring method, pouring from one end to the other according to the size of the plate A certain thickness, then push the mold and move gradually until the board surface is as flat as the mold, and the pouring temperature is controlled at 1250°C;

[0031] (4) After the sur...

Embodiment 2

[0034] A preparation process for composite foam basalt cast stone slabs, comprising the following steps:

[0035] (1) The base material will be prepared with auxiliary materials as raw materials for producing cast stone plates, wherein the raw materials of cast stone plates include the following raw materials in parts by weight: SiO 2 : 43~48%, Al 2 o 3 : 12~16%, Fe 2 o 3 +FeO: 12-15%, CaO: 8-13%, MgO: 4-8%;

[0036] (2) Cut the foam basalt into the required size, put it into the mold and heat it to 500-600°C;

[0037](3) Melt the raw materials for the production of cast stone plates at a temperature of 1350°C and pour the melted cast stone magma onto the surface of the foam basalt in the mold, pouring 10mm, using a multi-point pouring method, and pouring from one end to the other according to the size of the plate. After a certain thickness, push the mold and move it step by step until the surface of the plate is as flat as the mold, and the pouring temperature is contro...

Embodiment 3

[0041] A preparation process for composite foam basalt cast stone slabs, comprising the following steps:

[0042] (1) The base material is prepared with auxiliary materials to be used to produce raw materials for cast stone plates, wherein the raw materials for cast stone plates include the following raw materials in parts by weight: SiO 2 : 43~48%, Al 2 o 3 : 12~16%, Fe 2 o 3 +FeO: 12-15%, CaO: 8-13%, MgO: 4-8%;

[0043] (2) Cut the foam basalt into the required size, put it into the mold and heat it to 500-600°C;

[0044] (3) Melt the raw materials for the production of cast stone plates at a temperature of 1400°C and pour the melted cast stone magma onto the surface of the foam basalt in the mold, pouring 15mm, using a multi-point pouring method, according to the size of the plate from one end to the other. After a certain thickness, push the mold and move it step by step until the plate surface is as flat as the mold, and the pouring temperature is controlled at 1200°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com