Method for preparing 3,5-dichlorophenyl isocyanate by microchannel reactor

A technology of dichlorophenyl isocyanate and microchannel reactor, which is applied in chemical instruments and methods, preparation of isocyanate derivatives, preparation of organic compounds, etc., can solve the problems of long reaction time, high environmental protection pressure and high production cost , to achieve the effect of improved reaction yield, less equipment corrosion and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

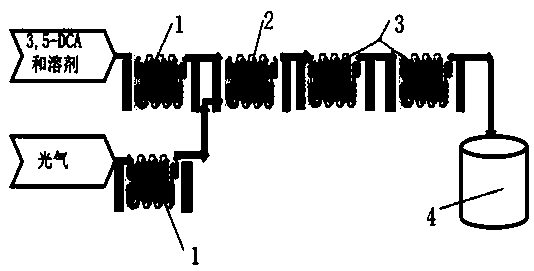

[0053] (1) Preparation link: Press figure 1 Assemble the Corning microchannel continuous flow reactor, and mix 3,5-dichloroaniline and toluene uniformly in a mass ratio of 1:1 to obtain a 3,5-dichloroaniline solution.

[0054] (2) Complete in sequence in Corning microchannel continuous flow reactor: set the flow control of each raw material metering pump so that the molar ratio of 3,5-dichloroaniline and phosgene is 1:1.1, and control the 3,5-dichloroaniline solution The mass flow rate of phosgene is 27g / min, the mass flow rate of phosgene is controlled to be 10g / min, the 3,5-dichloroaniline solution and phosgene are respectively injected into the preheating module 1 of Corning microchannel reactor, and the temperature is controlled to 80℃ and the pressure is 0.5MPa, then enter the first microchannel reactor 2 for mixed reaction, the reaction residence time is 15s, and then pass into the subsequent two serial microchannel reactors 3, the reaction residence time in each microchann...

Embodiment 2

[0057] (1) Preparation link: Press figure 1 Assemble the Corning microchannel continuous flow reactor, mix 3,5-dichloroaniline and toluene uniformly at a mass ratio of 1:1 to obtain a 3,5-dichloroaniline solution.

[0058] (2) Complete in sequence in Corning microchannel continuous flow reactor: set the flow control of each raw material metering pump so that the molar ratio of 3,5-dichloroaniline and phosgene is 1:1.1, and control the 3,5-dichloroaniline solution The mass flow rate of phosgene is 20g / min, the mass flow rate of phosgene is controlled to be 7.4g / min, and the 3,5-dichloroaniline solution and phosgene are respectively injected into the preheating module 1 of Corning microchannel reactor, and the temperature is controlled at 80℃, and the pressure It enters the first microchannel reactor 2 for mixed reaction, and the reaction residence time is 15s, and then passes into the subsequent two series-connected microchannel reactors 3, and the reaction in each microchannel re...

Embodiment 3

[0061] (1) Preparation link: Press figure 1 Assemble the Corning microchannel continuous flow reactor, mix 3,5-dichloroaniline and toluene uniformly at a mass ratio of 1:1 to obtain a 3,5-dichloroaniline solution.

[0062] (2) Complete in sequence in Corning microchannel continuous flow reactor: set the flow control of each raw material metering pump so that the molar ratio of 3,5-dichloroaniline and phosgene is 1:1.1, and control the 3,5-dichloroaniline solution The mass flow rate of phosgene is 15g / min, and the mass flow rate of phosgene is controlled at 5.6g / min. The 3,5-dichloroaniline solution and phosgene are respectively injected into the preheating module 1 of the Corning microchannel reactor, and the temperature is controlled at 80℃ and the pressure It enters the first microchannel reactor 2 for mixed reaction, and the reaction residence time is 15s, and then enters the subsequent two series-connected microchannel reactors 3, and the reaction in each microchannel reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com