PPA type pectin self-healing hydrogel and preparation method of capacitance-type sensor thereof

A capacitive sensor, self-healing technology, applied in the direction of fluid pressure measurement, instrument, electromagnetic measurement device using capacitance change, to achieve stable performance, high resolution, and increase the effect of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

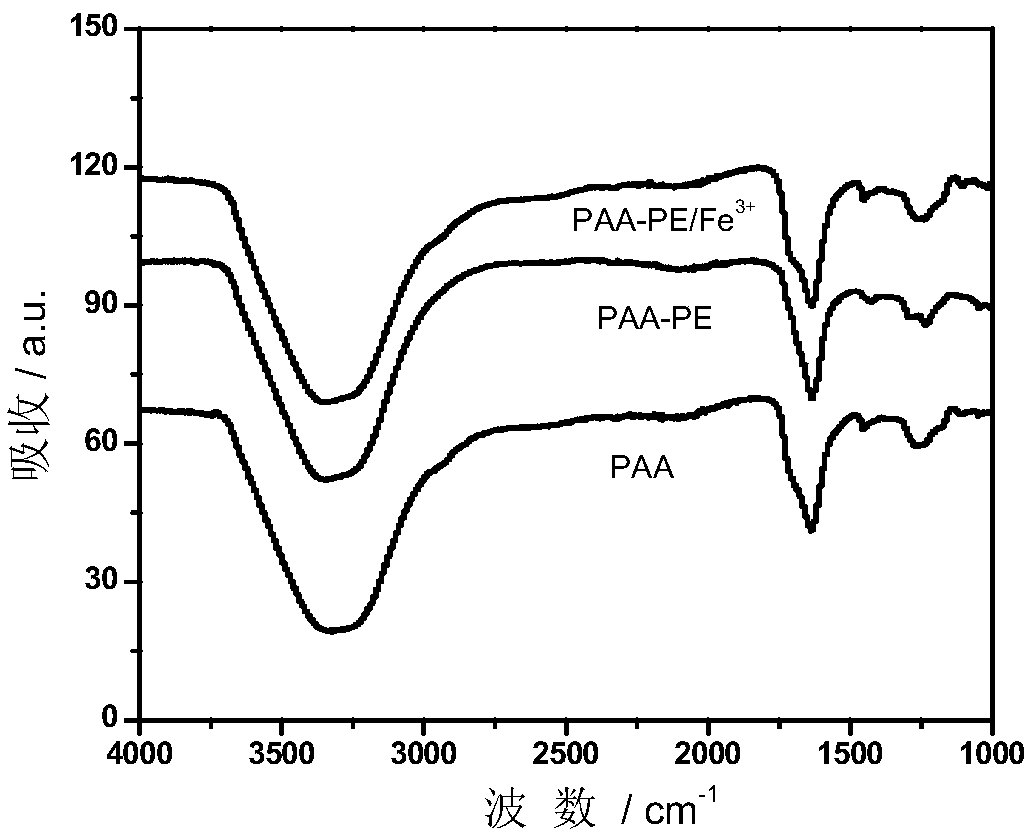

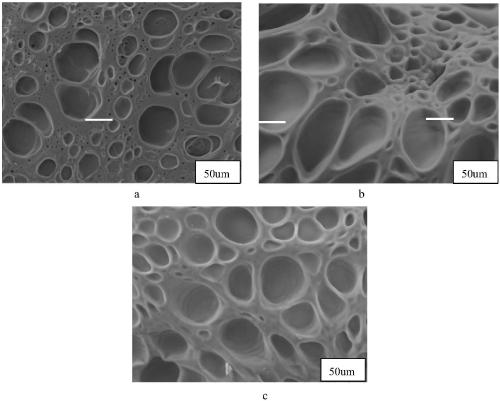

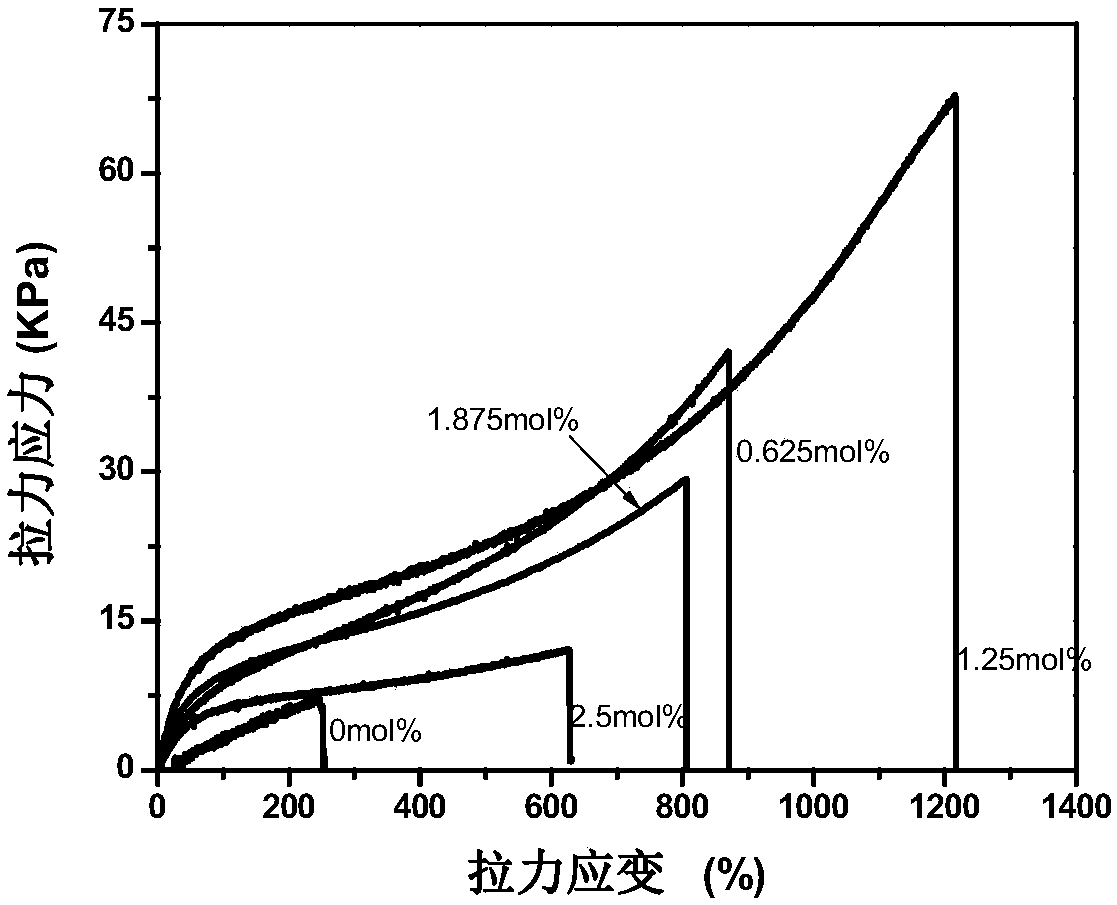

[0033] Take 2g of acrylic acid, 0.031g of pectin, 4mg of MBAA, 40mg of APS, and add FeCl with a concentration of 0-2.5mol% relative to the amount of acrylic acid 3 .6H 2O, stir in 10mL of aqueous solution for 30 minutes and mix evenly, pass nitrogen gas for 30 minutes to remove the gas in the solution, pour the solution into a polytetrafluoroethylene mold, polymerize at 60 degrees Celsius for 60 minutes, and obtain different Fe 3+ concentrated hydrogel. When the pectin content in the hydrogel is 6.2wt%, FeCl 3 .6H 2 When the O content is 0 mol%, it is labeled as PAA-PE hydrogel.

Embodiment 2

[0035] Change Example 1 to get 2g acrylic acid, 4mg MBAA, 40mg APS, 1.25mol% FeCl 3 .6H 2 O, add pectin that is 1.55-15.5wt% relative to the mass concentration of acrylic acid, stir in 10mL of aqueous solution for 30 minutes and mix evenly, pass nitrogen gas for 30 minutes to remove the gas in the solution, and polymerize at 60 degrees Celsius for 60 minutes to obtain Hydrogels with different pectin concentrations. When the pectin content is 0wt%, FeCl 3 .6H 2 When the O content is 0 mol%, it is labeled as PAA hydrogel. When the pectin content is 1.55wt%, FeCl 3 .6H 2 When the O content is 1.25mol%, it is labeled as PAA-PE / Fe 3+ Hydrogels.

Embodiment 3

[0037] First of all, the specific method of making the PDMS layer is as follows: mix the PDMS uniformly according to the mass ratio: 10:1 (the American Dow Corning Sylgard184 silicone rubber is a two-component kit composed of liquid components, and the density is 1.04g / ml) to mix the mixture evenly, and then Degas to remove air bubbles, pour the uncured mixture into a polytetrafluoroethylene mold, and after heating at 80 °C for 1 hour, a PDMS film with a thickness of 10 mm × 20 mm and a thickness of 0.352 mm can be formed. Take the above PDMS as the middle layer, with PAA-PE / Fe of the same size on both sides 3+ Hydrogel, the three are closely attached, and a copper wire is sandwiched between the hydrogel and PDMS interlayers, so that the two copper wires are at the opposite positions. A capacitive pressure sensor with a "sandwich" structure of self-healing hydrogel at both ends and polydimethylsiloxane (PDMS) as the middle dielectric layer was obtained. Finally, the manufactu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com