Polydimethylsiloxane-double-scale silica composite superhydrophobic coating and its forming method

A polydimethylsiloxane, superhydrophobic coating technology, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

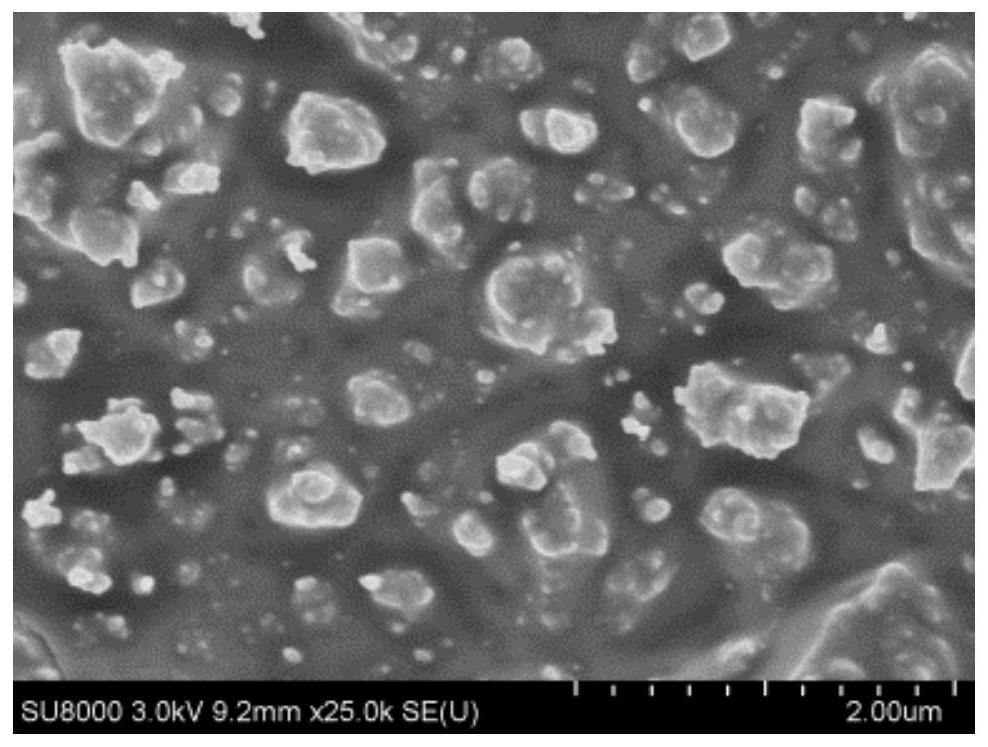

Image

Examples

Embodiment 1

[0038] (1) Preparation of silica nanoparticles

[0039] First, 90ml of absolute ethanol, 3.9ml of ammonia water (mass fraction 25%), and 3.9ml of pure water were blended in a round bottom flask, magnetically stirred at 500r / min, and after stirring for 5min, 2.1ml of orthosilicic acid was added to the above mixed solution. Ethyl ester (analytically pure, the same below), the reaction was carried out for 4h. After the reaction was completed, the mixed solution was placed in a sample tube for centrifugation. The centrifuge speed is 6000r / min, and the centrifugation time is 3min. After the centrifugation is completed, a solid-liquid separation system with a white precipitate at the bottom and a clear upper layer is obtained. The white precipitate at the bottom was repeatedly washed with absolute ethanol several times, and then dried in a 60°C drying oven for 5 hours to obtain silica nanoparticles. The average particle diameter was determined to be 200nm.

[0040] (2) Take 0.05 g...

Embodiment 2

[0047] (1) Preparation of silica nanoparticles

[0048] First, 60ml of absolute ethanol, 8ml of ammonia water (mass fraction 25%), and 3.9ml of pure water were blended in a round-bottomed flask, the reaction temperature was 40°C, and magnetic stirring was performed at 500r / min. After stirring for 5min, add 5ml of ethyl orthosilicate, the reaction was carried out for 6h. After the reaction is completed, the mixture is placed in a sample tube for separation. The centrifuge speed is 6000r / min, and the centrifugation time is 3min. After the centrifugation is completed, a solid-liquid separation system with a white precipitate at the bottom and a clear upper layer is obtained. The white precipitate at the bottom was repeatedly washed with absolute ethanol several times, and then dried in a 60°C drying oven for 5 hours to obtain silica nanoparticles. The average particle diameter was measured to be 500nm.

[0049] (2) Take 0.05 g of the above-mentioned silica nanoparticles in a s...

Embodiment 3

[0054] (1) Preparation of silica nanoparticles

[0055] First, blend 90ml of absolute ethanol, 3.9ml of ammonia water, and 3.9ml of pure water into a round-bottomed flask, stir magnetically at 500r / min, and after stirring for 5min, add 2.1ml of ethyl orthosilicate to the above mixture, and react for 4h .Place the mixed solution after the reaction in the sample tube for separation. The centrifuge speed is 6000r / min, and the centrifugation time is 3min. After the centrifugation is completed, a solid-liquid separation system with a white precipitate at the bottom and a clear upper layer is obtained. The white precipitate at the bottom was repeatedly washed with absolute ethanol several times, and then dried in a 60°C drying oven for 5 hours to obtain silica nanoparticles. The average particle diameter was determined to be 200nm

[0056] (2) Take 0.2 g of the above silica nanoparticles in a sample tube, add 2 ml of ethyl acetate, vibrate with an oscillator for 5 min, and then ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com