External fire down-flow fixed bed type front-furnace carbonization-coupling fire coal power generating device for straws

A power generation device and bed furnace technology, applied in coking ovens, biofuels, indirect heating and dry distillation, etc., can solve problems such as corrosion and slagging, and achieve precise temperature reduction, low tar content, and precise control of calorific value and temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

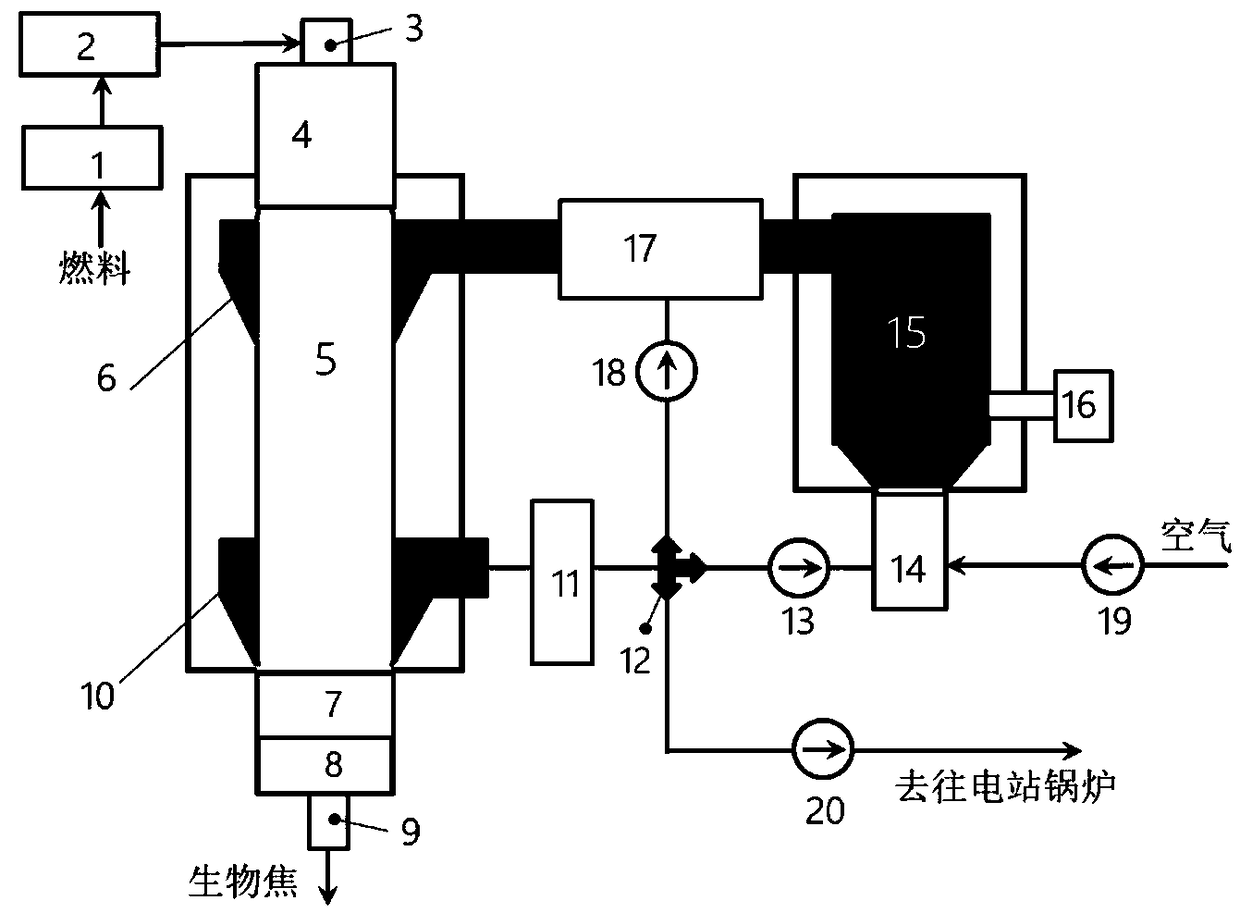

[0016] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0017] combine figure 1 , a carbonization coupled coal-fired power generation device in front of a straw external combustion downstream fixed bed furnace of the present invention, including a conveyor 1, a feeder 2, an air lock 3, a main silo 4, a carbonization chamber 5, and an air distribution chamber 6 , slagging chamber 7, gas collector 10, heat exchanger 11, four-way valve 12, first circulating fan 13, burner 14, combustion chamber 15, ignition burner 16, regulating chamber 17, second circulating fan 18, Fan 19, fourth circulation fan 20, monitoring unit;

[0018] The conveyor 1 is connected to the inlet of the feeder 2 to transport straw; the outlet of the feeder 2 is connected to the inlet of the air locker 3, and the function of the air locker ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com