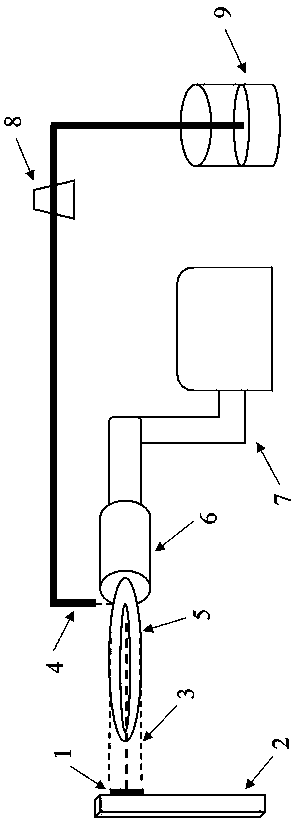

Composite soft form board liquid material plasma spray method for preparing gas-sensitive coating of hollow micro-nano structure

A micro-nano structure, plasma technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problems of single coating structure and morphology, poor gas sensing performance, uncontrollable and other problems, and achieve uniform particle distribution. , Improve work efficiency, the effect of fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

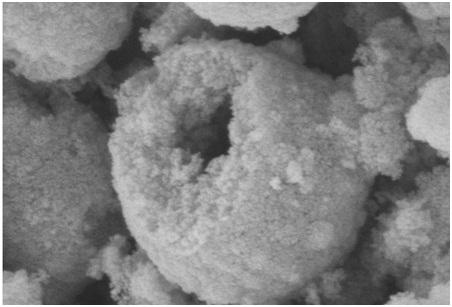

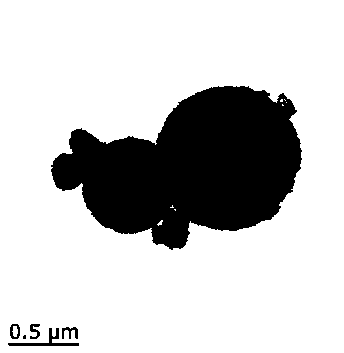

Examples

Embodiment 1

[0026] 1. Alumina was used as the insulating matrix, and a 30×10×1 mm alumina sheet was placed in deionized water and ethanol in sequence, and assisted by ultrasound, cleaned for 10 minutes, and dried at 80°C for later use. A layer of chromium with a thickness of 0.3 µm was first prepared using a metal mask pattern by vacuum coating to improve the bonding strength, and then a layer of 0.5 µm gold was vapor-deposited on the front of the alumina sheet to obtain an interdigitated electrode. On the opposite side of the alumina sheet, a layer of chromium with a thickness of 0.3 µm was first prepared by vacuum coating to improve the bonding strength, and then a layer of 0.5 µm platinum was evaporated on the front of the alumina sheet to obtain an interdigital heating electrode. That is, the sensor substrate 2 .

[0027] 2. Under magnetic stirring at 80°C, weigh 3.2 g of DL-aspartic acid and dissolve it in 360 mL of deionized water and stir for 10 min, then add 400 mL of 0.1 mol / L ...

Embodiment 2

[0031] The difference between this embodiment and Example 1 is that: 50 mL 0.3 mol / L Zn(NO 3 ) 3 solution. The spray current selected in step 4 is 412 A, H 2 With a flow rate of 4 L / min and a spraying distance of 60 mm, a hollow micro-nano-structured ZnO coating with a thickness of 20 µm was prepared, and then heat-preserved at 200 °C for 48 hours. When the test condition is 50°C, the coating is resistant to 10 ppm NO 2 The sensitivity is 32.5.

Embodiment 3

[0033] The difference between this embodiment and Example 1 is: what is added is 40 mL 0.2 mol / L Na 2 WO 4 solution. The spray current selected in step 4 is 512 A, H 2 When the flow rate is 5 L / min and the spraying distance is 75 mm, the hollow micro-nano structure WO 3 Coating, heat preservation treatment at 200°C for 48 hours. When the test conditions are room temperature, the coating is 10 ppm NO 2 The sensitivity is 16.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com