Enameled wire with high electrical conductivity and preparation method thereof

An enameled wire, highly conductive technology, applied in the parts of the conductive core, conductive materials, conductive materials and other directions, can solve the problems of high cost and complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

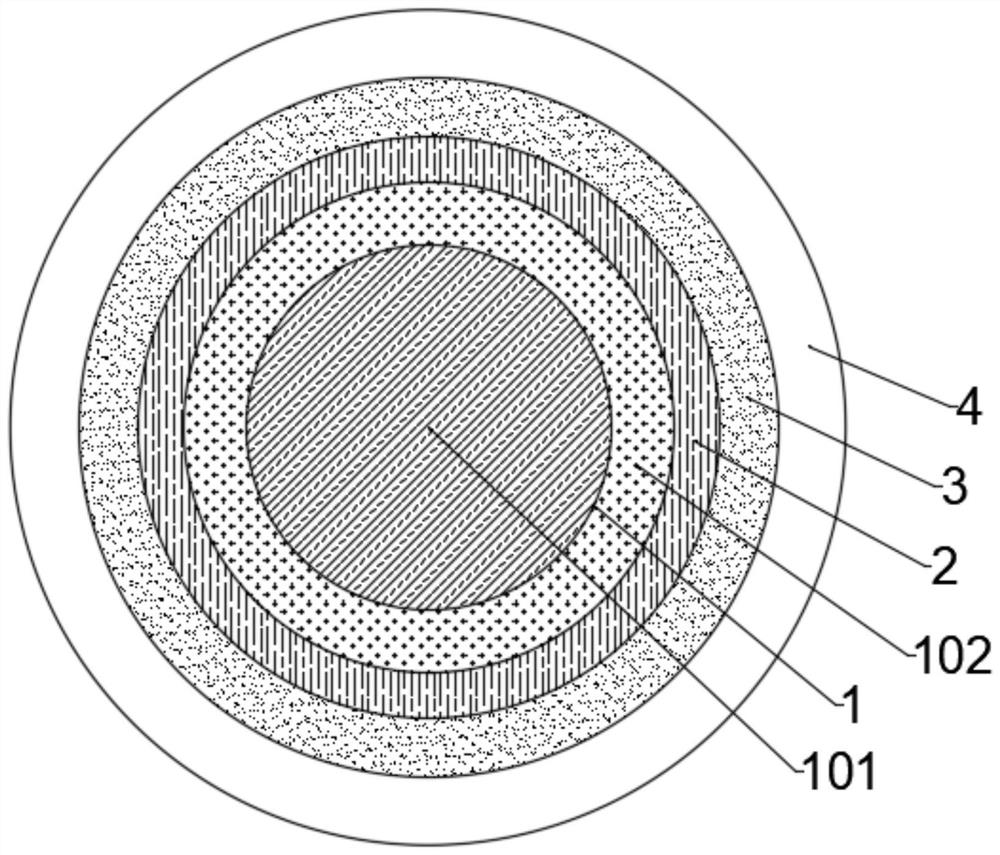

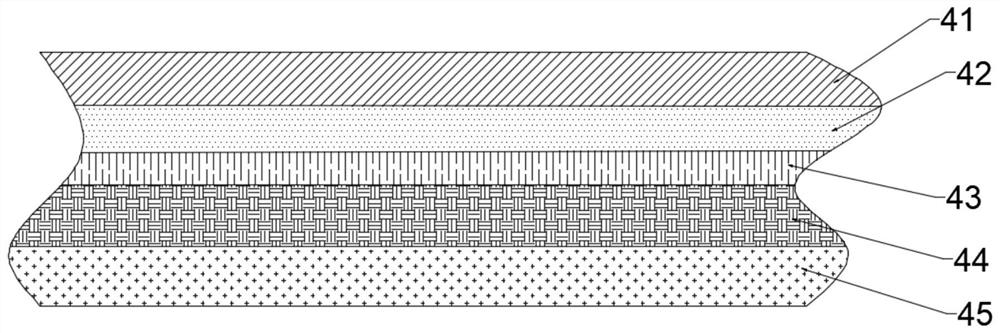

[0032] Such as figure 1 As shown, the present invention provides a high-conductivity enameled wire, including a conductive core layer 1, a tensile fiber layer 2 is provided on the surface of the conductive core layer 1, and a plating layer is provided on the surface of the tensile fiber layer 2. Tin layer 3, an insulating varnish layer 4 is provided on the surface of the tin-plated layer 3, the conductive core layer 1 includes a nano-silver-copper alloy core 101, and inorganic insulating microparticles are provided on the surface of the nano-silver-copper alloy core 101 layer 102, the tensile fiber layer 2 is wound on the surface of the inorganic insulating microparticle layer 102 by a number of carbon fiber filaments interlaced and spirally wound in forward and reverse directions.

[0033] In this embodiment, the main purpose is to improve the conductivity. For precision equipment that requires extremely high conductivity, in the prior art, there is an alloy silver wire to in...

Embodiment 2

[0059] The invention provides a method for preparing an enameled wire with high electrical conductivity, comprising the following steps:

[0060] Step 100, obtaining nano-silver-copper alloy by electrolysis, and smelting, and obtaining a nano-silver-copper alloy core of required specifications by rolling and stretching processes;

[0061] Step 200, quenching the nano-silver-copper alloy core, and passing it into deionized water for rapid cooling after reaching the quenching temperature;

[0062] Step 300, after the nano-silver-copper alloy core is cooled, put it into the tempering equipment to heat and keep it warm, and then naturally cool to normal temperature;

[0063] Step 400, coating the tensile fiber layer and the tin-plated layer in turn, and then sending it into a paint coater to coat the insulating paint layer;

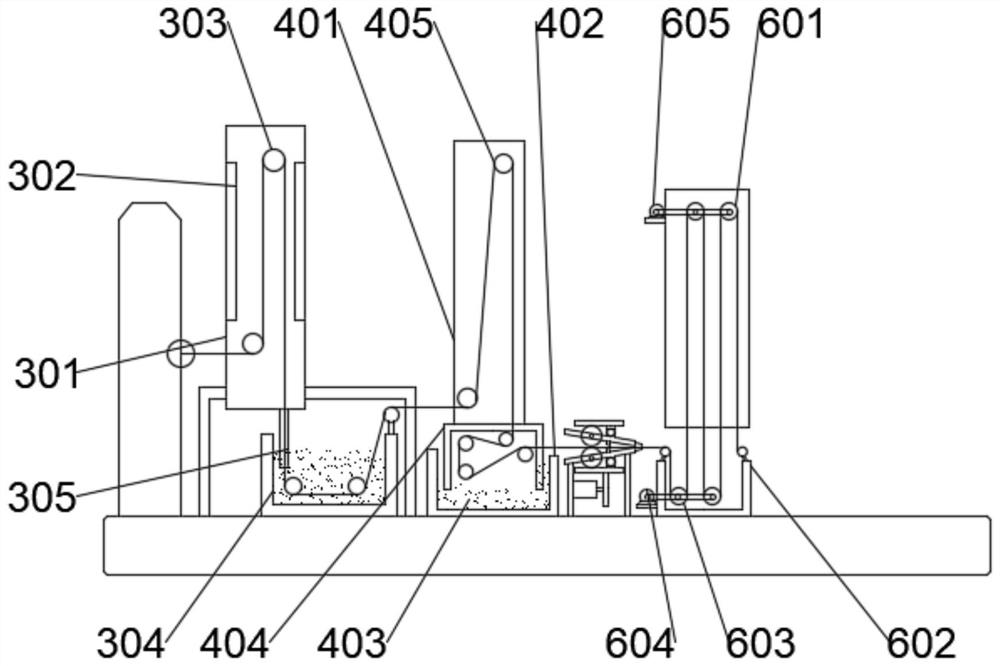

[0064] Such as image 3 As shown, the quenching process in step 200 is carried out by a dedicated quenching device, which includes a constant temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com