A method for sorting and recycling valuable components of waste power lithium batteries

A lithium battery and power technology, which is applied in the field of secondary resource recovery and utilization, can solve problems such as unfavorable industrial production, waste of resources, and poor electrochemical performance, and achieve the effects of simplifying the steps of discharge treatment, improving production efficiency, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

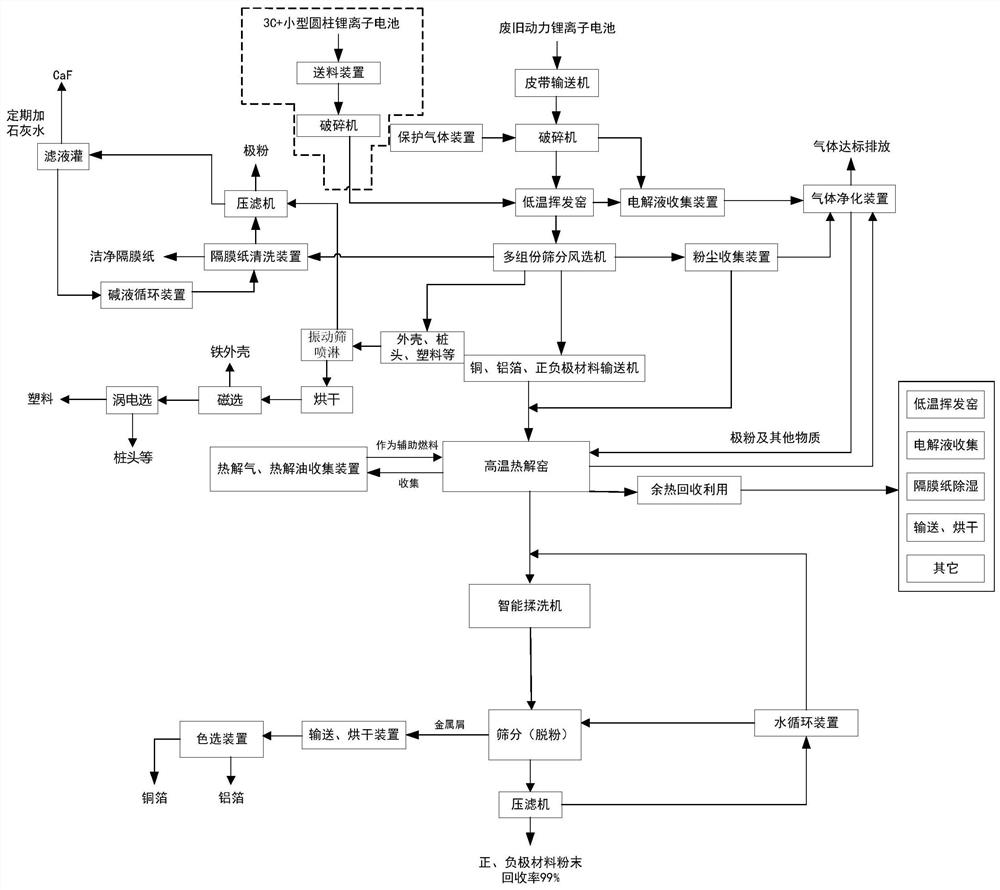

[0056] 1) The charged scrap lithium iron phosphate battery is crushed in a shear crusher with a sealed cavity and nitrogen protection; during the crushing process, an organic solvent is used to absorb the electrolyte evaporated from the crusher;

[0057] 2) Use a multi-component screening winnowing machine to screen out fine-grained materials from the crushed products, and then use a vertical winnowing machine to sort out light product diaphragms, heavy product shells, pile heads, plastics, and copper foil, Aluminum foil, positive and negative materials;

[0058] 3) The sieve used in step 2 is a sieve hole of 2cm, and the broken product is sieved into two particle sizes of coarse and fine, and the diaphragm in the material is sorted out using a horizontal winnowing machine. It is 13m / s. After secondary separation, the recovery rate of metal is 98.66%, and the recovery rate of diaphragm is 86.18%;

[0059] 4) Immerse the diaphragm collected by winnowing into a clarified lime a...

Embodiment 2

[0068] Use the crushing equipment in Example 1 to crush the waste lithium manganate power lithium-ion battery and evaporate and absorb the electrolyte at low temperature, use a vertical negative pressure winnowing machine to separate the diaphragm and metal, and separate the lithium-ion battery containing The high-temperature pyrolysis of the positive and negative electrode materials, the carbonization of the binder, and the subsequent treatment process are the same as in Example 1. The recovery rate of the final positive and negative electrode active materials was 97.3%, the impurity content was 0.187% Al, Cu 0.087%, the recovery rate of copper was 99.1%, the recovery rate of aluminum was 97.8%, and the recovery rate of separator was 90.3%.

Embodiment 3

[0070] Use the crushing equipment in Example 1 to crush the waste power lithium-ion battery and evaporate and absorb the electrolyte at low temperature, and then use a low-temperature decomposition furnace to decompose lithium hexafluorophosphate. The decomposed HF is absorbed by lye, and the lye after absorption is used regularly. Lime water precipitates the F element in it. A vertical negative pressure air separator was used to separate the separator from the metal, and the metal containing the positive and negative materials was pyrolyzed at 600°C under a nitrogen atmosphere to carbonize the binder, and the subsequent treatment process was the same as in Example 1.

[0071] The recovery rate of the final positive and negative electrode active materials is 99%, the impurity content is Al 0.10%, Cu1.8%, other 0.1%, the recovery rate of copper is 99.1%, the recovery rate of aluminum is 97.75%, and the recovery rate of separator is 98% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com