A kind of preparation method of perovskite micro-laser

A micro-laser, perovskite technology, applied in the field of lasers, can solve the problems of low conversion efficiency of solid-state lasers, difficult laser devices, serious temperature gain ratio, etc., to solve the problems of low conversion efficiency, high carrier mobility, and low threshold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below in conjunction with examples, so as to better understand the present invention.

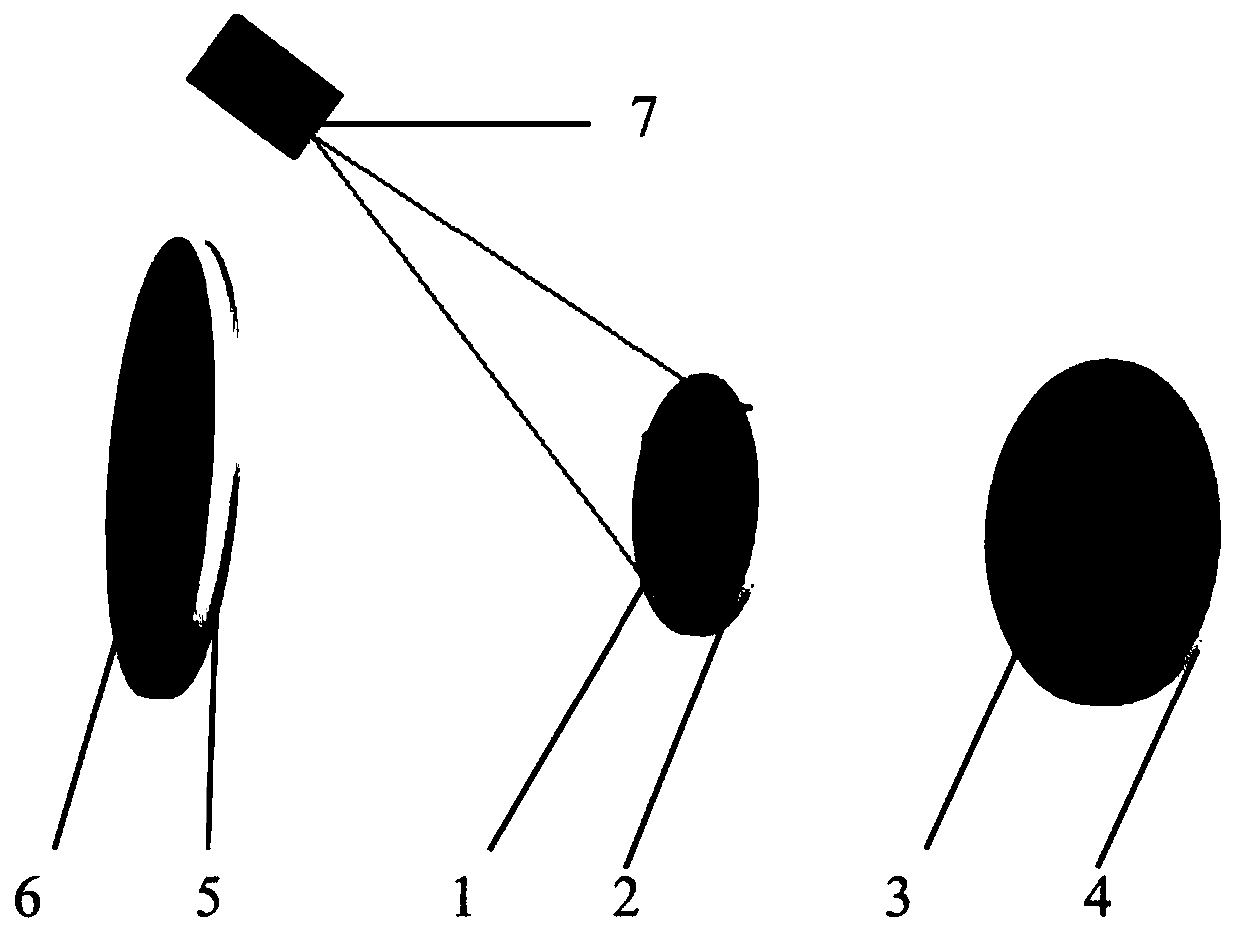

[0017] The present invention proposes a method for preparing a perovskite micro-laser, which uses a perovskite material with high carrier mobility, long diffusion length, large absorption coefficient, and high quantum yield as the gain medium in the laser, The perovskite material is preferably rod-shaped or flake-shaped, and a semiconductor laser array is used as an excitation light source to pump the gain medium of this laser to realize a low-threshold, high-conversion efficiency, and easy-to-implement laser device in different wavelength bands, effectively solving the problem of In the prior art, the conversion efficiency of solid-state lasers is low, the temperature gain ratio is serious, and it is difficult to realize laser devices in different bands.

[0018] The preparation method of a perovskite micro-laser propos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com