A method for realizing exciton laser emission of gallium telluride (gate) two-dimensional material

A two-dimensional material, laser emission technology, applied in phonon exciters, chemical instruments and methods, lasers, etc., can solve the problems of weakened spontaneous emission capability, unsuitable technology for industrialization, and reduced spontaneous emission capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

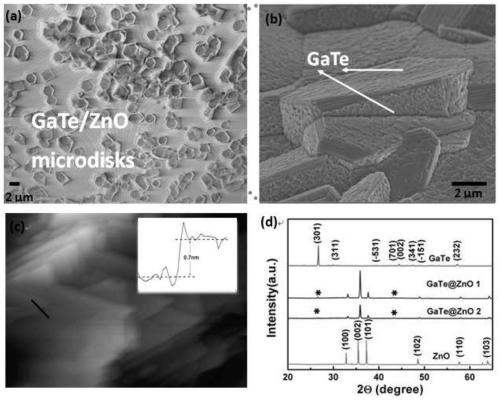

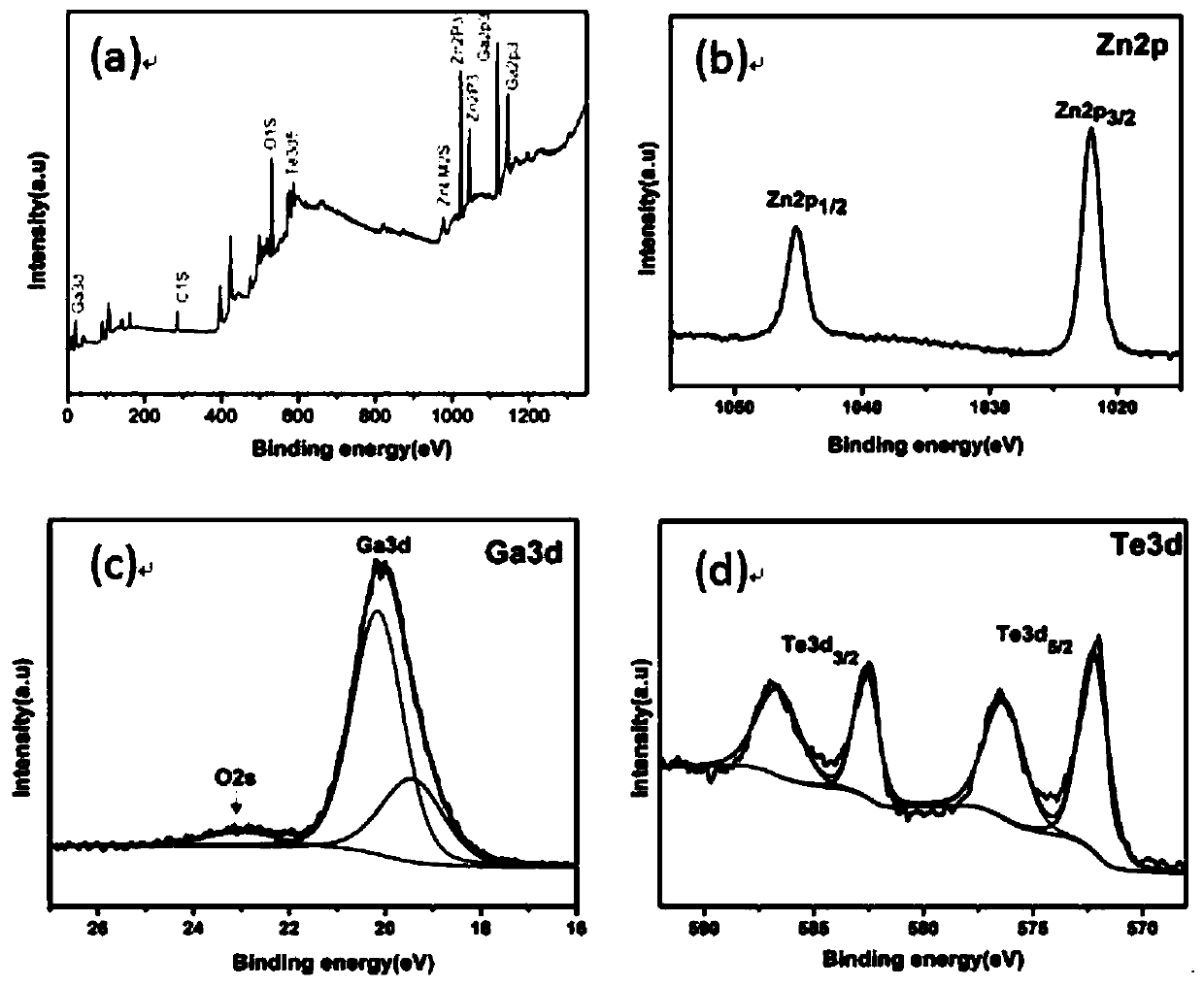

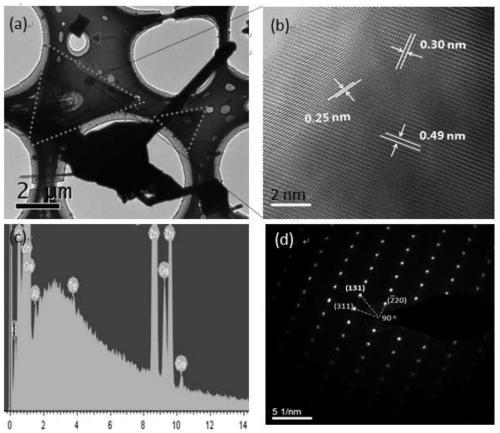

Embodiment 1

[0035] A method for realizing GaTe two-dimensional material exciton laser emission, comprising steps:

[0036] The first step is to clean the sapphire wafer and quartz boat. First, put a sapphire substrate with a size of 1×1cm, a thickness of 0.5mm, and a surface roughness of 0.2nm into a beaker filled with 50ml of ethanol, perform ultrasonic cleaning for 15 minutes, and take it out and blow it dry with a nitrogen gun; Next, put the dried sapphire substrate into another beaker containing 50 ml of acetone, perform ultrasonic cleaning for 15 minutes, take it out and dry it with a nitrogen gun; finally put the dried sapphire substrate into 100 ml of deionized In water, perform ultrasonic cleaning for 10 minutes, take it out and dry it with a nitrogen gun.

[0037]In the second step, the sapphire substrate is annealed. The sapphire substrate cleaned up in the first step is directly put into the double-temperature zone CVD furnace tube produced by Tianjin Zhonghuan Company used ...

Embodiment 2

[0048] A method for realizing GaTe two-dimensional material exciton laser emission, comprising steps:

[0049] The first step is to clean the sapphire wafer and quartz boat. First, put a sapphire substrate with a size of 1×1cm, a thickness of 0.5mm, and a surface roughness of 0.2nm into a beaker filled with 50ml of ethanol, perform ultrasonic cleaning for 15 minutes, and take it out and blow it dry with a nitrogen gun; Next, put the dried sapphire substrate into another beaker containing 50 ml of acetone, perform ultrasonic cleaning for 15 minutes, take it out and dry it with a nitrogen gun; finally put the dried sapphire substrate into 100 ml of deionized In water, perform ultrasonic cleaning for 10 minutes, take it out and dry it with a nitrogen gun.

[0050] In the second step, the sapphire substrate is annealed. The sapphire substrate cleaned up in the first step is directly put into the double-temperature zone CVD furnace tube produced by Tianjin Zhonghuan Company used...

Embodiment 3

[0057] A method for realizing GaTe two-dimensional material exciton laser emission, comprising steps:

[0058] The first step is to clean the sapphire wafer and quartz boat. First, put a sapphire substrate with a size of 1×1cm, a thickness of 0.5mm, and a surface roughness of 0.2nm into a beaker filled with 50ml of ethanol, perform ultrasonic cleaning for 15 minutes, and take it out and blow it dry with a nitrogen gun; Next, put the dried sapphire substrate into another beaker containing 50 ml of acetone, perform ultrasonic cleaning for 15 minutes, take it out and dry it with a nitrogen gun; finally put the dried sapphire substrate into 100 ml of deionized In water, perform ultrasonic cleaning for 10 minutes, take it out and dry it with a nitrogen gun.

[0059] In the second step, the sapphire substrate is annealed. The sapphire substrate cleaned up in the first step is directly put into the double-temperature zone CVD furnace tube produced by Tianjin Zhonghuan Company used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com