Tea aroma substance enrichment method and tea aroma substance prepared thereby

A technology of aroma substances and tea, which is applied in food science, application, food ingredients, etc., to achieve the effects of convenient operation, mild extraction conditions, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

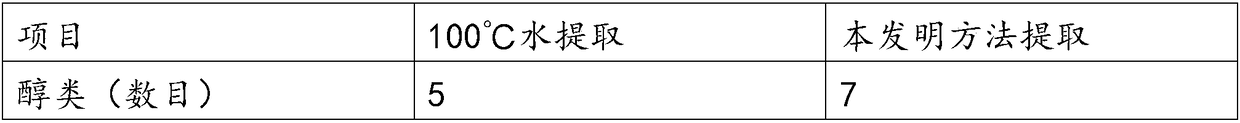

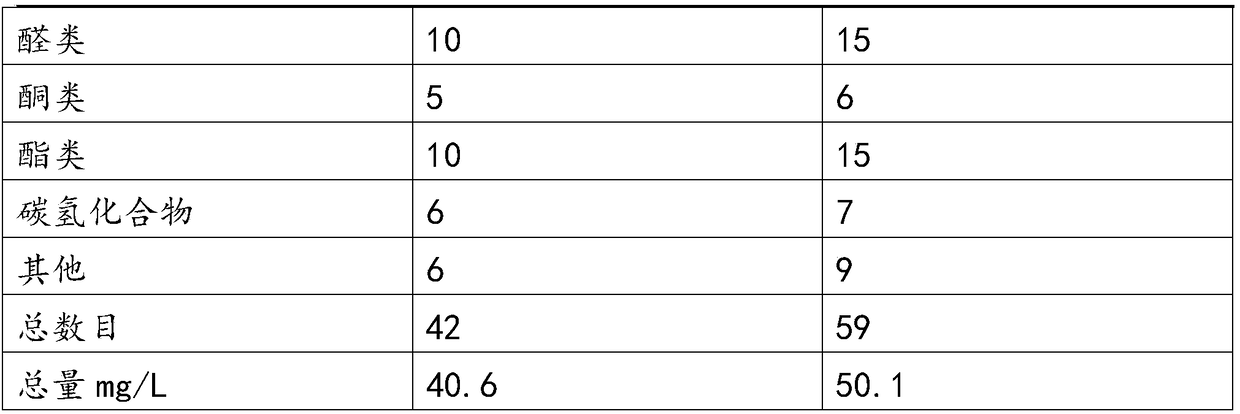

Embodiment 1

[0040] Mechanically pulverize Fenghuang Dancong tea flakes into 10-mesh tea powder, mix with 10% ethanol aqueous solution at a mass ratio of 1:20, extract at a constant temperature at 4°C for 5 hours, filter out tea residue, and obtain extract 1. Continue to add an aqueous ethanol solution with a volume concentration of 10% to the tea dregs at a mass ratio of 1:5, extract at a constant temperature at 20° C. for 2 h, filter out the tea dregs, and obtain extract 2. Add 10% ethanol aqueous solution with a volume concentration of 10% to the tea dregs again according to the mass ratio of 1:5, heat up to 40° C. and extract at a constant temperature for 30 min, filter out the tea dregs, and obtain extract 3. The extracts 1, 2 and 3 were cooled to room temperature and mixed, and then connected to the laboratory circulating vacuum pervaporation system (manufactured by Hangzhou Rena Membrane Engineering Co., Ltd.), and the aroma substances were enriched in circulation at 20°C at low temp...

Embodiment 2

[0044] Luzhou-flavor Tieguanyin tea leaves were mechanically crushed into 10-mesh tea powder, mixed with 20% ethanol aqueous solution at a mass ratio of 1:20, extracted at a constant temperature of 10°C for 6 hours, and the tea residue was filtered to obtain extract 1. Continue to add an aqueous ethanol solution with a volume concentration of 20% to the tea dregs at a mass ratio of 1:10, extract at a constant temperature at 25° C. for 6 h, filter out the tea dregs, and obtain extract 2. Add 20% ethanol aqueous solution to the tea dregs at a mass ratio of 1:5 again, heat up to 40° C. and extract at a constant temperature for 1 h, filter out the tea dregs, and obtain extract 3. Cool the extracts 1, 2 and 3 to room temperature and mix them, and then connect them to the laboratory circulating vacuum pervaporation system (manufactured by Hangzhou Rena Membrane Engineering Co., Ltd.). Concentrate solution 1; then heat up to 60°C to enrich high-boiling point aroma substances, and col...

Embodiment 3

[0048] Mechanically pulverize yellow tea into 20-mesh tea powder, mix it with 30% ethanol aqueous solution at a mass ratio of 1:15, extract at a constant temperature of 10°C for 4 hours, filter out the tea leaves, and obtain extract 1. Continue to add an aqueous ethanol solution with a volume concentration of 30% to the tea leaves at a mass ratio of 1:10, extract at a constant temperature at 30°C for 6 hours, filter out the tea leaves, and obtain an extract 2. Add 30% ethanol aqueous solution to the tea dregs at a mass ratio of 1:5 again, heat up to 60° C. and extract at a constant temperature for 1 h, filter out the tea dregs, and obtain extract 3. Cool the extracts 1, 2 and 3 to room temperature and mix them, and then connect them to the laboratory circulating vacuum pervaporation system (manufactured by Hangzhou Rena Membrane Engineering Co., Ltd.). Enrich liquid 1; then raise the temperature to 60°C to enrich high-boiling point aroma substances, and collect enriched liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com