Preparation method of Ti/Al3Ti layered composite material

A layered composite material and composite plate technology, which is applied in the field of composite material preparation, can solve the problems of easy occurrence of cracks, low efficiency, weakened friction effect on the surface of materials, etc., so as to improve the interface bonding quality, improve the reaction efficiency, and improve the bonding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

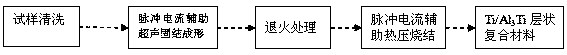

[0023] Such as figure 1 Show, a kind of preparation method of Ti / Ai3Ti layered composite material, comprise the following steps, the first step, sample cleaning, sample cleaning step is to select titanium or aluminum foil material as raw material, at first foil material is cleaned, removes surface stain, Clean the foil with acetone and then alcohol.

[0024] The second step is pulse current assisted ultrasonic consolidation forming. The pulse current assisted ultrasonic consolidation forming step is to make the original plate with a thickness of 0.1-0.2 mm according to Ti-Al-Ti-Al...Ti or Al-Ti-Al-Ti... ...The sequence of Al is superimposed one by one by ultrasonic consolidation. The ultrasonic consolidation process is to fix the aluminum foil on the ultrasonic consolidation forming equipment and set the ultrasonic consolidation parameters as speed 5~30mm / s, amplitude 15~30μm, The pressure is 0.5~3kN, the titanium foil is consolidated on the aluminum foil and the ultrasonic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com