Method and system for deeply treating leachate

An advanced treatment and leachate technology, applied in the field of leachate treatment, can solve the problems of poor leachate treatment effect, difficult management and storage, complex leachate components, etc., to achieve comprehensive treatment, easy operation and high impact load resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

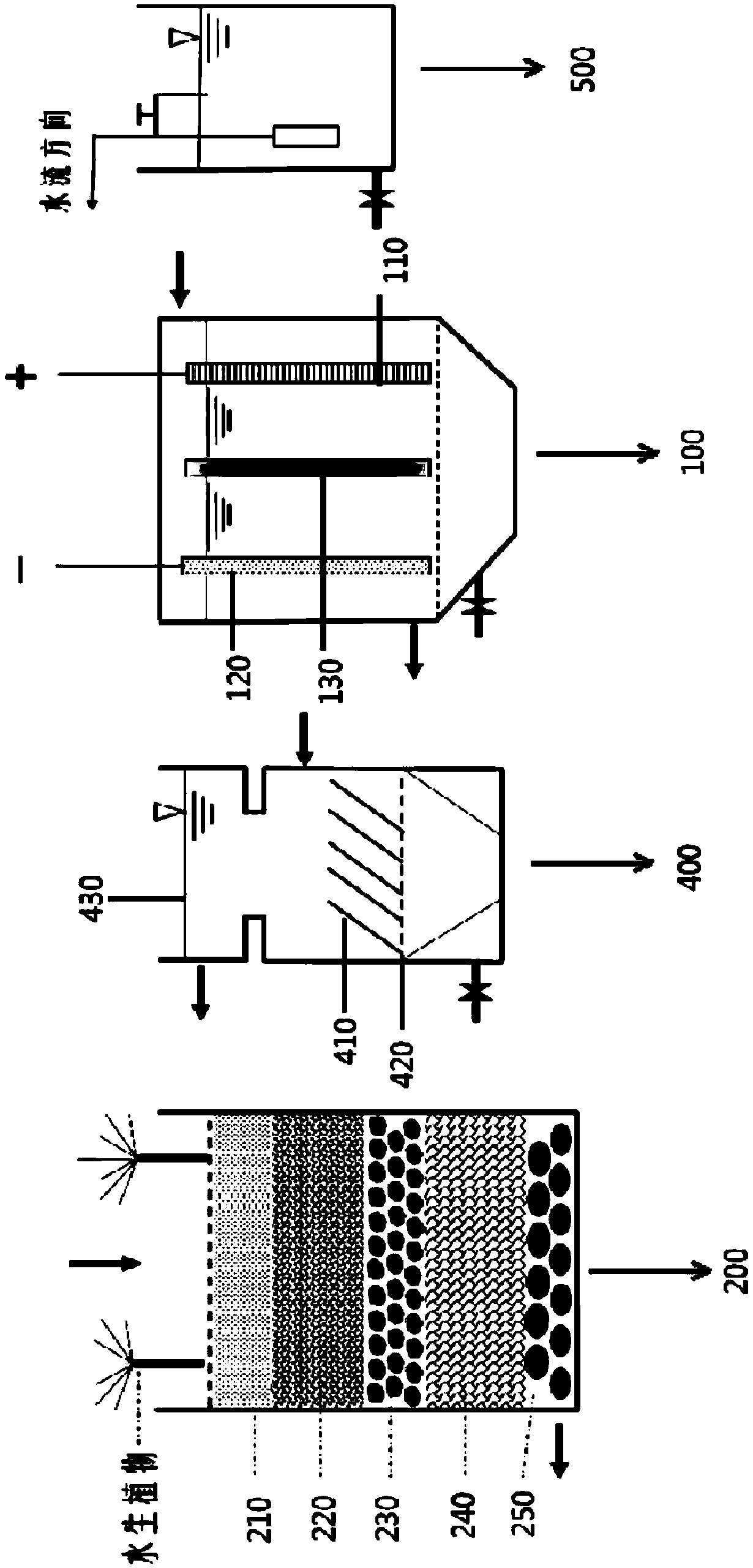

[0181] A method for advanced treatment of leachate, liquid treatment of leachate by such as figure 1 The system implementation shown.

[0182] The leachate to be treated is prepared in the leachate distribution tank 500, and then passed into the electrolytic cell 100 for electrochemical treatment; solid-liquid separation is performed on the flocculated turbid liquid after electrochemical treatment, and the flocculated suspended matter is discharged; solid-liquid separation The final effluent is passed into the wetland purification device 200, and the leachate pollutants are degraded or removed through the laid packing layer, such as the fixation and removal of nitrogen, phosphorus and heavy metals, the degradation of refractory pollutants, and finally effluent.

[0183] The electrolytic cell 100 is composed of anode Ti / Pt / SbO 2 -Sb 2 o 4 , cathode graphite carbon felt and iron amphoteric electrode, the anode 110, cathode 120 and amphoteric electrode 130 are flat electrodes,...

Embodiment 2

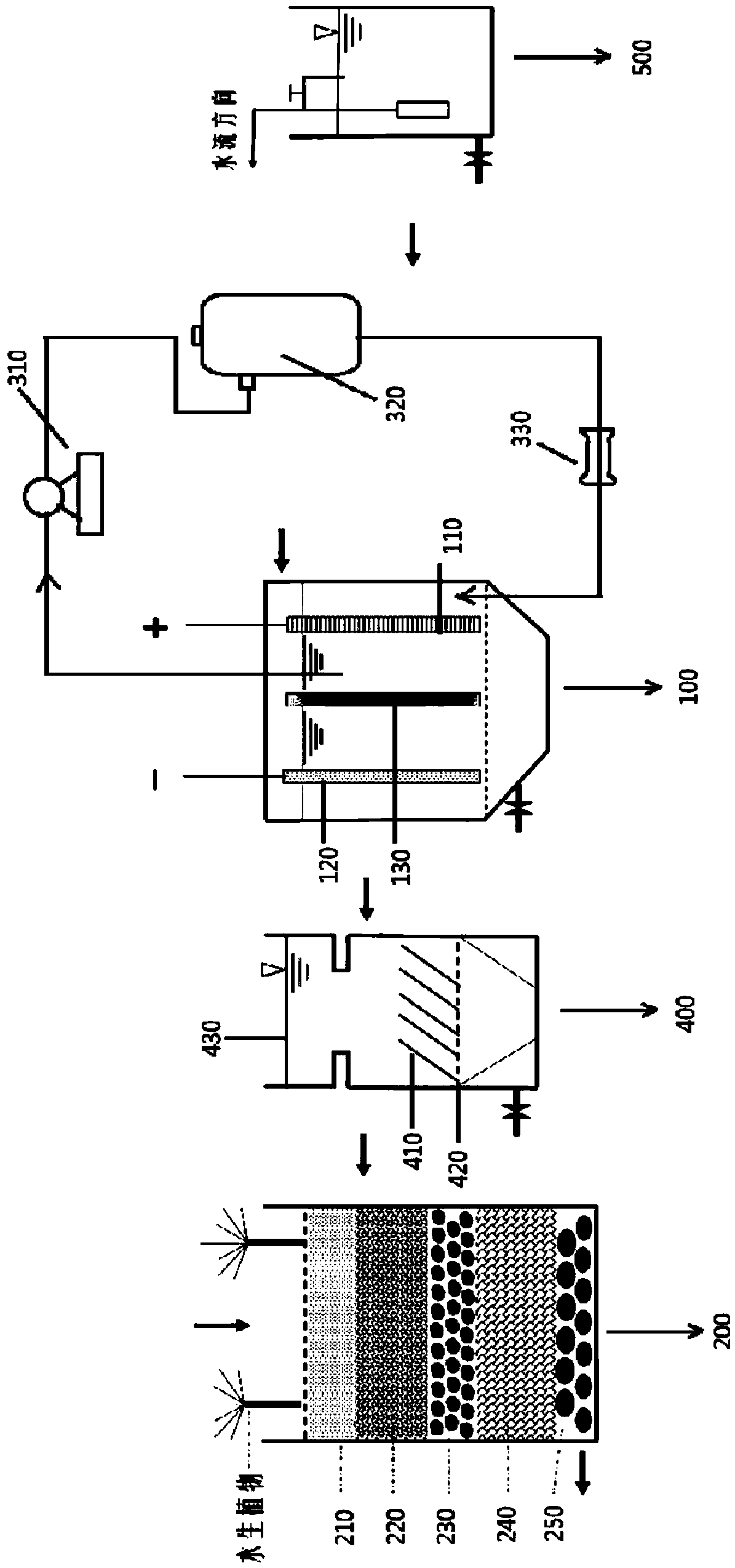

[0188] A method for advanced treatment of leachate, leachate liquid treatment through such as figure 2 The system implementation shown.

[0189] The leachate to be treated is prepared in the leachate distribution tank 500, and then passed into the electrolytic cell 100 for electrochemical treatment; solid-liquid separation is performed on the flocculated turbid liquid after electrochemical treatment, and the flocculated suspended matter is discharged; solid-liquid separation The final effluent is passed into the wetland purification device 200, and the leachate pollutants are degraded or removed through the laid packing layer, such as the fixation and removal of nitrogen, phosphorus and heavy metals, the degradation of refractory pollutants, and finally effluent.

[0190] The electrolytic cell 100 consists of anode Ti / IrO 2 / RuO 2 , the cathode graphite carbon blanket and the iron amphoteric electrode, the anode 110, the cathode 120 and the amphoteric electrode 130 are flat...

Embodiment 3

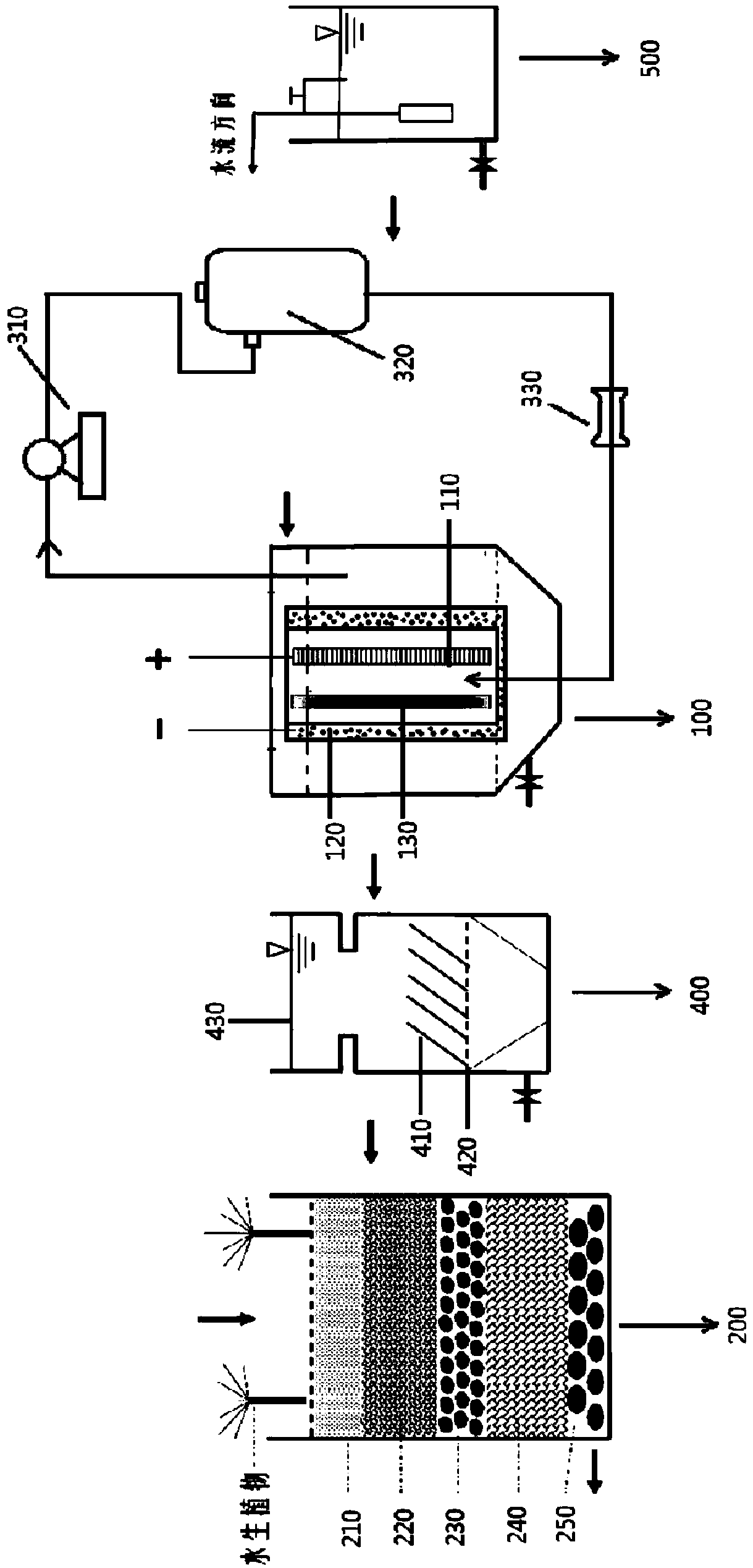

[0196] A method for advanced treatment of leachate, leachate liquid treatment through such as image 3 The system implementation shown.

[0197] The leachate to be treated is prepared in the leachate distribution tank 500, and then passed into the electrolytic cell 100 for electrochemical treatment; solid-liquid separation is performed on the flocculated turbid liquid after electrochemical treatment, and the flocculated suspended matter is discharged; solid-liquid separation The final effluent is passed into the wetland purification device 200, and the leachate pollutants are degraded or removed through the laid packing layer, such as the fixation and removal of nitrogen, phosphorus and heavy metals, the degradation of refractory pollutants, and finally effluent.

[0198] The electrolytic cell 100 electrolytic cell is composed of anode Ti / IrO 2 / RuO 2 , cathode activated carbon fiber electrode and aluminum amphoteric electrode. The cathode 120 is a closed screen tube with mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com