Pharmacy wastewater salt-dividing processing method

A pharmaceutical wastewater treatment method technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Taking a company's reclaimed water reuse build-operate-transfer (BOT) project as an example, the company's daily production of pharmaceutical wastewater is 12,000m 3 / d. Before the technology of the present invention was adopted, the pharmaceutical wastewater was directly treated by the company's sewage treatment system, and the obtained primary effluent directly entered the mechanical vapor recompression system (MVR for short) for evaporation and crystallization. Due to the high COD, high content of suspended matter and high hardness in the wastewater, the MVR needs to be cleaned frequently, resulting in the processing capacity of the entire MVR system not reaching 80% of the design capacity, and the energy consumption is extremely high.

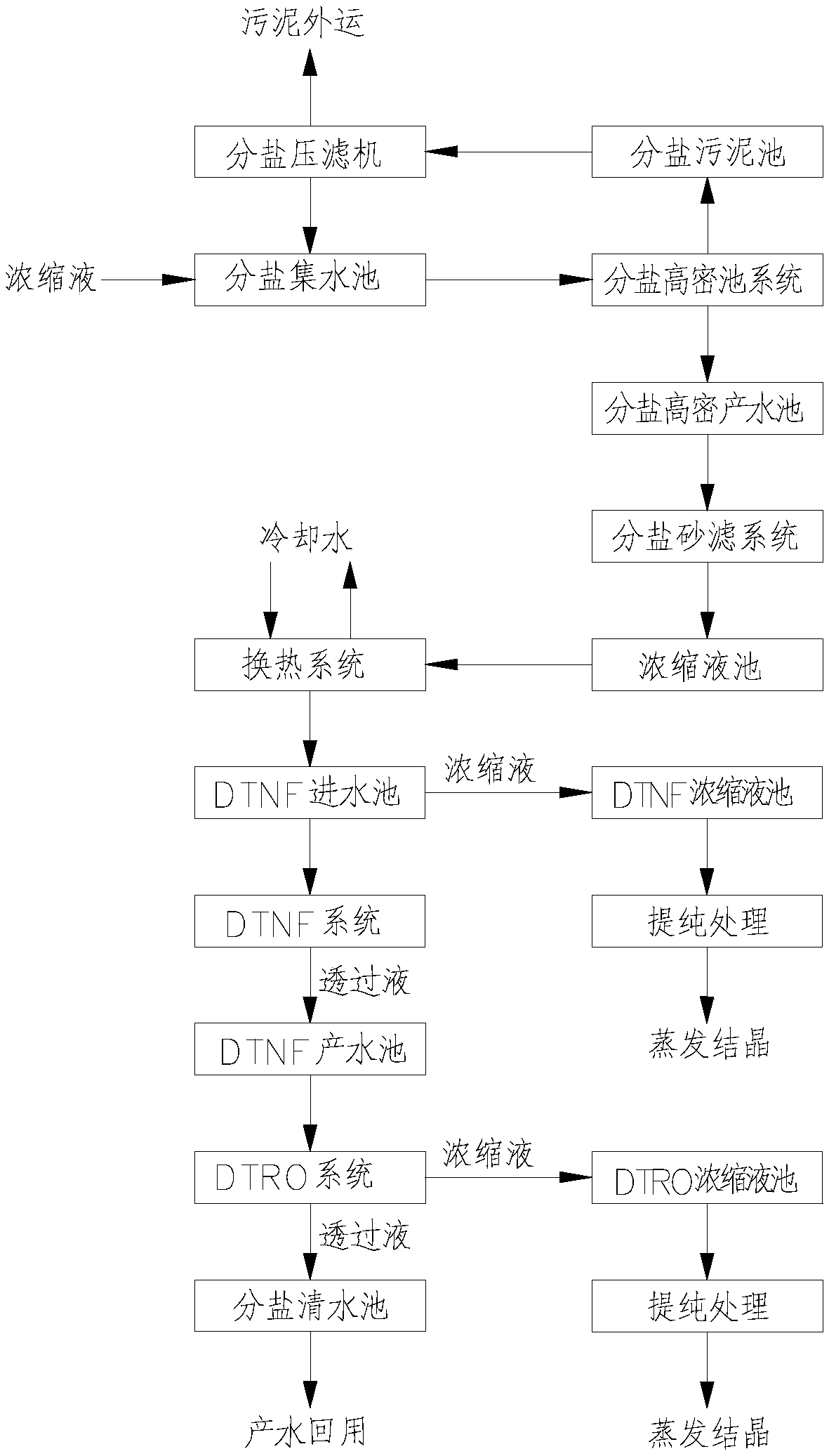

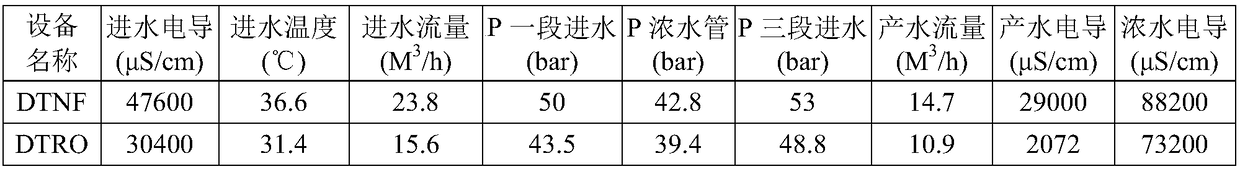

[0059] After adopting the process of the present invention, the concentrated solution of the membrane system enters the salt separation system after being pretreated, and the NaCl and NaCl in the waste water are realized 2 SO 4 Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com