Device for comprehensive treatment and utilization of livestock and poultry manure

A comprehensive treatment, livestock and poultry manure technology, applied in the field of energy-saving and environmental protection technology and equipment, can solve the problems of toxic and harmful products, flammable and explosive, and the turbidity of the sterilization effect biogas slurry is greatly affected, so as to improve the efficiency of enterprises and eliminate pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

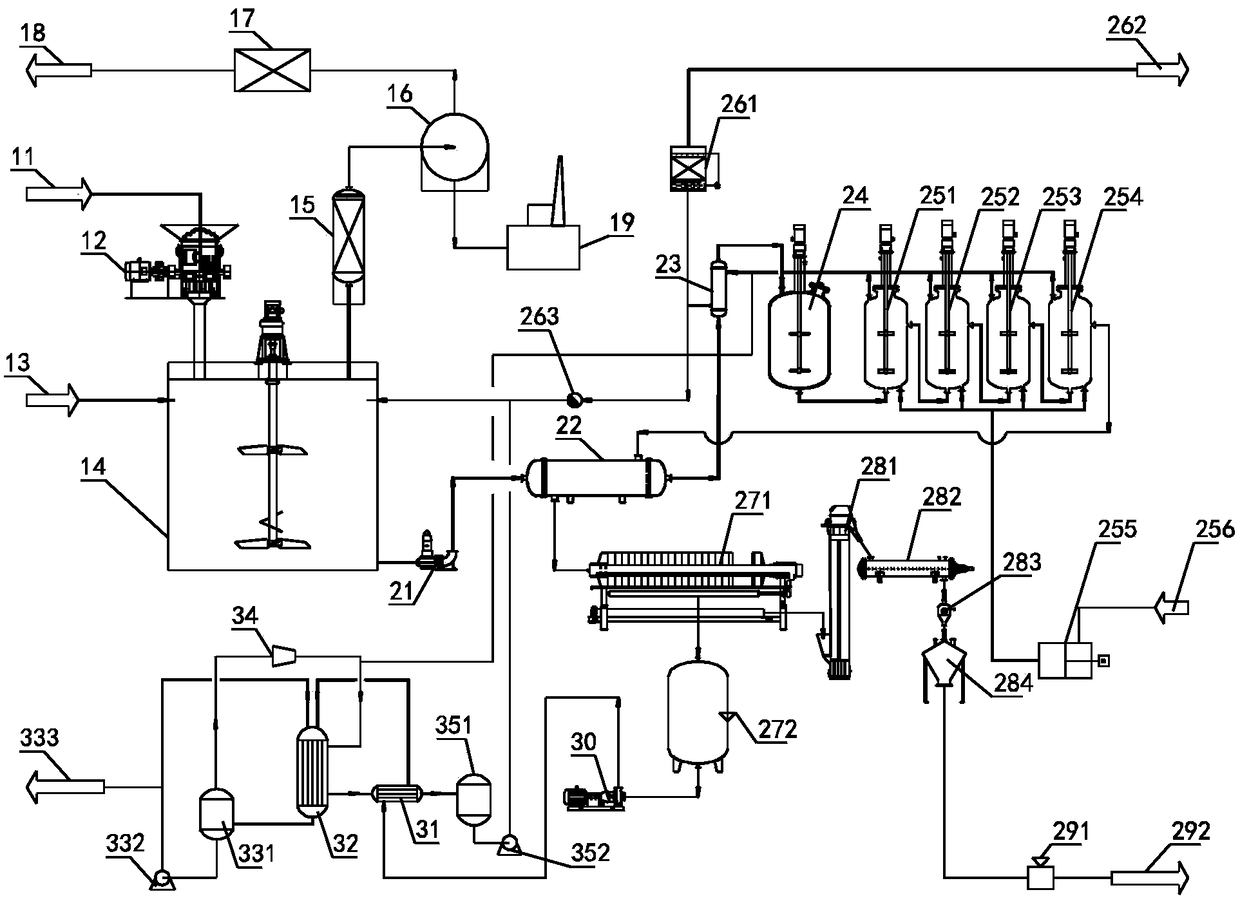

[0022] The present invention is clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings:

[0023] Such as figure 1 As shown, after the organic solid waste 11 is pulverized by the pulverizer 12, the waste water 13, the drain valve 263 and the condensate of the condensate pump 352 enter the anaerobic fermentation tank 14 for anaerobic fermentation. Oxygen fermentation produces biogas, and the generated biogas is desulfurized by the biogas desulfurization tower 15 and then enters the gas storage tank 16, and is purified by the biogas purification unit 17 to obtain the purified natural gas 18. The biogas in the gas storage tank 16 generates electrical energy through the biogas generating unit 19 .

[0024] Such as figure 1 As shown, the biogas residue and biogas slurry is transported to the heat exchangers 22 to 23 by the biogas residue and biogas slurry delivery pump 21 for heat exchange and then enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com