Hot-melt adhesive containing waste shellac residue and EVA and preparation method thereof

A hot-melt adhesive and shellac technology, which is applied in adhesives, natural resin chemical modification, adhesive additives, etc., can solve the problems of shellac processing enterprises' comprehensive benefits, resource waste, etc., achieve low softening point and enhance compatibility , the effect of high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A hot-melt adhesive containing shellac waste residue glue and EVA, comprising: 10 parts by weight of dehydrated shellac waste residue glue, 85 parts by weight of EVA 625, 15 parts by weight of EVOH-01 (degree of hydrolysis 15.3%) obtained by hydrolysis of EVA760, 4 parts by weight of polymerized rosin glycidyl ester (PRG), 10 parts by weight of rosin glycidyl ester (RG), the composite tackifier is 10% of the sum of (EVA+EVOH) quality, and 1250 mesh light calcium carbonate is reactive co- 8% of the total mass of the mixture, 58 # The paraffin wax is 3% of the total mass of the reactive blend, and the antioxidant 1010 is 0.2% of the total mass of the reactive blend. Wherein, the composite tackifier is a mixture of C9 petroleum resin, terpene phenolic resin and rosin glyceride with a mass ratio of 1:0.8:0.5.

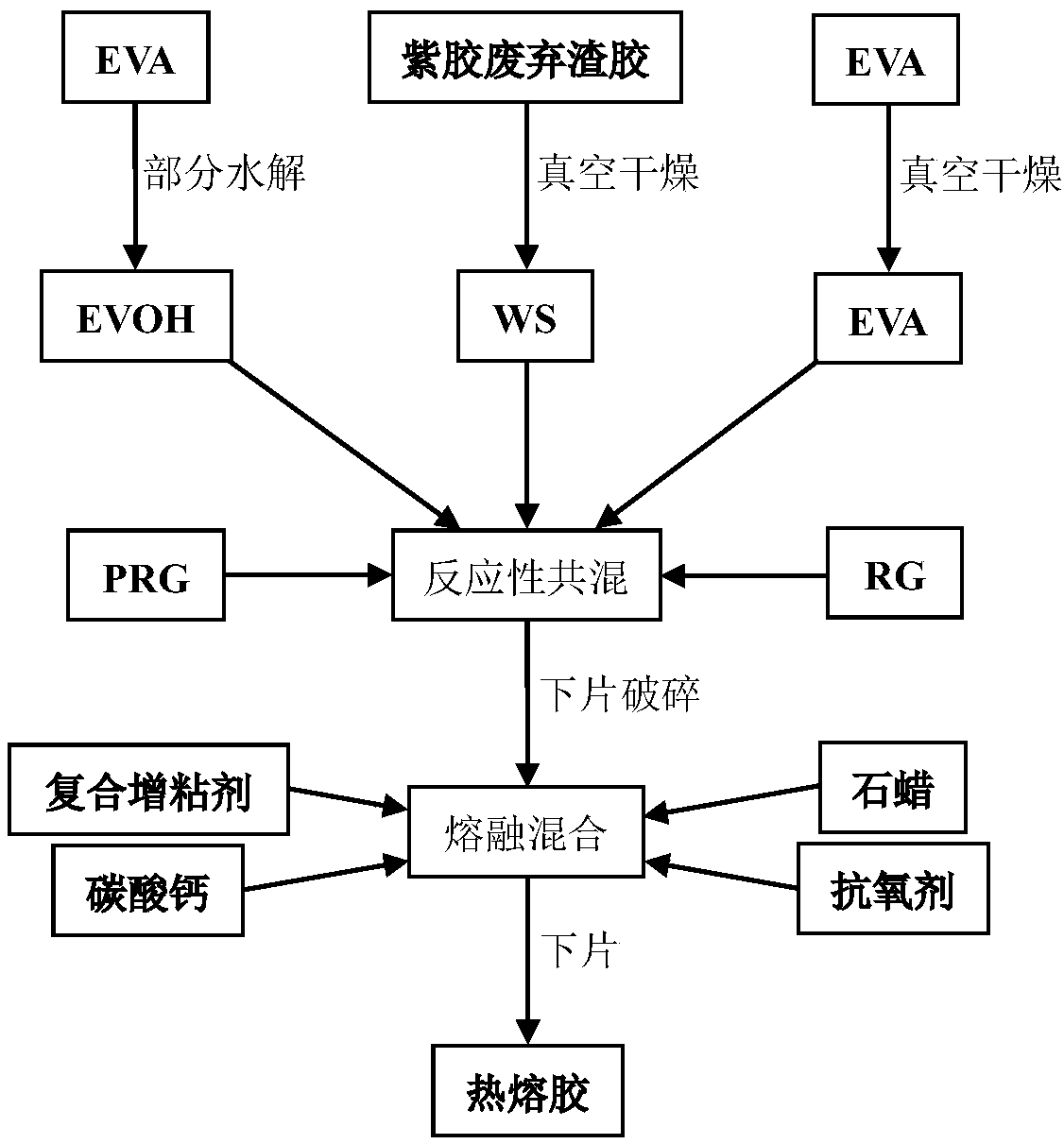

[0050] The preparation process is as figure 1 As shown, the specific operation steps are as follows:

[0051] (1) Preparation of dehydrated lac waste residue glue...

Embodiment 2

[0061] A hot-melt adhesive containing shellac waste residue glue and EVA, comprising: 15 parts by weight of dehydrated shellac waste residue glue, 63388 parts by weight of EVA, and 12 parts by weight of EVOH-02 (hydrolysis degree 27.5%) obtained by hydrolysis of EVA 40W , 6 parts by weight of polymerized rosin glycidyl ester, 8 parts by weight of rosin glycidyl ester, the composite tackifier is 15% of the sum of (EVA+EVOH) quality, calcium carbonate is 10% of the total mass of the reactive blend, paraffin wax It is 5% of the total mass of the reactive blend, and the antioxidant is 0.5% of the total mass of the reactive blend. Wherein, the composite tackifier is a mixture of C9 petroleum resin, terpene phenolic resin and rosin glyceride with a mass ratio of 1:1:1.

[0062] The preparation process is as figure 1 Shown, concrete operation step is roughly the same as embodiment 1, and difference is:

[0063] In step (1), vacuum drying at 78° C. for 12 hours;

[0064] EVA 760 in...

Embodiment 3

[0069] A hot-melt adhesive containing shellac waste residue glue and EVA, comprising: 25 parts by weight of dehydrated shellac waste residue glue, 71092 parts by weight of EVA, and 8 parts by weight of EVOH-03 (degree of hydrolysis 34.9%) obtained by hydrolysis of EVA UL04533CC , 8 parts by weight of polymerized rosin glycidyl ester, 6 parts by weight of rosin glycidyl ester, the composite tackifier is 25% of the sum of (EVA+EVOH) quality, calcium carbonate is 12% of the total mass of the reactive blend, paraffin wax It is 7% of the total mass of the reactive blend, and the antioxidant is 0.8% of the total mass of the reactive blend. Wherein, the composite tackifier is a mixture of C9 petroleum resin, terpene phenolic resin and rosin glyceride with a mass ratio of 1:1.2:1.

[0070] The preparation process is as figure 1 Shown, concrete operation step is roughly the same as embodiment 1, and difference is:

[0071] In step (1), vacuum drying at 70° C. for 16 hours;

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com