Saccharomyces cerevisiae strain, method and application for producing high nucleic acid yeast

A technology for Saccharomyces cerevisiae and nucleic acid yeast, which is applied in microorganism-based methods, biochemical equipment and methods, and medical preparations containing active ingredients, etc., can solve the problem of low nucleic acid content, increase production costs, and cannot meet large-scale industrial production. and other problems, to achieve the effect of increasing nucleic acid content and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Fermentation production of high nucleic acid yeast

[0062] The invention provides a method for producing yeast by utilizing Saccharomyces cerevisiae yeast strain d8.8, comprising the following steps:

[0063] The Saccharomyces cerevisiae d8.8 (Saccharomyces cerevisiae d8.8) strain was used and preserved in the China Center for Type Culture Collection (CCTCC) with the preservation number CCTCC M2017148. Observed by an optical microscope, the cell diameter of the Saccharomyces cerevisiae strain is about 4-6 μm, presents an ellipsoid, and reproduces asexually by budding; after being cultured on a solid medium plate at 28°C for 24 hours, it becomes a milky white, opaque, round colony.

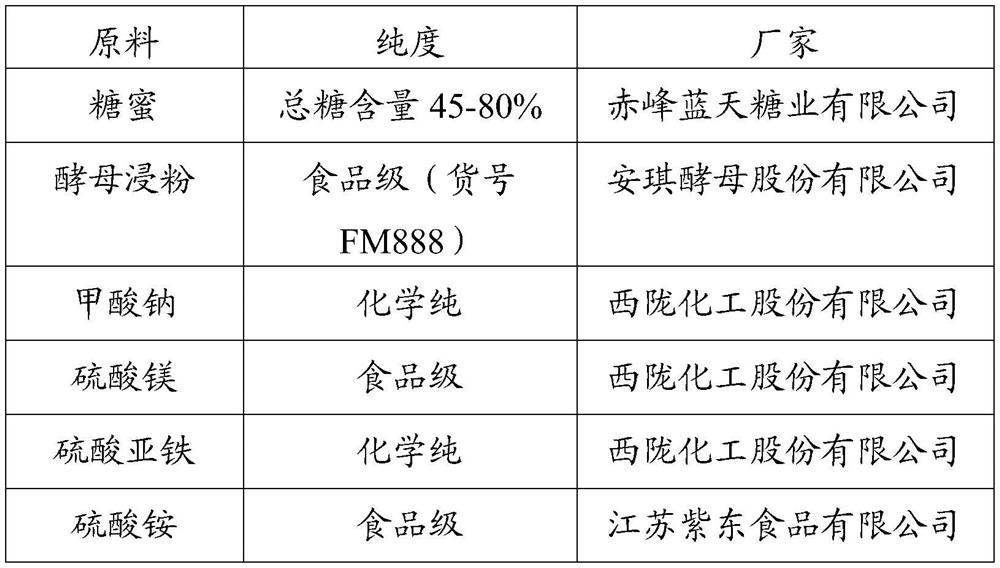

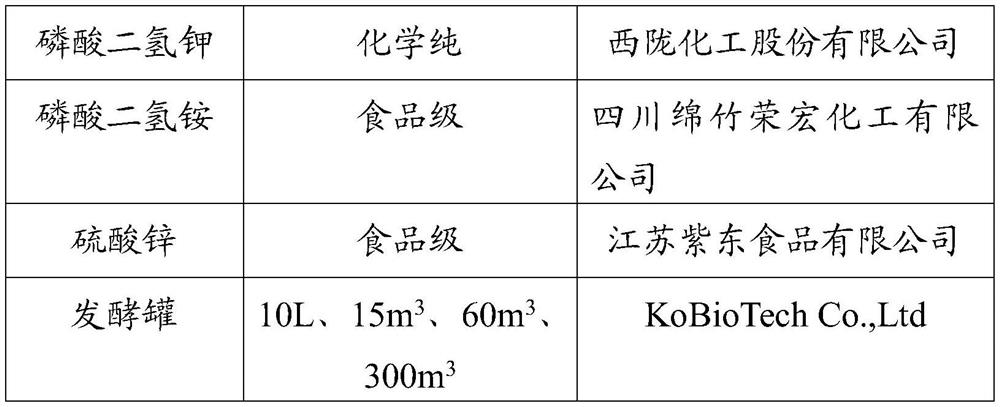

[0064] After being activated by using the described bacterial strains, culture in 250mL shake flasks, 10L small tanks, 15mL 3 Fermentation tank culture, 60m 3 First-class seed fermentation tank cultivation, 300m 3 Secondary seed fermenter cultivation and 300m 3 Commercial fermentati...

Embodiment 2

[0126] (1) Preparation of high nucleic acid yeast

[0127] The following method is adopted for industrial production to obtain high nucleic acid yeast.

[0128] (1) The culture steps of 250mL shake flask are as follows: the slant bacteria were inoculated into the 250mL shake flask, and cultured at 35°C for 20h.

[0129] Among them, the formula of 250mL medium is as follows: 20g of sucrose, 2g of potassium dihydrogen phosphate, 2g of magnesium sulfate, 1g of yeast extract powder and 100mL of sterile water, and adjust the pH value to 6.

[0130] (2) Cultivation in a 10L small tank is as follows: transfer the shake flask culture solution obtained in step (1) into a 10L small tank, and culture at a temperature of 35° C. with stirring at 20 r / min for 20 h to obtain a seed culture solution.

[0131] Among them, the formula of the 10-liter small tank medium is as follows: 1.5Kg of sucrose, 300g of yeast extract powder, 5g of potassium dihydrogen phosphate, 5g of magnesium sulfate an...

Embodiment 3

[0147] (1) Preparation of high nucleic acid yeast

[0148] The following method is adopted for industrial production to obtain high nucleic acid yeast.

[0149] (1) The culture steps of 250mL shake flask are as follows: the slant bacteria were inoculated into the 250mL shake flask, and cultured at 28°C for 30h.

[0150] Among them, the formula of 250mL medium is as follows: 5g of sucrose, 1g of potassium dihydrogen phosphate, 1g of magnesium sulfate, 3g of yeast extract powder and 100mL of sterile water, and adjust the pH value to 5.5.

[0151] (2) Cultivate in a 10L small tank as follows: transfer the shake flask culture solution obtained in step (1) into a 10L small tank, and culture at 28° C. with stirring at 15 r / min for 30 h to obtain a seed culture solution.

[0152] Among them, the formula of the 10-liter small tank medium is as follows: 375Kg of sucrose, 200g of yeast extract powder, 10g of potassium dihydrogen phosphate, 10g of magnesium sulfate and 7.5L of sterile w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com