Method for measuring phthalic anhydride transfer volume in food contact material and product

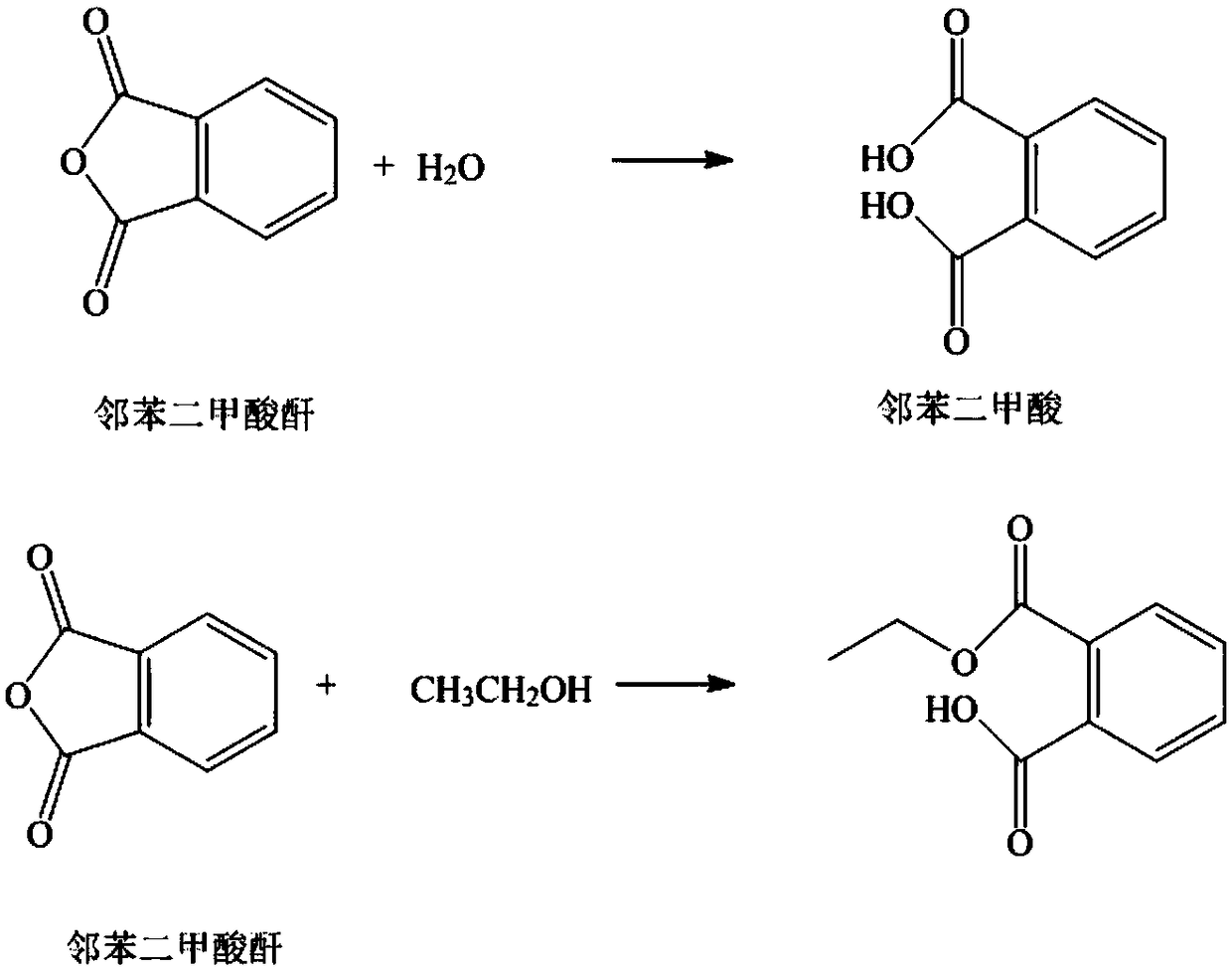

A technology for phthalic anhydride and food contact materials, which is applied in the field of measurement of the migration of phthalic anhydride in food contact materials and products, and can solve the impact of compliance evaluation of food contact materials and the actual value of test results is low and other problems, to achieve the effect of wide application range, strong practicability and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

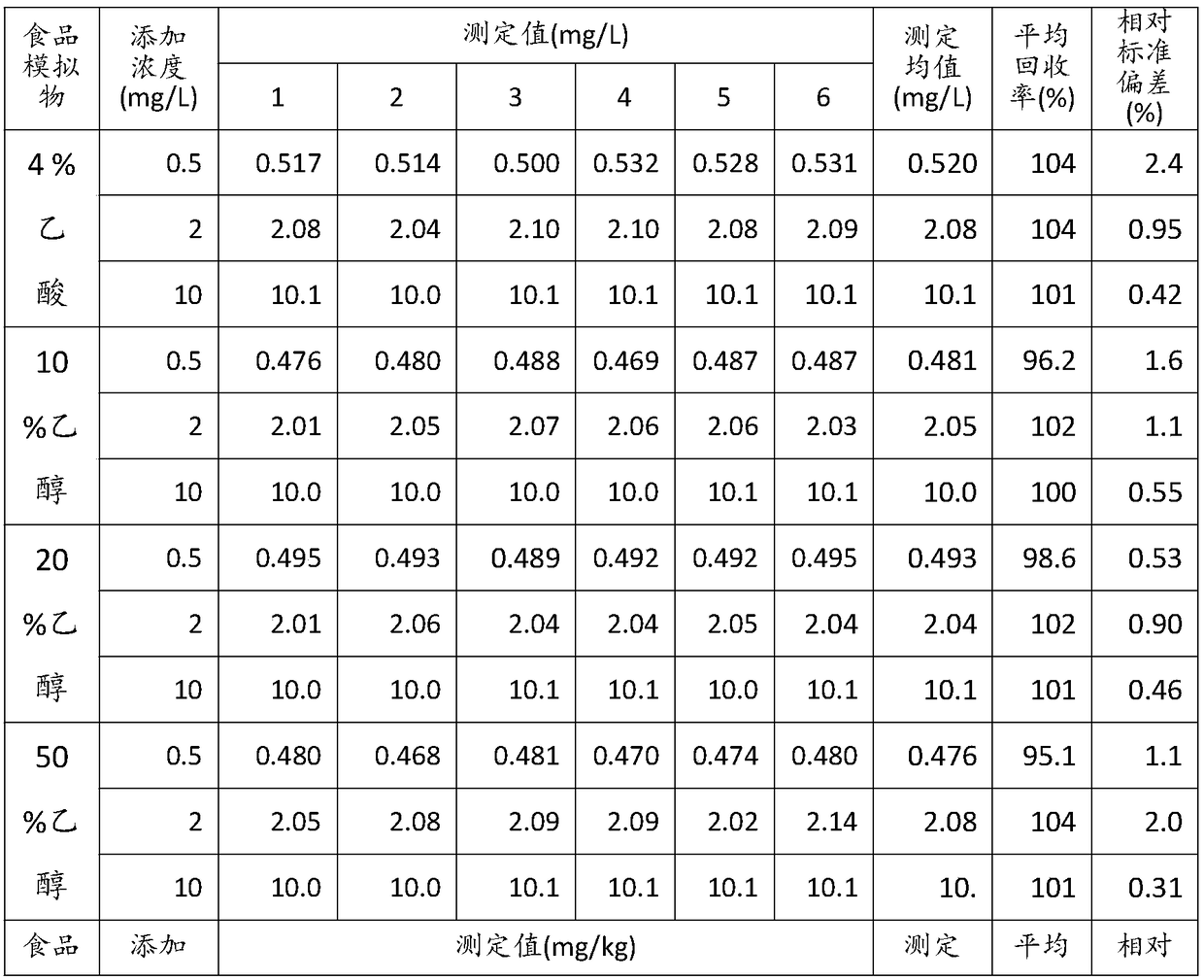

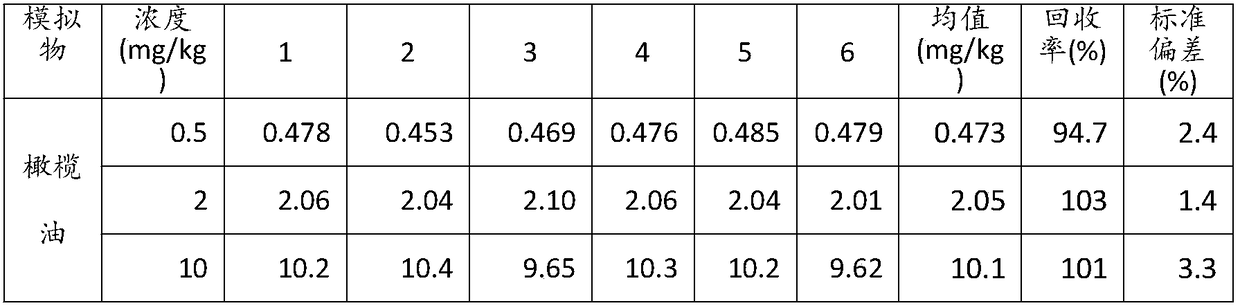

[0038] The food simulants involved in this embodiment are divided into two types: water-based and oil-based, wherein the water-based food simulants include the following four types: 4% volume fraction of acetic acid solution, 10% volume fraction of ethanol solution, 20% volume fraction ethanol solution and 50% ethanol solution by volume; the oil base is olive oil.

[0039] In the present embodiment, glacial acetic acid (C2H4O2), dehydrated alcohol (C2H6O), methyl alcohol (CH4O) are all analytically pure, olive oil is chemically pure, and water is the first-grade water that GB / T 6682 stipulates.

[0040] The instruments used include: 1. High-performance liquid chromatography: equipped with a diode array detector or an ultraviolet detector;

[0041] 2. Analytical balance: Sensitivity 0.1mg;

[0042] 3. Pure water meter;

[0043] 4. Microporous membrane: 0.22μm PTFE membrane;

[0044] 5. Pipettes: 100μL, 1000μL, and 5mL pipettes.

[0045] The method for determining the migrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com