A split composite bus bar suitable for diesel locomotive power module

A power module and composite busbar technology, which is applied in the output power conversion device, the conversion of AC power input to DC power output, electrical components, etc. Ensure safe and reliable work, facilitate repair and maintenance, reduce size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

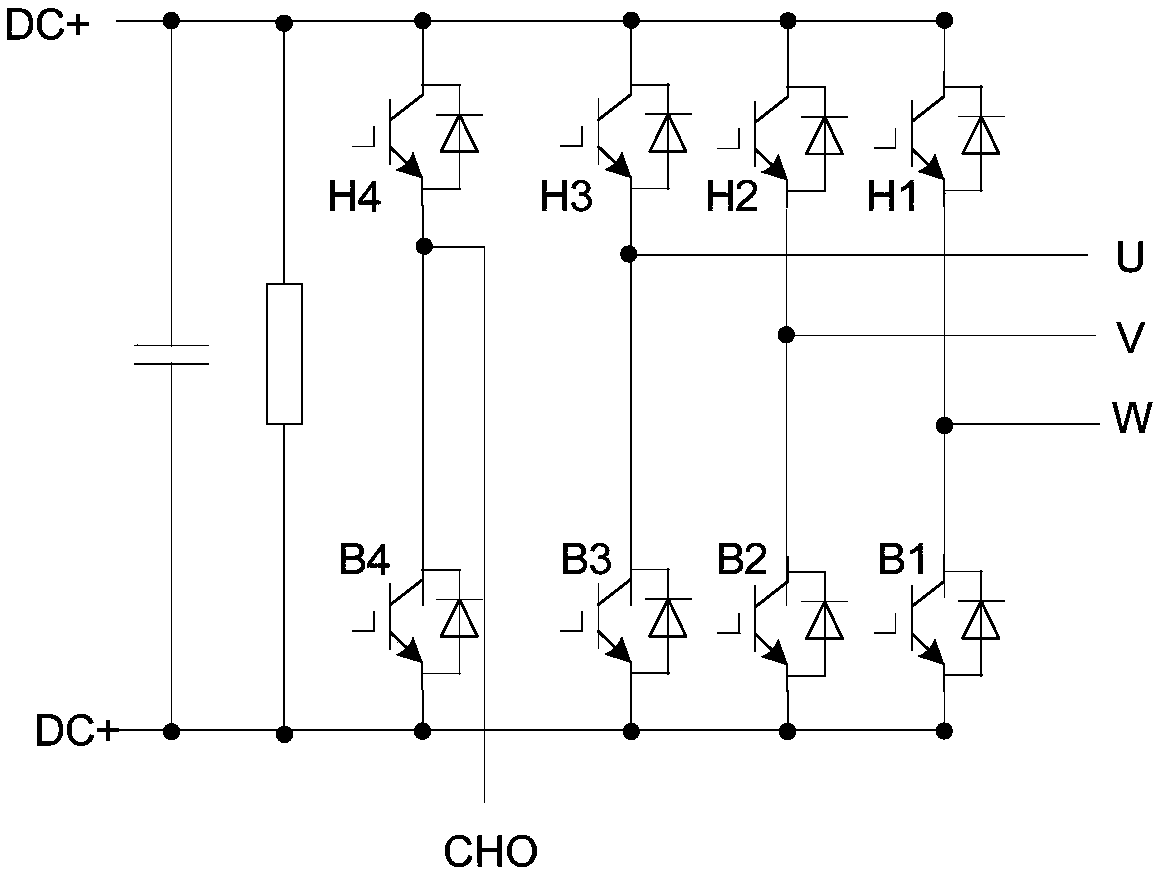

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

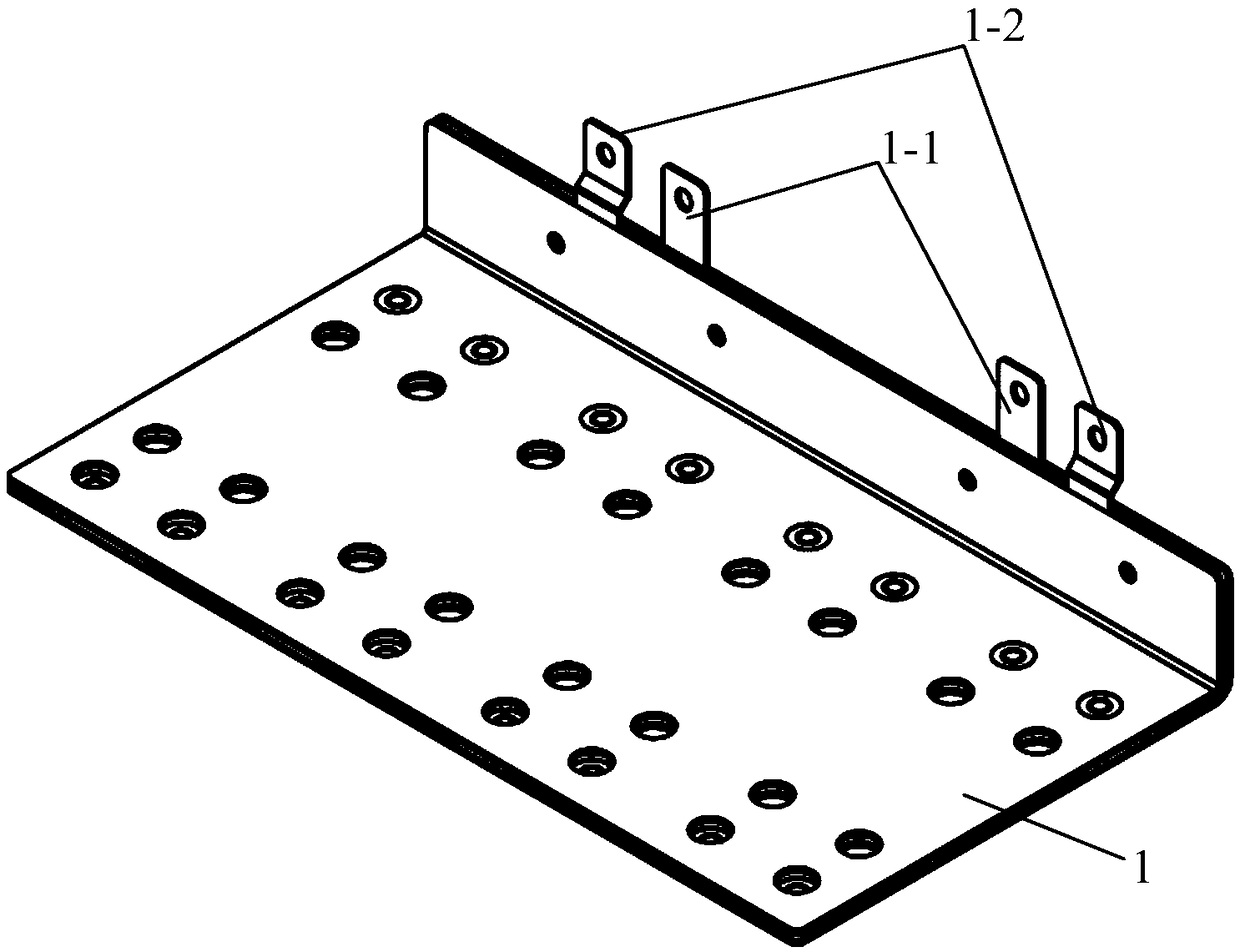

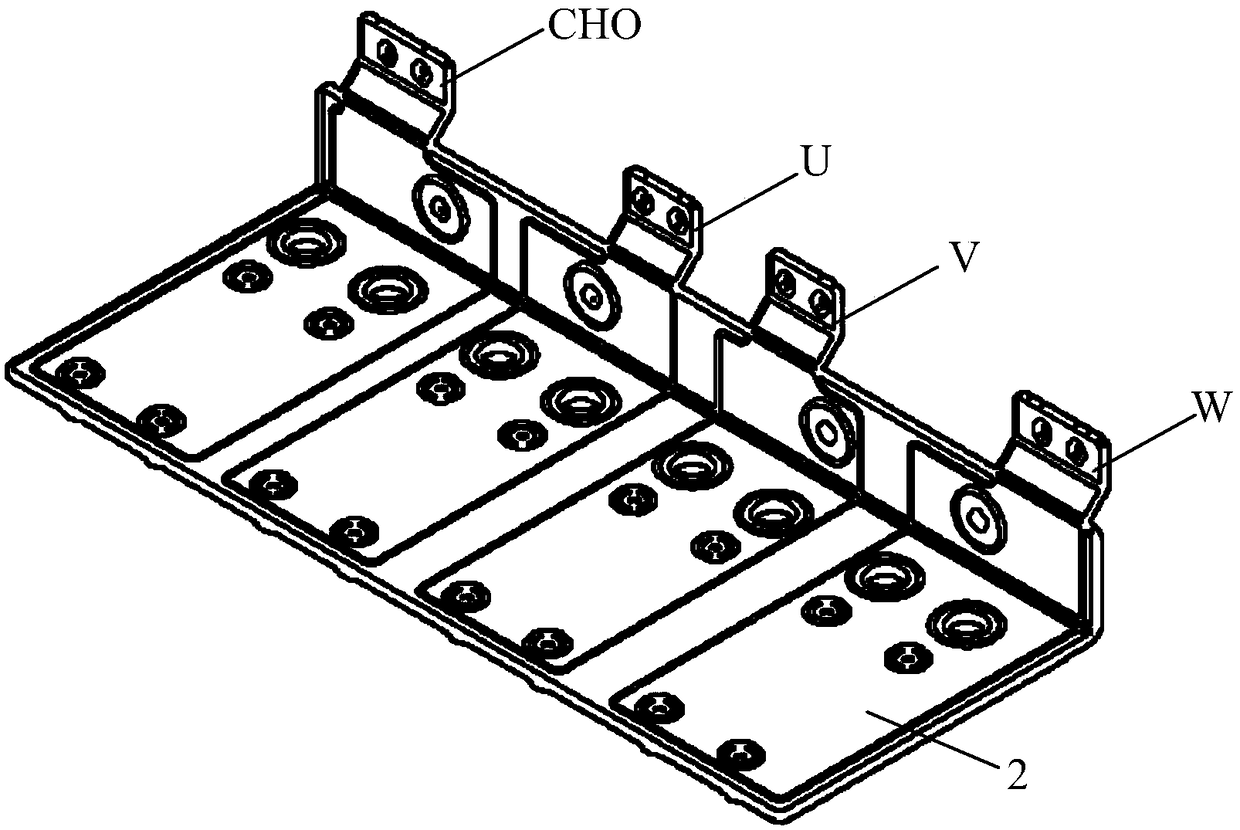

[0034] see figure 2 with image 3 , the present invention is applicable to the split composite busbar of the diesel locomotive power module, which is composed of a DC busbar 1 and an AC busbar 2, the DC busbar 1 and the AC busbar 2 adopt a split structure; the DC busbar 1 and the AC busbar 2 are flat structures, and a plurality of DC busbars 1 and AC busbars 2 are stacked on top of each other and installed together by supporting pads arranged on the DC busbars 1 or AC busbars 2 .

[0035] DC busbar 1 and AC busbar 2 are mainly made of polyvinyl fluoride PVF board.

[0036] The insulation method between the stacked busbars of the present invention is: insulation and isolation between the adjacent stacked DC busbars and AC busbars is carried out through air, or laminated plates are used between the conductive layers of the stacked busbars Insulate. And the laminate is a GPO-3 laminate.

[0037] One side of the DC busbar 1 is provided with a folded edge, and a positive termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com