Insecticidal composition containing afidopyropen and cycloxaprid

A technology of dipropacyclopyrene and insecticidal composition, which is applied in the field of pesticide application to achieve the effects of reducing impact, overcoming disease resistance and improving control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment one: Indoor toxicity embodiment

[0019] The test refers to the "Guidelines for Indoor Bioassays of Pesticides", and the indoor toxicity test is used to illustrate whether the combination of dipropacyclopyrid and cyclopyrid has a synergistic effect on aphids and whitefly.

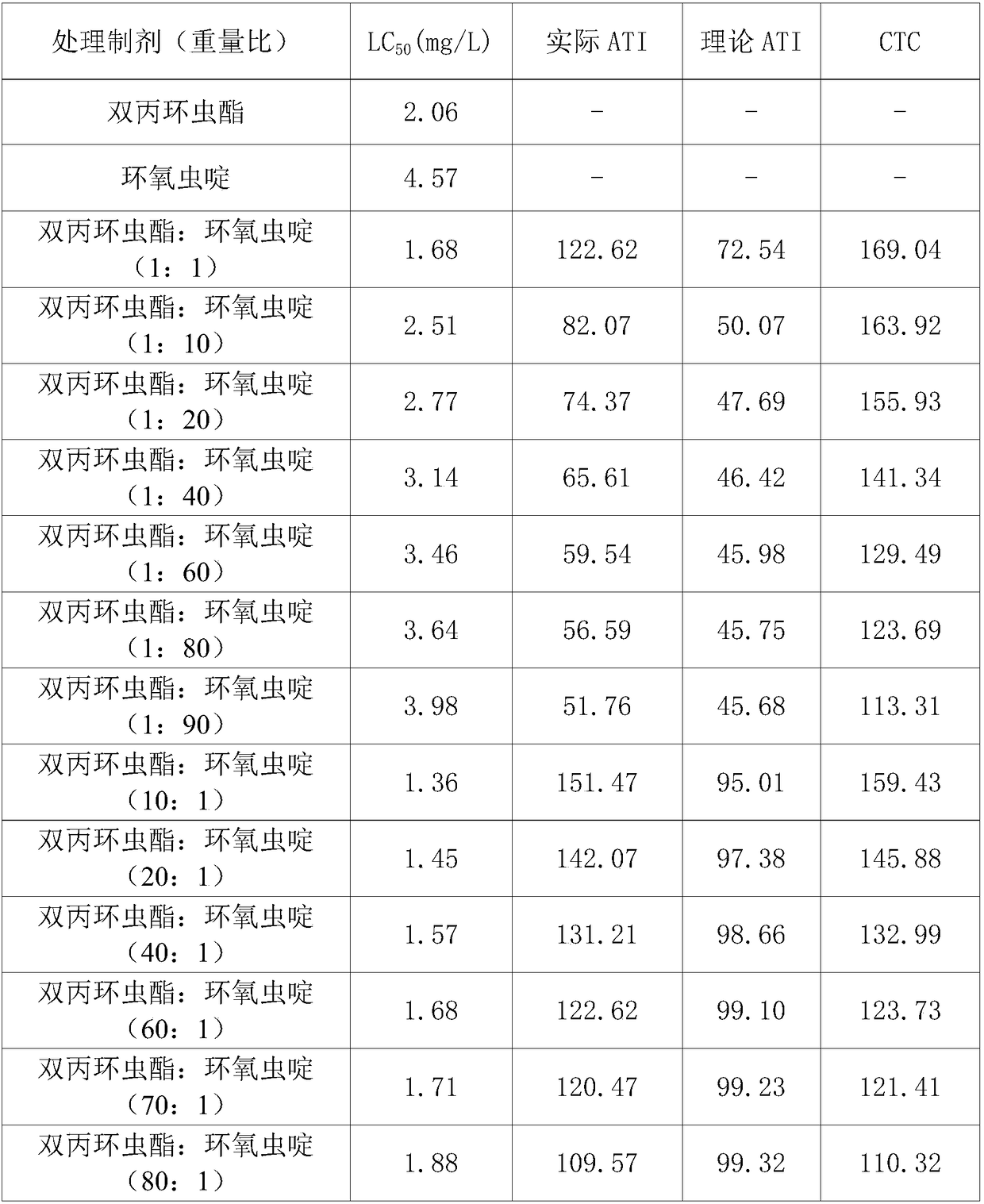

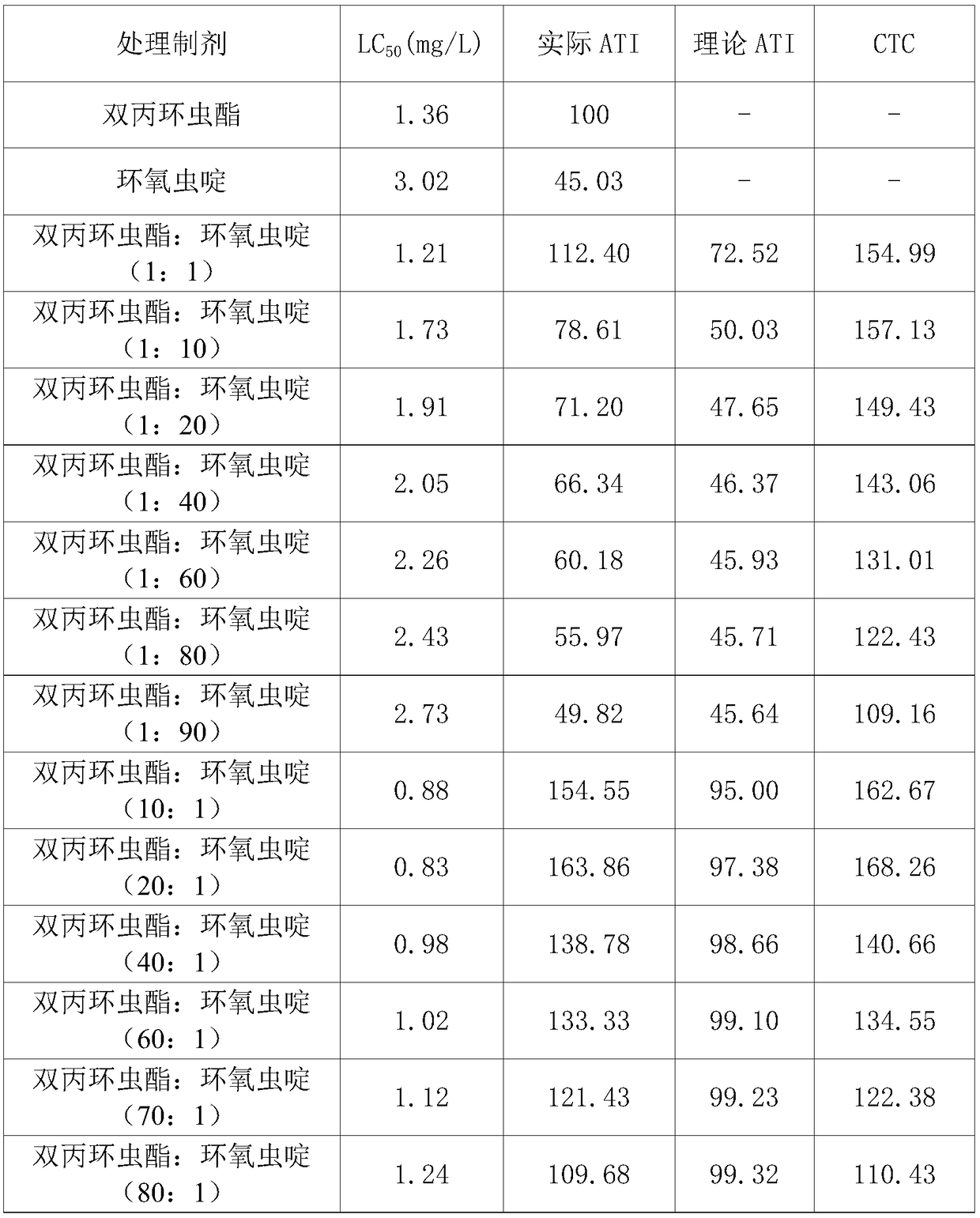

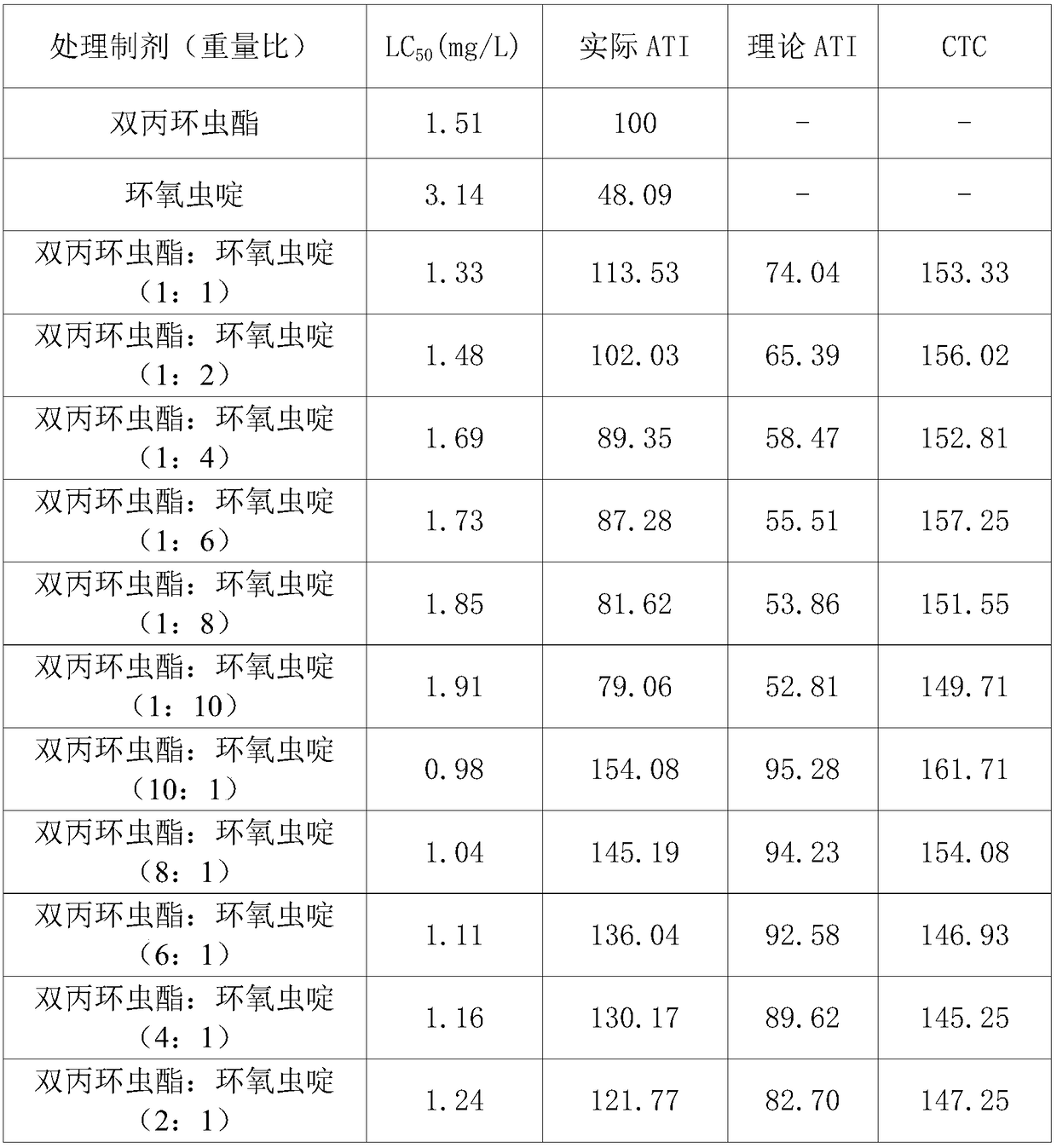

[0020] (1) Combined toxicity test to aphids

[0021] Indoor virulence assay was carried out by soaking insects. Dipropacyclopyrene and cyclopyrid primary drugs were configured into 5 serial concentrations of liquid medicines for future use.

[0022] Select the nymphs of green peach aphid (Myzuspersicae) cultivated in the room and of the same age. After immersing the target insects in the liquid medicine for 10 seconds, absorb the excess liquid medicine with filter paper, transfer the test insects to rearing under normal conditions, and repeat each treatment 4 times. 10 insects, treated with clean water as a control. After 24 hours, check the number of dead and alive insects, and the tes...

Embodiment 2

[0044] Embodiment two: preparation formula embodiment

[0045] (1) 15% Dipropterpirate · Cyclopyrid Water Dispersible Granules

[0046]3% dipropetal, 12% cyclopyrid, 3% GY-D06, 4% sodium lignosulfonate, 3% pull open powder BX (sodium dibutylnaphthalene sulfonate), 4% K-12 (Sodium Lauryl Sulfate), Light Calcium is added to 100% parts by weight. The above-mentioned raw materials are prepared through the conventional method for preparing water-dispersible granules, that is, the steps of mixing ultrafine airflow pulverization, mixing, and granulating to prepare 15% dipropacyclopyrene-epoxyclomid water-dispersible granules.

[0047] (2) 35% dipropteraprene · cyclopyrid wettable powder

[0048] Weigh 10% dipropetal, 25% cyclopyrid, 5% calcium alkylphenol polyoxyethylene ether sulfonate, 8% alkylinhibition sulfonate formaldehyde condensate, 3% alkyl tea sulfonic acid Sodium and talcum powder are added up to 100% by weight. The above-mentioned raw materials are mixed, pulverized b...

Embodiment 3

[0057] Embodiment three: field use effect embodiment

[0058] Field efficacy tests of dipropyrene and cyclopyrid against bemisia tabaci and cabbage aphids.

[0059] Spraying is applied during the peak period of target pest damage. 20% dipropacyclopyrene suspension concentrate and 10% cyclopyrid water-dispersible granule were used as control agents. There were 9 drug treatments and 1 blank control area in the test, and each treatment was repeated 3 times. Before spraying, the insect population base was investigated at five points on the diagonal of each treatment area, and 10 crops were investigated at each point. 3 days, 7 days, and 14 days after spraying, investigate the control effect, record the number of live insects, and calculate the control effect.

[0060] Table 4 The results of the field efficacy test of dipropetran and cyclopyrid on cabbage aphids

[0061]

[0062] Table 5 The results of the field efficacy test of dipropetran and cyclopyrid on cucumber whitefly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com