Yellow chicken raw material production method applicable to Chinese food cooking mode and product

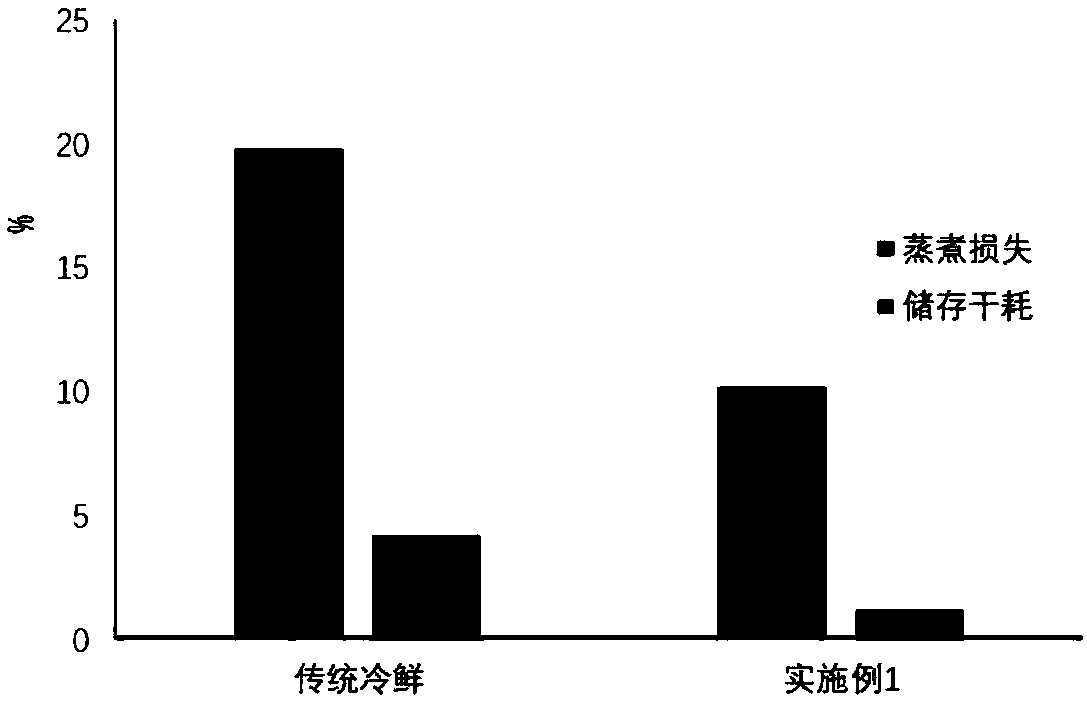

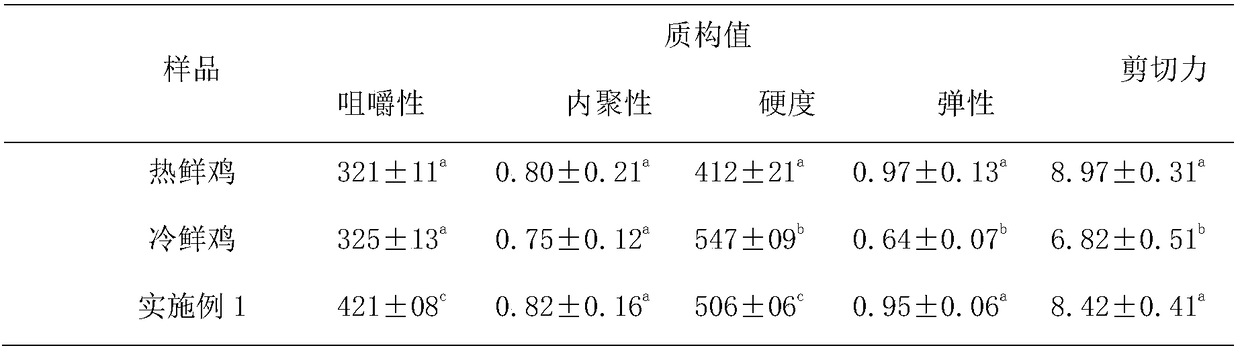

A technology of yellow feather broiler and cooking method, which is applied in the fields of processed meat, food preservation, food ingredients, etc., can solve the problem that cold fresh yellow feather broiler cannot be accepted by consumers, affects the cooking effect and dish taste, and is difficult to meet the demand of yellow feather broiler. and other problems to achieve the effect of improving muscle shear force, reducing cooking loss, and improving chicken texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the yellow-feathered broiler raw material production method suitable for the Chinese food cooking method of the present invention comprises the following steps:

[0038] 001. Slaughtering, dehairing, and evisceration: Slaughter after passing the quarantine, put it in warm water for a short time to scald for depilation, and open the poultry to remove the viscera.

[0039] 002. Cut the sternum: Cut the chicken breast along the direction of the keel of the chicken breast, and unfold the chicken body into a flat shape, similar to the state of the Fengla chicken after plastic surgery.

[0040] 003. High-pressure washing: use high-pressure water to wash the remaining viscera in the chicken cavity, such as chicken lungs, etc., and thoroughly rinse the chicken cavity.

[0041] 004. Ozone water disinfection: Soak the chicken body in electrolytic ozone water for disinfection, and drench the water.

[0042] 005. Skin-fit packaging: the chicken cavity is covered with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com