A hydrogenation catalyst based on carbon nanotube/alumina composite carrier and its preparation method and application

A technology of hydrogenation catalyst and composite carrier, applied in metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problem of difficult reduction of spinel and failure of active components , the strong interaction between the carrier and the active component, etc., to achieve the effect of improving the active component, improving the utilization rate, and strengthening the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

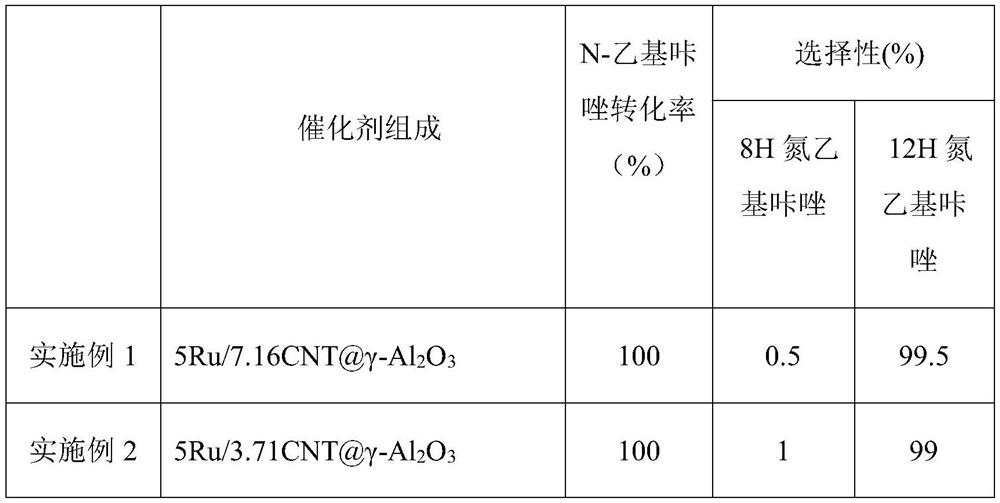

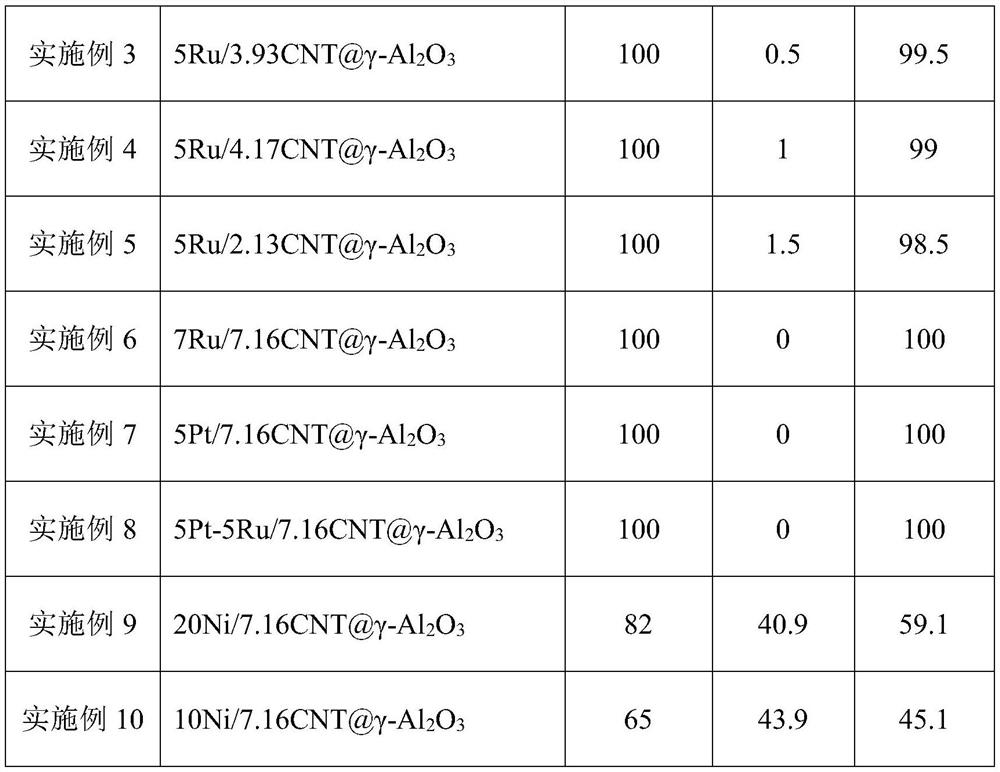

Examples

Embodiment 1

[0033] 1. Mix 10g 40-60 mesh γ-Al 2 o 3 Add 3g of ethanol to disperse, mill on a ball mill for 40min to achieve surface activation, and make activated γ-Al 2 o 3 ;

[0034] 2. Take 4g of pseudoboehmite and add 40ml of 0.1mol / L dilute nitric acid to configure AlOOH sol, take 1g of carboxylated carbon nanotubes and ultrasonically disperse them in 15ml of water, and fully stir and mix them with AlOOH sol under ultrasonic to obtain CNT- AlOOH sol mixture;

[0035] 3. Combine the CNT-AlOOH sol mixture obtained in step 2 with the activated γ-Al obtained in step 1 in batches 2 o 3 Mixing, when the sol solution soaks the γ-Al 2 o 3 Stop adding liquid on the surface, and the γ-Al coated with CNT-AlOOH sol mixture 2 o 3 Move it into a drying oven, dry at 105°C for 2 hours, take it out and continue to use CNT-AlOOH sol mixture to infiltrate γ-Al 2 o 3 On the surface, dry at 105°C for 2 hours and repeat several times to obtain 15g of γ-Al with CNT-AlOOH sol mixture attached 2 ...

Embodiment 2

[0039] 1. Mix 10g 40-60 mesh γ-Al 2 o 3 Add 3g of ethanol to disperse, mill on a ball mill for 40min to achieve surface activation, and make activated γ-Al 2 o 3 ;

[0040] 2. Take 4g of pseudoboehmite and add 40ml of 0.1mol / L dilute nitric acid to form AlOOH sol, take 0.5g of carboxylated carbon nanotubes in 7.5ml of water for ultrasonic dispersion, and fully stir and mix with AlOOH sol under ultrasonic to obtain CNT -AlOOH sol mixture;

[0041] 3. Combine the CNT-AlOOH sol mixture obtained in step 2 with the activated γ-Al obtained in step 1 in batches 2 o 3 Mixing, when the sol solution soaks the γ-Al 2 o 3 Stop adding liquid on the surface, and the γ-Al coated with CNT-AlOOH sol mixture 2 o 3 Move it into a drying oven, dry at 105°C for 2 hours, take it out and continue to use CNT-AlOOH sol mixture to infiltrate γ-Al 2 o 3 On the surface, dry at 105°C for 2 hours and repeat several times to obtain 14.5g of γ-Al with CNT-AlOOH sol mixture attached 2 o 3 ;

[0...

Embodiment 3

[0045] 1. Mix 10g 40-60 mesh γ-Al 2 o 3 Add 3g of ethanol to disperse, mill on a ball mill for 40min to achieve surface activation, and make activated γ-Al 2 o 3 ;

[0046] 2. Take 3g of pseudoboehmite and add 30ml of 0.1mol / L dilute nitric acid to form AlOOH sol, take 0.5g of carboxylated carbon nanotubes in 7.5ml of water for ultrasonic dispersion, and fully stir and mix with AlOOH sol under ultrasonic to obtain CNT -AlOOH sol mixture;

[0047] 3. Combine the CNT-AlOOH sol mixture obtained in step 2 with the activated γ-Al obtained in step 1 in batches 2 o 3 Mixing, when the sol solution soaks the γ-Al 2 o 3 Stop adding liquid on the surface, and the γ-Al coated with CNT-AlOOH sol mixture 2 o 3 Move it into a drying oven, dry at 105°C for 2 hours, take it out and continue to use CNT-AlOOH sol mixture to infiltrate γ-Al 2 o 3 On the surface, dry at 105°C for 2 hours and repeat several times to obtain 13.5g of γ-Al with CNT-AlOOH sol mixture attached 2 o 3 ;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com