Method for preparing 3-isocyanatopropyltrimethoxysilane

A technology of esteryl propyltrimethoxysilane and trimethoxysilane, which is applied in the field of preparation of 3-isocyanatopropyltrimethoxysilane, and can solve problems such as difficult control of by-products, harsh reaction conditions, and long reaction time , to achieve the effects of safe production, easy control, good product quality and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

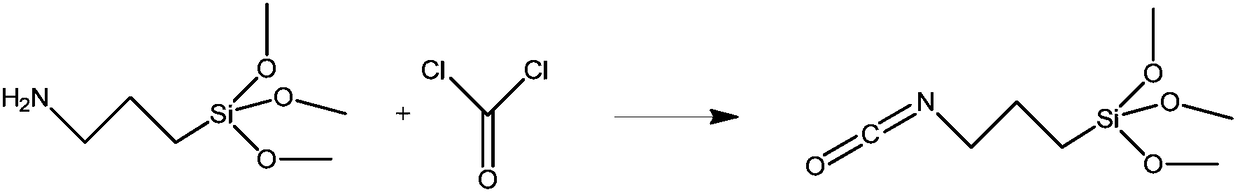

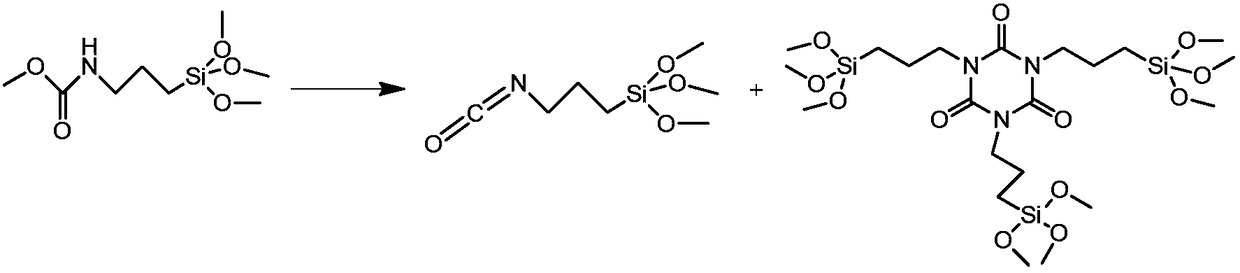

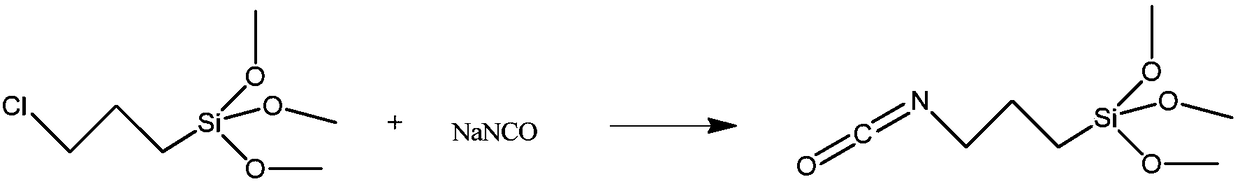

Method used

Image

Examples

Embodiment 1

[0033] Add 126 g of methyl [3-(trimethoxysilane)propyl] carbamate, 59 g of triethylamine and 400 ml of toluene into a 1 L reaction kettle, and stir. Under nitrogen protection, add 45g of methyltrichlorosilane dropwise at 20-40°C, after the dropwise addition, slowly raise the temperature to 95-100°C, react for 1h, take samples for analysis, [3-(trimethoxysilane)propyl]carbamic acid When the GC content of methyl ester is less than 1%, the heating can be stopped. Cool down to 20-30°C and filter, and wash the filter cake twice with 100ml of toluene. The filtrates were combined, toluene was concentrated, and 107 g of the product was evaporated under reduced pressure, with a yield of 96% and a content of 98%.

Embodiment 2

[0035] Put 150 g of [3-(trimethoxysilyl)propyl]methyl carbamate, 96 g of triethylamine and 400 ml of toluene into a 1L reaction flask, and stir. Under nitrogen protection, add 75g of methyltrichlorosilane dropwise at 20-40°C, after the dropwise addition, slowly raise the temperature to 95-100°C, react for 1h, take samples for analysis, [3-(trimethoxysilane)propyl]carbamic acid When the GC content of methyl ester is less than 1%, the heating can be stopped. Cool down and filter, and the filter cake is washed twice with 150ml of toluene. The filtrates were combined, the solvent was evaporated, and 127 g of the product was evaporated under reduced pressure, with a yield of 95.8% and a content of 98%.

Embodiment 3

[0037] Add 169 g of [3-(trimethoxysilane)propyl] methyl carbamate, 111 g of triethylamine and 400 ml of toluene into a 1 L reaction kettle, and stir. Under nitrogen protection, add 106g of methyltrichlorosilane dropwise at 20-40°C, after the addition is complete, slowly raise the temperature to 95-100°C, react for 1h, take samples for analysis, [3-(trimethoxysilane)propyl]carbamic acid When the GC content of methyl ester is less than 1%, the heating can be stopped. Cool down and filter, and the filter cake is washed twice with 150ml of toluene. The filtrates were combined, the solvent was concentrated, and 142 g of the product was evaporated under reduced pressure, with a yield of 95.3% and a content of 97.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com